Forming is one of the important manufacturing techniques in modern engineering. Nearly many objects that are being used in our daily life are manufactured from forming methods or processes.

Some examples are the ball used in a ballpoint pen, hydraulic and pneumatic valves, toothpaste containers, cooking vessels, chains, fan blades, etc.

Metal forming is widely used around the globe due to its positive advantages like cost-effectiveness, improved mechanical properties, high strength, increased productivity, and improved material saving.

Forming has found its applications in many fields such as aerospace, automotive, and defense industries.

A typical automobile vehicle uses parts like wheel rims, the body, the chassis, the valves made by forming method.

In this article, we will study what is Forming and What are different types of Forming processes? in detail. And next, we will also see the advantages, disadvantages, and applications.

Note: The PDF of this article you can download at the end of the articles.

Forming Process History

The discovery of a copper pendant in northern Iraq around 8,700 BCE has been established as the first known industrial metal mining and working operation. Copper mining has been documented in the Americas as early as 4000-5000 BCE in Lake Michigan.

Metals grew increasingly significant to their individual civilizations over time, becoming essential to building operations, and metalworking became an important component of society.

The art of working with metal now encompasses a wide range of professions and industries.

Metal forming and shaping is a specialty for many people. Since ancient times, techniques have evolved significantly, and machines now perform the majority of metal shaping.

For example, Roll forming is accomplished using high-quality roll forming equipment. Roll forming is a method of bending a continuous strip of metal into a certain shape.

A roll forming machine is made up of a series of rolls that bend metal into shape in a continuous motion. Only a little portion of the metal is bent by each pair of rolls, also known as strands. The metal is rolled till it fulfills the requirements.

The evolution of metalworking can be seen in the art of roll-making. The usage of a roll forming machine and other roll forming equipment are examples of how the metalworking industry has progressed through time.

What is Forming Process?

Metal forming is a process of manufacturing components of desired shapes by deforming the material plastically, by the application of compressive force, bending or shear force, tensile force, or combinations of these all forces together, without adding or removing material.

Types of Forming Process

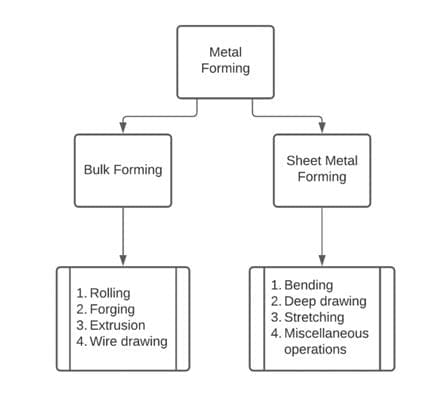

Forming Process has been classified into two groups; Bulk-forming and Sheet metal forming.

Further, the detailed classification of the forming process as you can see in the layout above.

Now we will get to know all types in detail.

#1. Bulk forming

Bulk-forming is a method of producing materials large volumes of products whose surface area is less than the volume ratio.

Here, to accomplish the machining, tensile forces, compressive forces, shear forces, or a combination of any two is processed.

It is carried out in machinery which has a set of tools and dies. The use of a tool and the die itself makes us understand that the die has the same shape as the output to be produced and the tool is pressed against the die to generate the shape on the material.

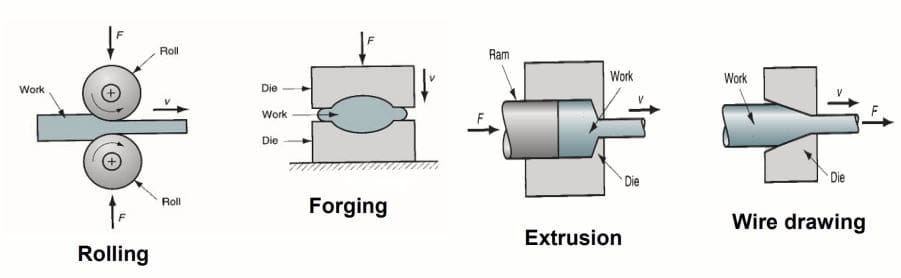

The bulk-forming involves processes named Rolling, Forging, Extrusion, and Drawing as its work processes.

