What is Manometer?

A manometer is a popular device utilized for estimating the fluid pressure about an exterior origin which is normally evaluated to be the globe’s environment.

An easy manometer can be assembled by partly restoring an apparent plastic duct with a coloured fluid to enable the fluid level to be handily examined.

The duct is again intended into a U-shape and repaired in a vertical situation. The categories of the liquid in the two upright sections should be comparable at this level, as they are presently perceived to be the same difficulty.

This category is accordingly substantial and identified as the zero level of the manometer. The instrument is positioned against the measuring plate to enable any disparity in the length of the two sections.

This length differential can exist utilized rapidly to give rise to the comparable comparison between various experiment stresses. This kind of manometer can furthermore be employed to evaluate the absolute strength when the consistency of the liquid in the manometer is remembered.

How does the Manometer work?

The working of a manometer is pursued as; The meter in the instrument includes a metal shaft or cylinder. During the measurement of a gas or fluid, the flexible cylinder of the gauge is clutched.

Thereafter, the shaft is distorted, which is restored to the instrument, enabling you to examine the outcome.

This instrument contains a U formed duct or tube in which the fluid is compressed. This is utilized to assess the pressure which is unspecified by the balancing gravity force and momentum due to gravity.

The scales are created on the tube in phrases of mm.

The principle on which a manometer works with the vapour or fluid pressure estimate is incredibly easy.

Hydrostatic stability in the instrument indicates that the stress when fluid is at rest is comparable at any level.

For Illustration, if both the ends of the U-tube live left open to the environment then the strength on each aspect will be identical.

Advantages of Manometer:

- It is economical and adequate for low-pressure entreaty.

- It has a simple construction, decent perceptivity, nice precision and reasonable procedure and formation.

- The manometers do not have to be calibrated against any criterion; the stress variation can be evaluated from the early principles.

- The manometer is accessible for a huge range of restoring liquids of fluctuating certain gravity.

Disadvantages of Manometer:

- Manometers are vast and thick

- It needs grounding

- No fixed quotation is accessible

- In the manometer, the omission is submitted due to moisture

- It has no over a latitude preservation

- It has a miserable energetic response

Different Types of Manometer and their uses:

There are mainly three different types of manometers and those are:

- Simple manometer

- Differential manometer and

- Micromanometer

#1. Simple Manometer:

A simple manometer contains a pipe configuration where one edge of the duct is attached to the level in the liquid in which the pressure is to be assumed and the further edge is maintained open to the environment.

Generally, It contains a glass tube or pipe having one edge connected to a point and the other end continuing open. These types of manometers can be used to differentiate the cadenced pressure or void pressure.

Different Types of Simple Manometer are:

- U-tube (For Gauge and Vacuum Pressure)

- Piezometer

- Sensitive or Inclined tube and

- Single Column Manometer

#1.1 U-Tube Manometer:

The U-tube manometer is the incentive for the pressure measurement equipment. Its name comes from the U-shaped construct when the two edges of an adjustable duct full of fluid are put forward to protect the fluid from attaining out of the edges.

The U-tube manometer occurs as a ‘liquid’ equilibrium manometer. The height variation is estimated on a graduated plating.

The duct carries the metal mercury or any different liquid or fluid whose particular gravity is extensively elevated than the certain sincerity of the fluid whose strength is to be estimated.

For gauge pressure: In the gauge pressure measurement the U-tube manometer is used to equalize the weight of the fluid on one side of the u-tube against the strength instructed to the other side of the tube.

The distinction in the elevation of the fluid exemplifies the pressure propelling the fluid down to one side of the tube and up the other side.

For vacuum pressure: In the vacuum pressure when a vacuum is connected to one side of the U-tube, the watery increases in that side of the tube and plummets on the further side. The length variation which extensively amounts to the readings above and below zero level reflects the quantity of vacuum. The devices which operate these principles are called manometers.

U-Tube Manometer Advatages:

- The strategy of using U – Tube manometer is very easy.

- Pressure measurement with U – Tube manometer is relatively economical.

- U – Tube manometer will deliver the detailed pressure examination.

- U – Tube manometer is very understandable in construction.

U-Tube Manometer Disadvantages:

- The fluid will be uncovered to the environment in a u-tube manometer and accordingly, the fluid must be neat and non-toxic.

- In different when head will be minor as it will be extremely tough to calculate the pressure if elevation will be small.