1.1 Rolling

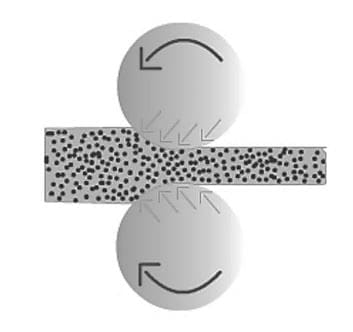

Rolling is a typical forming process used to manufacture semi-finished products such as rods, sheets, and plates, and finished products such as angles, U-profiles, and profiles. Rolling can be done both hot and cold.

In this process, the billet in the form of a slab is compressed between two rolls that rotate in the opposite direction, thus reducing the thickness of the billet and fabricating it to a new shape. The rotating rollers pull the slab into space and compress it. The final product is the reduced size of the billet.

A variety of rolling mills have evolved over time for the production of different shaped articles. Each is described below.

1.2 Two-High Rolling Mill

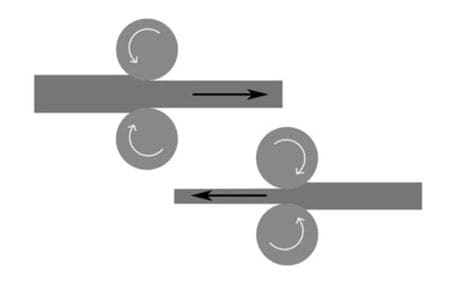

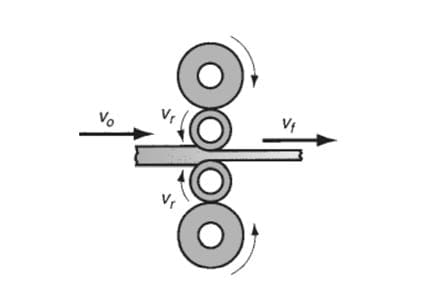

The Two-High Rolling Mill is constructed out of a three separate stand with two horizontal rolls stacked one on top of the other.

One or both rollers are adjustable in this type of mill. The metal is passed between two rollers that rotate at the same speed but in different directions during operation.

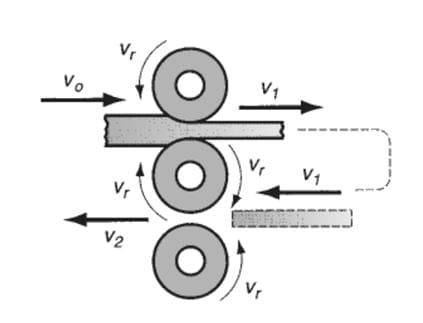

1.3 Three-High Rolling Mill

In the case of the Three-High Rolling Mill, there are three rolls, one on top of the other. Two rolls will be used at a time for a single pass. In this case, the roll direction will not be altered.

The sheet will be relocated to the bottom two rolls for a further reduction once the top two rolls have been used for the first reduction. This cycle is repeated until the desired decrease is achieved.

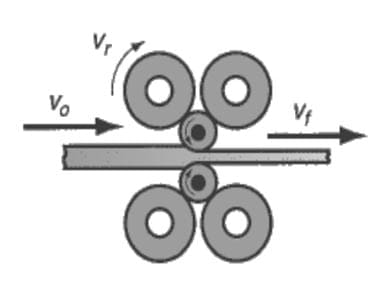

1.4 Four-High Rolling Mill

The Four-High Rolling Mill consists of two small rolls used to reduce thickness and two large backing rolls used to support the small rolls.

Because the roll-sheet contact area is reduced with short rolls, the roll force required is lowered.

The large backing rollers are needed to lessen the elastic deflection of the small rolls when the sheet is passed between them.

1.5 Cluster Mill

A Cluster Mill is comprised of two operating rolls and four or more backing up rolls.

The number of back-ups or supporting rolls necessary is determined by the amount of support needed for the working (small diameter) rolls. Cluster mills are normally employed in cold-rolling operations.

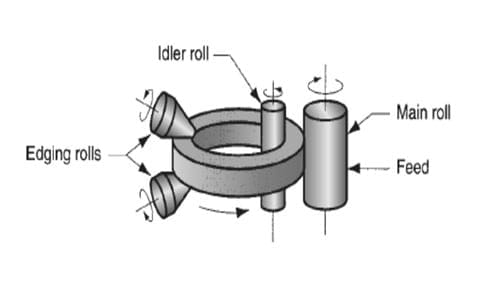

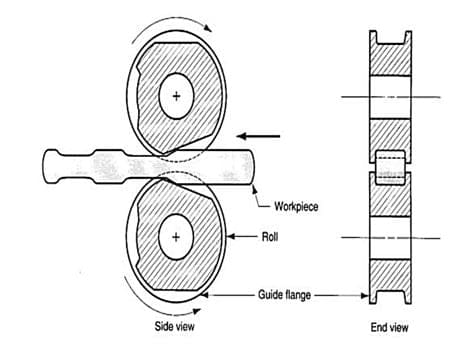

1.6 Ring Rolling

Ring Rolling is a forming method that involves rolling a thick-walled ring component of a lower diameter into a thin-walled ring of a greater diameter.

As the thick-walled ring is compressed, the deformed material elongates, causing the ring’s diameter to increase.

1.7 Forging

Forging is a bulk-forming method in which compressive and tensile forces are applied to a workpiece or billet to fabricate it into a final product using a pair of tools called a die and punch.

Open or closed dies can be used for forging. In most cases, open die forging is used to shape raw materials into a shape suitable for later forming or machining.

In this process, the billet is compressed between two dies. The dies contain a shaped contour that is to be generated on the final product. On compression of the billet between a pair of dies, the shape is imparted on the billet, thus obtaining the final product.

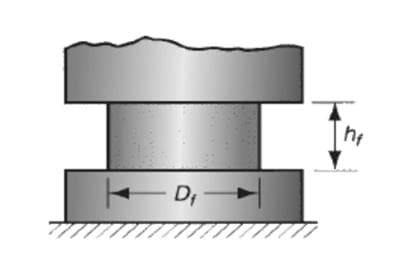

1.7.1 Open Die Forging

For operations such as drawing out, thinning, and so on, Open Die Forgings are done with a pair of flat-facing dies.

Open die forging is a vital technology in a variety of industries.

It enables the rough and finishing shape of metals, most notably steel and steel alloys. It necessitates a die with open sides that allows the workpiece to move freely in a lateral manner when hit. This design also enables the forging of very big workpieces.

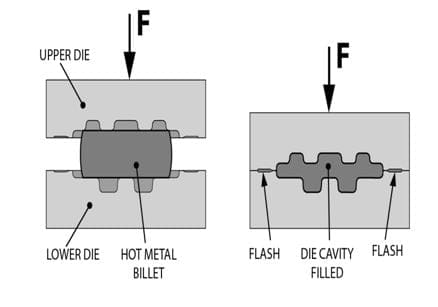

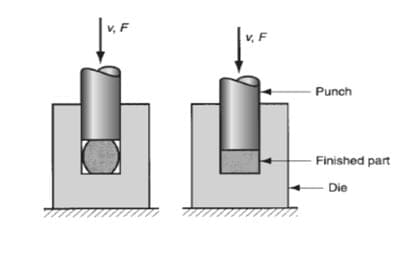

1.7.2 Closed Die Forging

Closed Die Forging is accomplished by compressing a billet of raw material into a cavity produced between two shaped dies.

The shape of the die cavity is achieved by forming products. Closed die forming is used to make valve parts, pump parts, tiny gears, connecting rods, spanners, and other items.