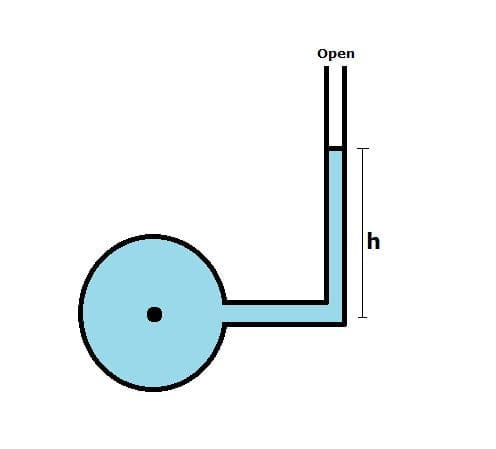

#1.2. Piezometer:

The piezometers are devices that are used to measure the fluid pressure in a system by measuring the elevation to which a column of the fluid increases against earnest and it is also called geotechnical detectors and It is used for the measurement of pressure of the pore water through piezometric levels on the surface.

The piezometer is designed to measure the pressure of pore water in the ground, establishments, solid structures and gravel fill.

Piezometer works on the principle of conversion of liquid pressure to a regularity signal via a diaphragm and a stressed steel cord.

When a magnetic coil is used for excitation, the steel cord vibrates at its normal frequency. A piezometer is used in foundations, monitoring of soil barriers, strength and examination of soil and formation supervision.

#1.3. Sensitive manometer or Inclined tube manometer:

An inclined tube or a sensitive manometer is a reasonable and economical device. The Inclined tube manometer is normally utilized for calculating differential pressure in a hollow. It corresponds to a U-tube Manometer.

This device comprises two intercommunicating crates restored with filtered liquid.

These types of manometers give better readability by lengthening an upright differential with a likely to demonstrate column, providing additional graduations per unit of upright length and improving the instrument’s perceptivity and precision.

The sensitive manometer is useful for conserving the most accurate pressure points for industries’ steam requisitions.

The working principle of the manometer comprises the measurement of the pressure the one tube of the Inclined tube manometer features into a puddle and the other one of the manometer is inclined as per the requirements of angle.

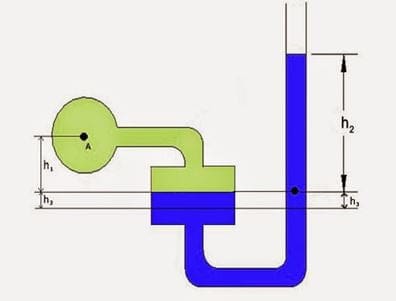

#1.4. Single Column Manometer:

The single-column manometer is a modified version of a U-tube manometer in which one side of the manometer is a big waterhole and the other side of the manometer is a minor duct or tube which is upright to the environment.

The Single column manometer immediately provides the strength by assessing the length in the other component and expected to the huge cross-sectional region of the waterhole, for any deviation in pressure, the alteration can be excluded.

Normally there are two kinds of single column manometer based on the component of the manometer, a Vertical single column manometer and an Inclined single column manometer.