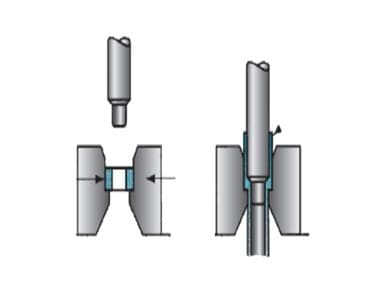

1.7.3 Coining

The process of coining is the application of compressive stress to the raw material’s surface in order to impart unique shapes from the embossing punch.

Examples are printed metal coins and medallions.

1.7.4 Impression Die Forging

In Impression Die Forging, the die surfaces have a form that is imparted to the workpiece during compression, greatly restricting metal flow. The additional distorted material outside the die impression is referred to as flash. This will be removed later.

Impression dies forging is incapable of producing products with tight tolerances.

To attain the required accuracies, machining is usually required.

The forging process produces the fundamental shape of the item, with further machining performed on those parts of the part that require precision finishing, such as holes and threads.

1.7.5 Flash Less Forging

In the Flash Less Forging technique, the workpiece is totally limited within the die in flashless forging, and no flash is produced. The amount of initial workpiece utilized must be precisely managed so that it matches the volume of the die cavity.

This flash-less forging technique is appropriate for making basic and symmetrical part geometries, as well as working materials such as Al, Mg, and their alloys, due to the demands.

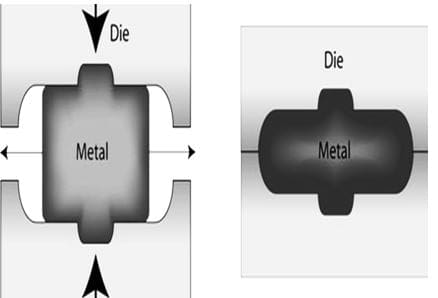

1.7.6 Roll Forging

Roll Forging is a shaping method that is used to decrease the cross-section of a cylindrical or rectangular rod by passing it through a set of opposed rollers with matching grooves in relation to the desired shape of the finished item. Though it also combines rolling and forging, it is categorized as a forging operation.

In this process, the rollers spin partly depending on the degree of deformation. Roll-forged products are often stronger and have the required grain structure as compared to the machining of the same item.

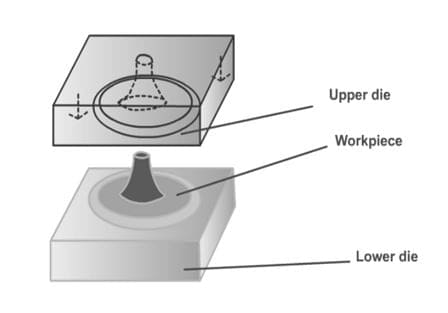

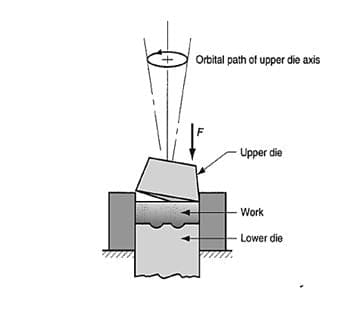

1.7.7 Orbital Forging

In Orbital Forging, the shape is imparted to the material in this method by a cone-shaped top die that is synchronously rolled and pushed into the work. A lower die is used to support the work.

Because of the cone’s slanted axis, only a tiny portion of the workpiece surface is squeezed at any point of the forming process.

The region under compression circles as the higher die turns. There is a significant reduction in press load demand caused by partial strain contact at any step of forming.

1.7.8 Isothermal Forging

Isothermal Forging is a hot-forging technique in which the work is kept at a high temperature during the forming process. The forging dies are likewise kept at the same high temperature. By eliminating the coldness of the work coming into touch with the cool die surfaces, the metal flows more easily and the effort required is lowered.

The technique is more costly than traditional forging and is typically used for difficult-to-forge metals such as Ti, superalloys, and complicated component forms. To avoid quick oxidation of the die material, the operation is carried out in a vacuum or inert environment.