2. Differential Manometer:

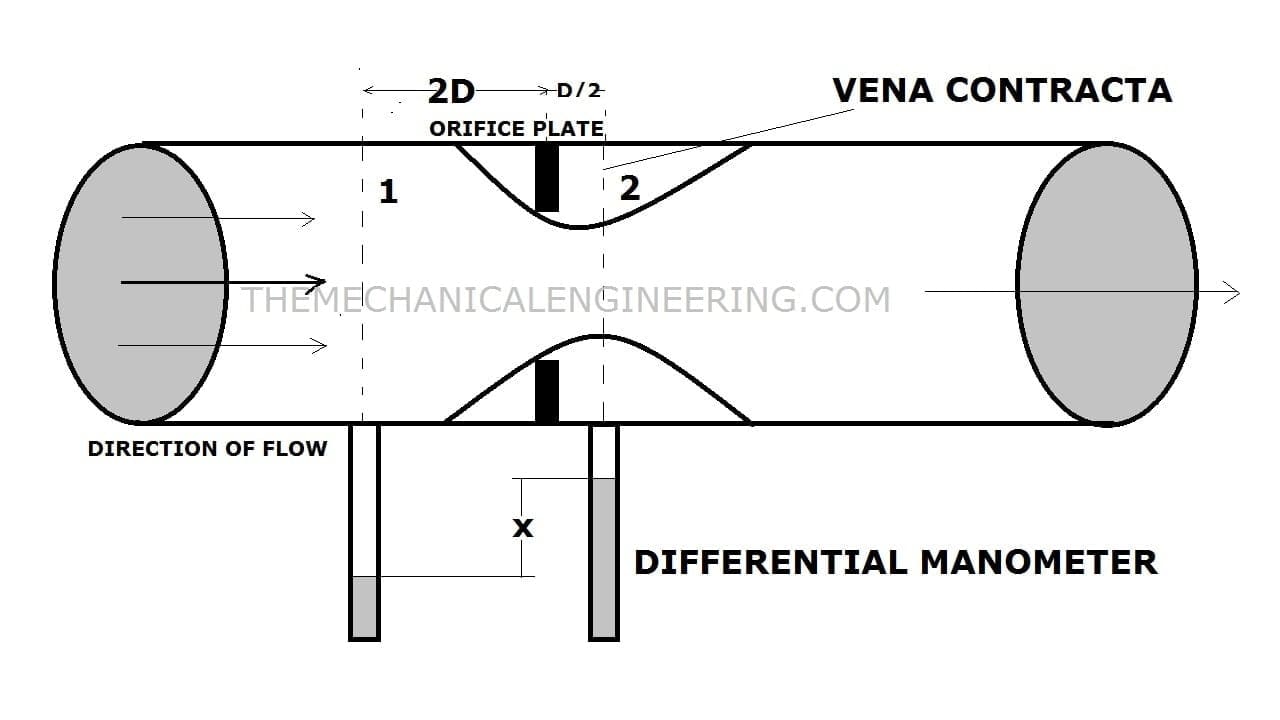

The differential manometer is equipment that is used to compare the pressure instead of measuring the pressure. It is mostly used to measure the pressure difference between the two points or two tubes.

It is also used to inspect the leaks in the pipes as the leakage leads to pressure unevenness hence unbalancing of the manometric liquid.

The water level in a compartment is also gauged by this manometer and it is also employed as a fluid level indicator in boiler equipment.

The differential manometers have a simple construction and they are cost-effective and easy to maintain. Differential manometers can be easily replaced and have little or no operating cost.

Differential manometers are categorized into two kinds:

- U-tube differential and

- Inverted U-tube differential.

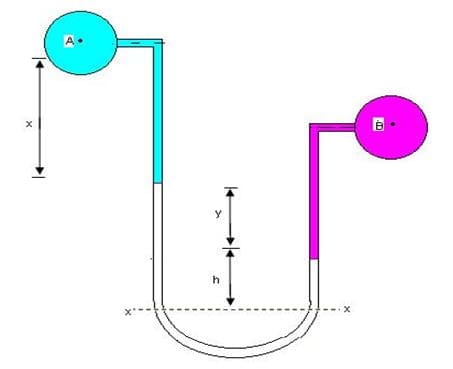

#2.1 U-tube differential manometer:

The U-tube differential manometer encloses a glass duct intent into a U shape. Both the ends of the U-tube in the manometer are attached to the levels whose pressure is to be measured.

In the U-tube, a type of fluid known as manometric fluid is injected. The manometric fluid has higher specific gravity than the fluids present in the pipe.

Primarily, mercury is used as a manometric fluid as it has a high specific gravity, does not stick to the glass and is totally visible. It can also be used at a large span of temperature.

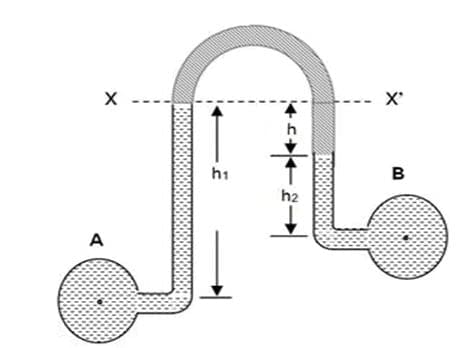

#2.2 Inverted U-tube differential manometer:

The inverted U-tube manometer is also used for measuring the differences in the pressure of the fluids.

The vacuum above the fluid in the manometer is restored with air which can be conceded or evicted through the faucet on the top; this is to modify the level of the fluid in the tube of the manometer.

Mercury is widely used as a manometric fluid because it has some integrity under typical circumstances like permanent viscosity.