1.8 Extrusion

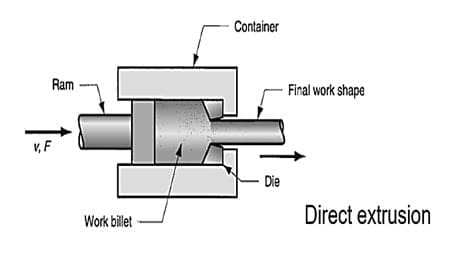

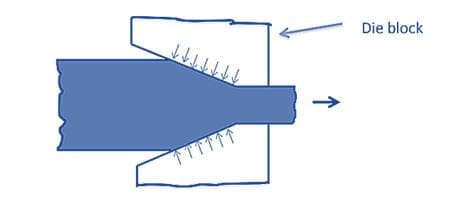

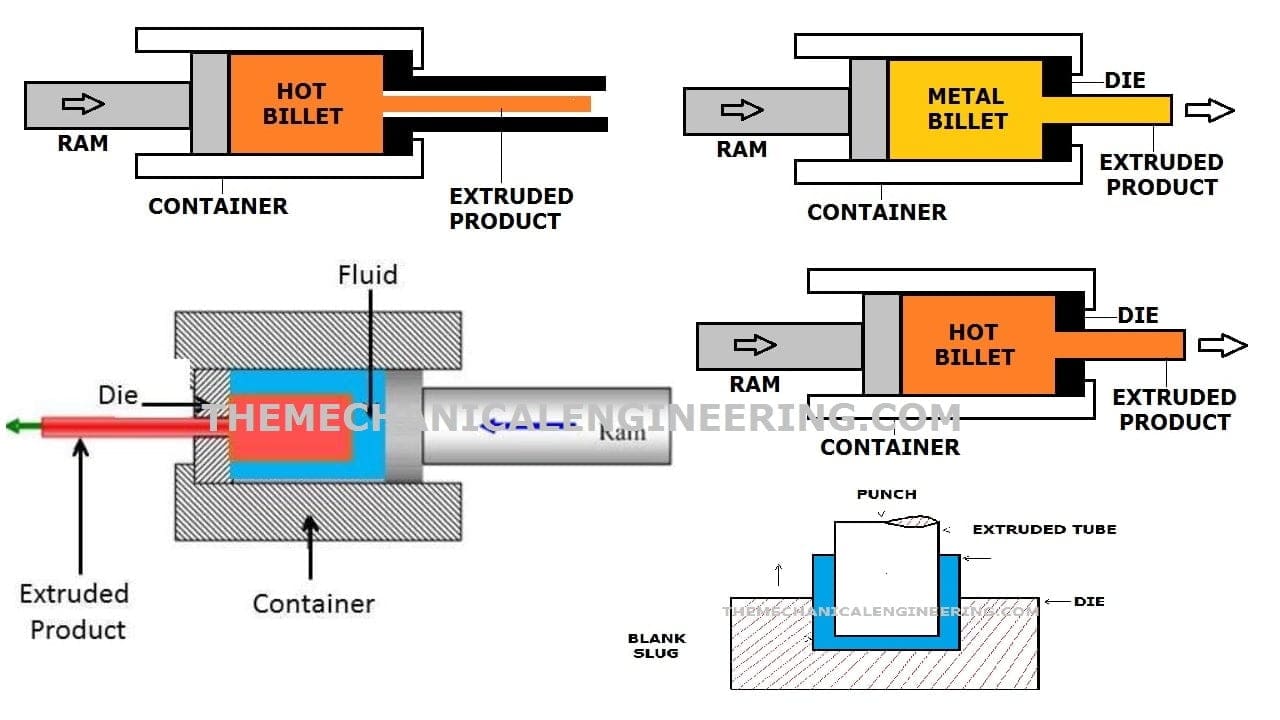

Extrusion is a bulk-forming procedure that involves forcing or compressing work metal through a die hole to produce a desired cross-sectional shape.