#3. Micromanometer:

Generally, it is an apparatus used to demonstrate and measure the pressure or a manometer is equipment that computes air pressure utilizing a container with a “U”-shaped duct that is open at one or both ends.

The elevation of the liquid on the open side of the U-tube will be bigger on that viewpoint when air pressure is smaller than the vapour pressure and deeper on the upright side when the air pressure surpasses the vapour pressure.

Micromanometers calculates the total, static and velocity pressures, as well as pressure, lowers across the diffusers, fans, filters and coils.

Internal Resources:

- Venturi Meter

- Orifice Meter

- Types of Fluid Flow

- Pump vs Compressor

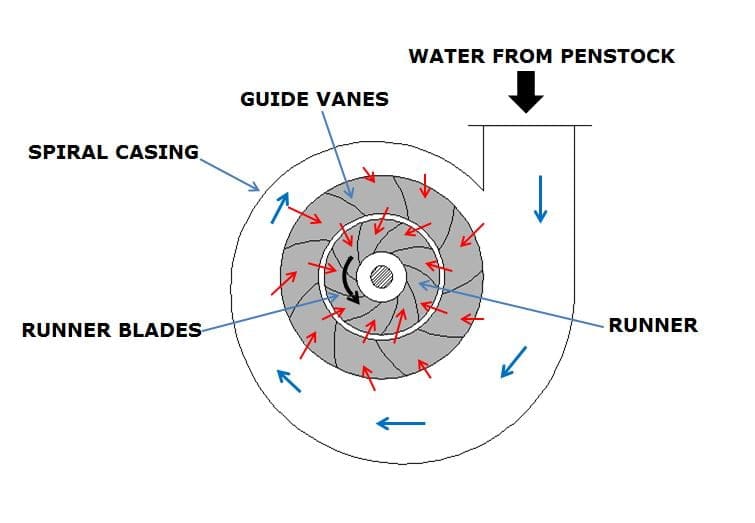

- Francis Turbine

- Kaplan Turbine

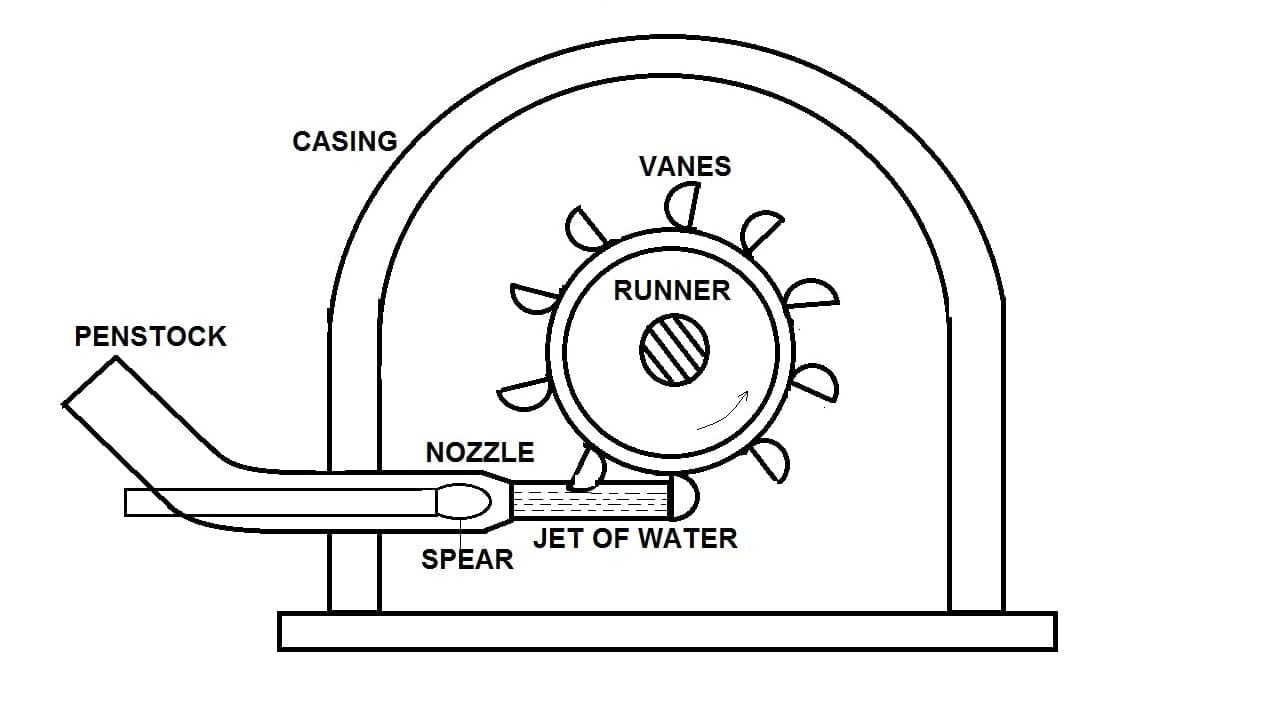

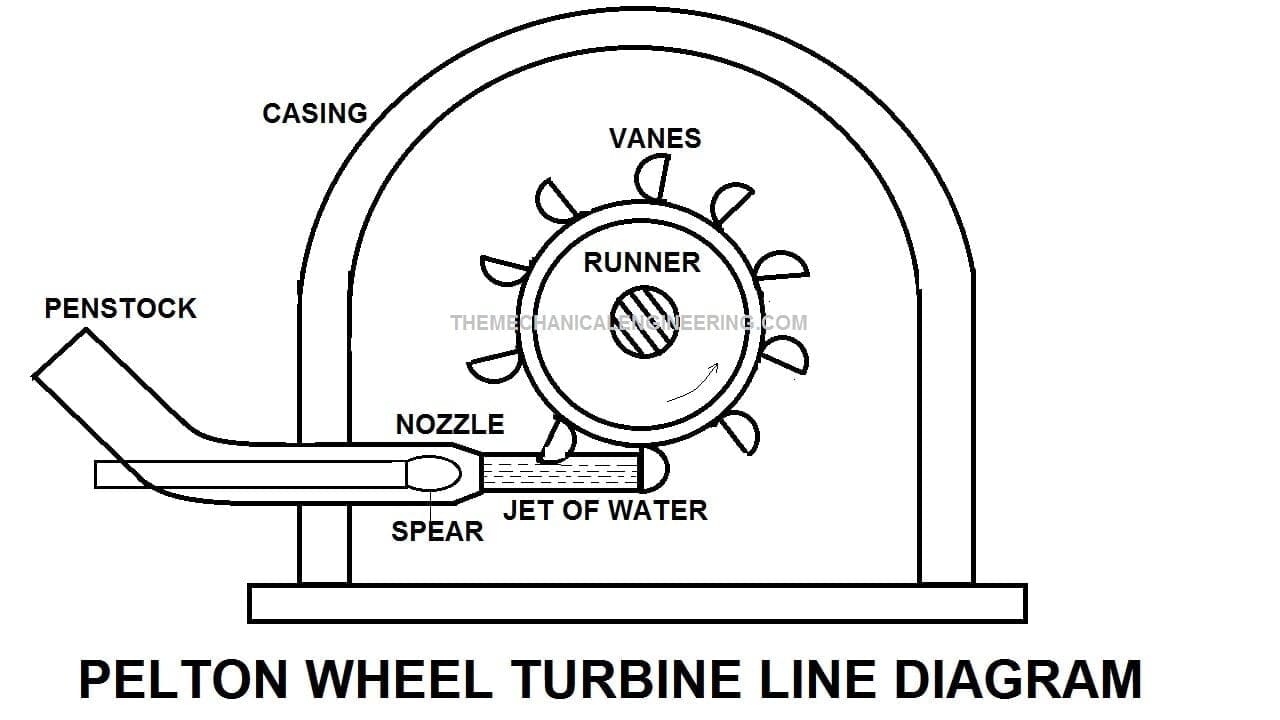

- Impulse Turbine

- Reaction Turbine

- Difference Between Impulse Turbine and Reaction Turbine

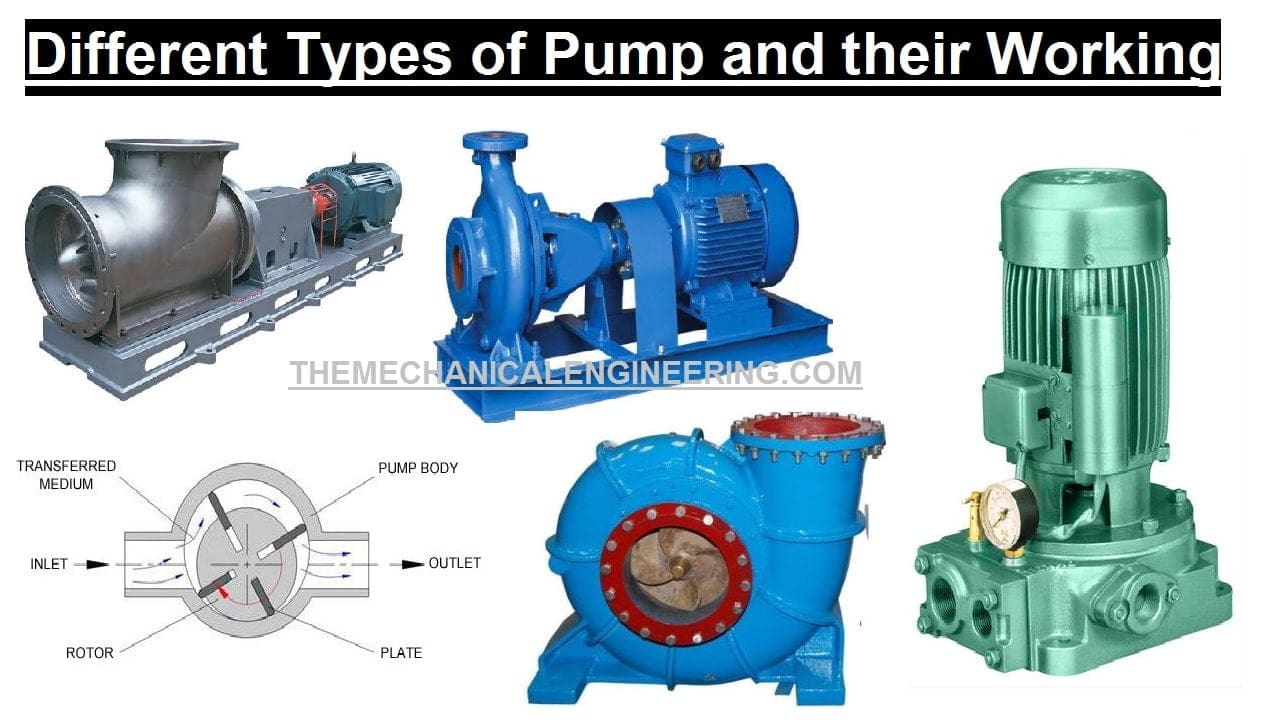

- What is a Pump? What are the different types of Pump and their Working?

- Rotary vs Reciprocating Compressor

- Difference Between Reciprocating Pump and Centrifugal Pump

Reference [External Links]:

- https://koyapete.weebly.com/uploads/1/3/6/4/13645543/fluid_mech_lec._6.pdf

- https://en.wikipedia.org/wiki/Pressure_measurement

- https://byjus.com/physics/manometer/

Conclusion:

Here we finally studied the Manometer and Types in detail. I hope you have understood this topic in detail. If yes then do not forget to share with your friends and family.

I have also explained the different topics of Fluid mechanics and machinery. If you want to read you can go through the URL attached above or you can search.

![Pneumatic System: Definition, Components, Working, Advantages [Notes & PDF] Feature Image of Pneumatic System](https://themechanicalengineering.com/wp-content/uploads/2022/07/Feature-Image-of-Pneumatic-System-300x155.jpg)

![What is Pulley? Different Types of Pulley [Notes & PDF] Feature Image of Pulley](https://themechanicalengineering.com/wp-content/uploads/2022/07/Feature-Image-of-Pulley-300x267.jpg)

![Aluminum: Introduction, Characteristics, Different Types, Application [Notes & PDF] Feature Image of Aluminum Types](https://themechanicalengineering.com/wp-content/uploads/2022/10/Feature-Image-of-Aluminum-300x150.jpg)

![What are the Different Types of Car Lights & Headlights? [Notes & PDF] Feature Image of car Headlight](https://themechanicalengineering.com/wp-content/uploads/2022/10/Feature-Image-of-car-Headlight-300x192.jpg)

![Different Types of Measuring Tools and their Uses [Notes & PDF] Feature Image of Types of Measuring Tools](https://themechanicalengineering.com/wp-content/uploads/2023/01/Feature-Image-of-Types-of-Measuring-Tools-300x171.jpg)

![Steel: Properties, Different Types and Applications [Notes & PDF] Feature Image of Steel](https://themechanicalengineering.com/wp-content/uploads/2023/01/Feature-Image-of-Steel-300x168.jpg)

Discussion about this post