Extrusion is typically distributed into two work manners. One as Direct or forward extrusion and the other as Indirect or backward extrusion.

1.8.1 Direct or forward extrusion

In direct extrusion, a metal billet is first loaded into the container. The container has a die hole of shaped contour. A ram is then used to force the metal billet through the die hole to produce the article.

Extruded products include tubes, cans, cups, small size gears, shafts, etc.

Some portion of the billet always remains at the end of every extrusion and is called the butt.

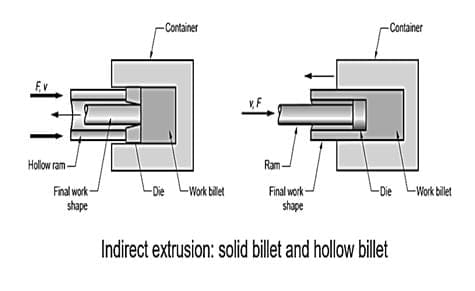

1.8.2 Indirect or backward extrusion

Instead of being mounted on the container, the die is mounted on the ram. The metal flows through the die hole on the ram side in the opposite direction of the ram’s movement as it is compressed by the ram.

There is no friction at the contact since there is no relative motion between the billet and the container, hence the ram force is smaller than in direct extrusion.

1.9 Wire drawing:

The wire drawing process is used to make small diameter wires from rods by reducing their diameter and stretching their length with tensile force.

Wire drawing is used to make musical strings. Tube drawing can be used to create seamless tubes.

In this process, a rod, or bar is pulled through a die hole to form the desired thickness of wire, reducing their cross-section area.

2. Impact extrusion

Impact extrusion is always carried out in cold form. Backward impact extrusion permits for very thin walls. Manufacturing toothpaste tubes, for example, or battery boxes.

It is done at faster speeds and with shorter strokes. Impact pressure, rather than exerting pressure, is used to extrude the billet through the die. However, impacting can be accomplished by forward or backward extrusion or a combination of the two.

2.1 Hydrostatic extrusion

In the hydrostatic extrusion technique, the billet is surrounded by fluid within the container during the process, and the fluid is pressured by the ram’s forward motion. Because of the fluid, there is no friction inside the container, and friction at the die hole is minimal. Special fluids and methods must be employed while working at high temperatures.

The ductility of a material rises when there is hydrostatic pressure on it and no friction. As a result, this approach may be utilized on metals that are too fragile for traditional extrusion procedures.

This method is used on ductile metals, with large reduction ratios conceivable.

#2. Sheet metal forming

Sheet metal forming involves the application of tensile and shears forces to fabricate sheets, plates, and strips to a desired possible shape using a set of tools. The punch and die are used as tools in the fabrication process.

Sheet metal forming is associated with operations; Bending, Drawing, Shearing, Blanking, and Punching to produce the materials.

The sheet forming method uses plastic sheet deformation techniques such as Deep Drawing, Cutting, Bending, Hemming, Flanging, Curling, Stretch Forming/Stretching, Stamping.

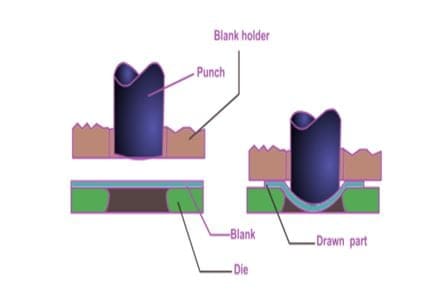

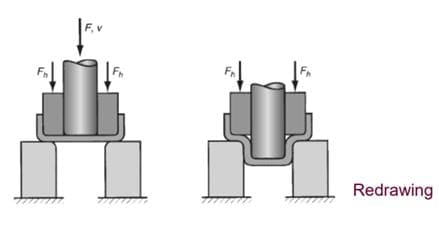

2.1 Deep drawing:

Deep drawing is a sheet metal process in which sheet metal is forced into a cup of hollow shape using tensile and compressive forces without changing its thickness.

In this process, the sheet is placed over the die opening and pushed into it with a punch. A blank holder is used to hold the sheet flat on the die surface.

In many cases, the alteration required to create that part will be substantial (the drawing ratio is very high). In such cases, the part’s complete forming necessitates more than one deep drawing step.

Any additional drawing steps required to complete the drawing operation are referred to as Redrawing.

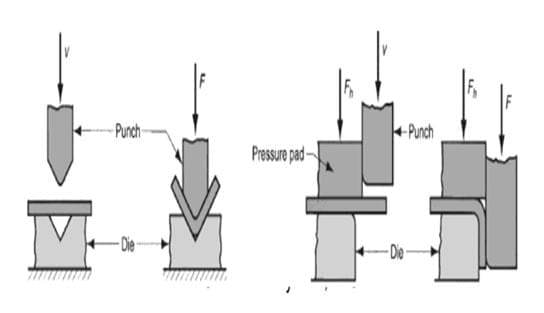

2.2 Sheet bending:

Sheet bending is defined as metal straining around a straight axis. The metal on the inner edge of the neutral plane is compressed while the metal on the outer edges of the neutral plane is stretched during the bending operation. The thickness of the sheet metal does not change as a result of bending.

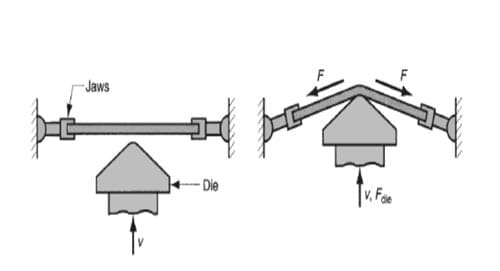

2.3 Stretching or Stretch forming:

Stretch forming is a sheet metal forming process in which the sheet metal is intentionally stretched and bent at the same time to change its shape.

The sheet is held at both ends by jaws or draw beads and then stretched by punch, causing the sheet to be stressed above its yield strength and fabricating it to the desired shape.

The metal has been plastically distorted when the strain is released. The combined impact of stretching and bending causes the part to have a lower spring back.

Metal Forming Process Video Lecture:

Applications of Metal Forming Process:

The metal forming technique is used to produce seamless tubes, rods, and turbine rings. It is also used to create cement kilns.

This forming process can be used to create bearings, plates, steel sheets, and numerous components for an automobile.

This method is also used to make missile and aircraft components and also used to make hinges, bolts, and nails.

Advantages of Metal Forming Process:

The following advantages of forming processes are as follows:

- Articles with increased strength.

- Very less material wastage.

- A smaller components with high strength can be manufactured.

- Articles produced are accurate in dimensions.

- Uniform rate of forming.

- Great surface finish.

- Less machining time compared to conventional metal removal method.

- Improved mechanical properties.

Disadvantages of Metal Forming Process:

The following disadvantages of forming processes are as follows:

- The requirement of Power is high.

- There is high mechanical forces requirement.

- Strain hardening of the work material is a limit to the amount of forming.

- The brittle material cannot be manufactured in this process.

- There is also use of heat treatment process in metal forming some times.

Internal Resources for You:

- Forging vs Casting

- Hot Working Process

- Cold Working Process

- Forging Tools and their Uses

- Centrifugal Casting

- Buffing and Polishing Process

- Grinding Machine

- Lathe Machine

- Milling Machine

- Drilling Machine

- Planer Machine

- Slotter Machine

Reference [External Links]:

- https://www.iitg.ac.in/engfac/ganu/public_html/Metal%20forming%20processes_full.pdf

- https://www.sciencedirect.com/topics/materials-science/metal-forming-process

- https://www.youtube.com/watch?v=IWwZpDWccHE

Conclusion:

Here we finally studied all the metal forming processes in detail. I hope you have understood this topic in detail. I have also explained the different topics of Manufacturing Technology. You can check those articles too.

Discussion about this post