In the previous article, we have studied the Orifice meter that is used to measure the discharge. The same work is done by Venturimeter also.

In this article, we will look at how the venturi meter is different from the orifice and its construction, Working, Derivation, Formula, and last Advantages, Disadvantages, Application.

Note: you can download PDF version at the end of the article.

Venturi Meter Definition:

Venturimeter is a flow meter device or instrument that is used to measure the flow rate (discharge) in a pipe. The venturi meter is used in the water supply industry and It works on the basis of the Bernoulli theorem. The venturi meter is invented by Clemans Herchel who was an American Hydraulic engineer.

Now we will look different types of it,

Venturi Meter or Plate Types:

There are four different types of venturi tubes and those are:

- Classic venturi tube or A standard long-form.

- A modified short form where the outlet cone is shortened.

- An eccentric form to handle mixed phases or to minimize the build-up of heavy materials.

- A rectangular form used in the ductwork.

Venturi Meter Construction or Parts:

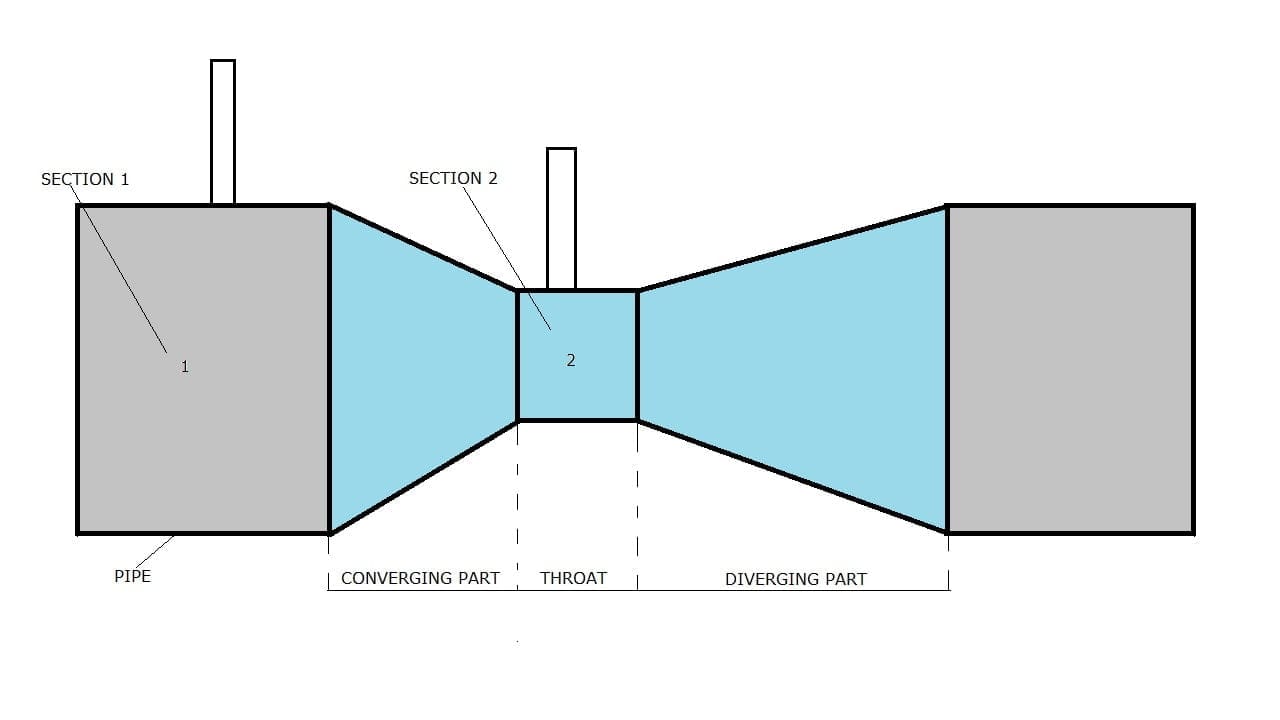

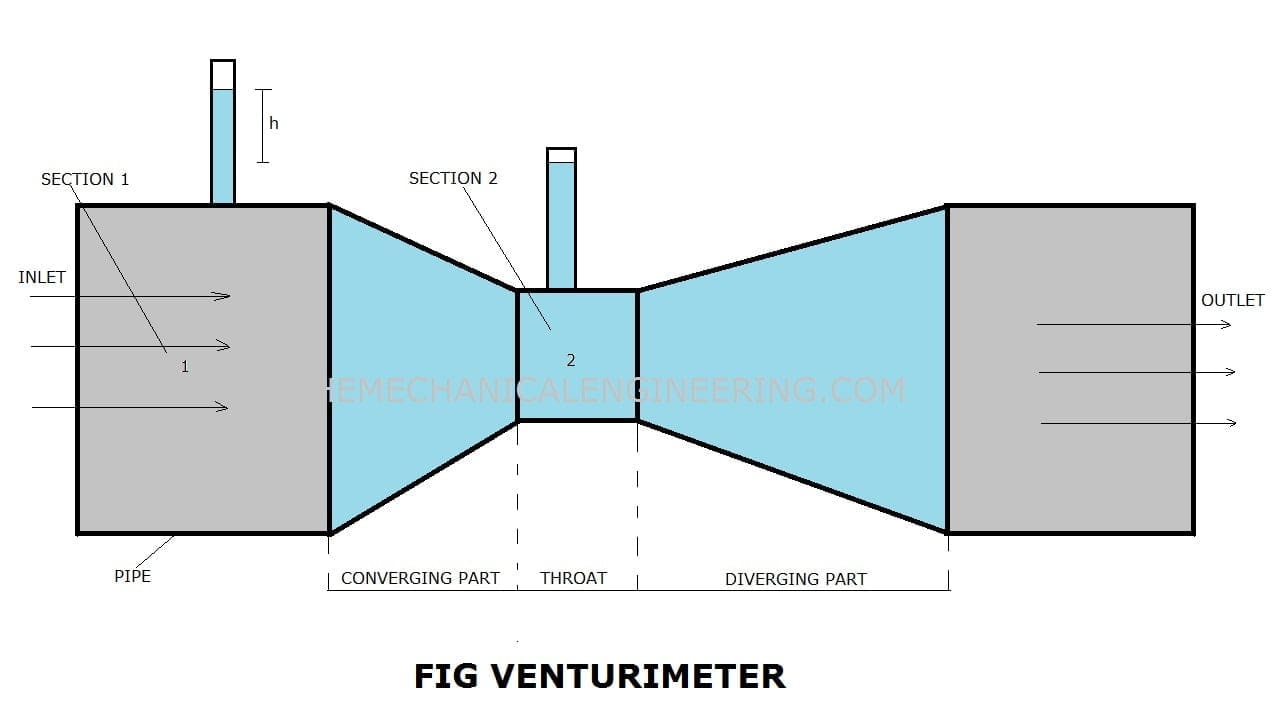

Venturi meter has been divided into three parts such as:

- Converging Part

- Throat Diameter and

- Diverging Side

Converging Part:

First, the water is flowing through the pipe then The water is enetered into converging parts. In this the cross sectional area is decresing.

Throat Diameter:

The throat diameter is an in-between converging and diverging parts. The cross-sectional area of the throat is smaller than the converging and diverging parts. Here the velocity is increases and pressure decreases.

Diverging Side:

In this part, the water is moving outside from the diverging side and again it flows to the pipe. The cross-sectional area is increasing here so the pressure starts increasing.

Venturi Meter Working Principle:

The venturi meter is placed in a pipe carrying the fluid. To measure the flow rate that is discharged, a pressure drop occurs between the entrance and throat of the venturi meter.

With the use of differential pressure, we use the pressure drop, and when the pressure drop is calibrated then that produces flow rate (Discharge) measurement.

Lets study in depth:

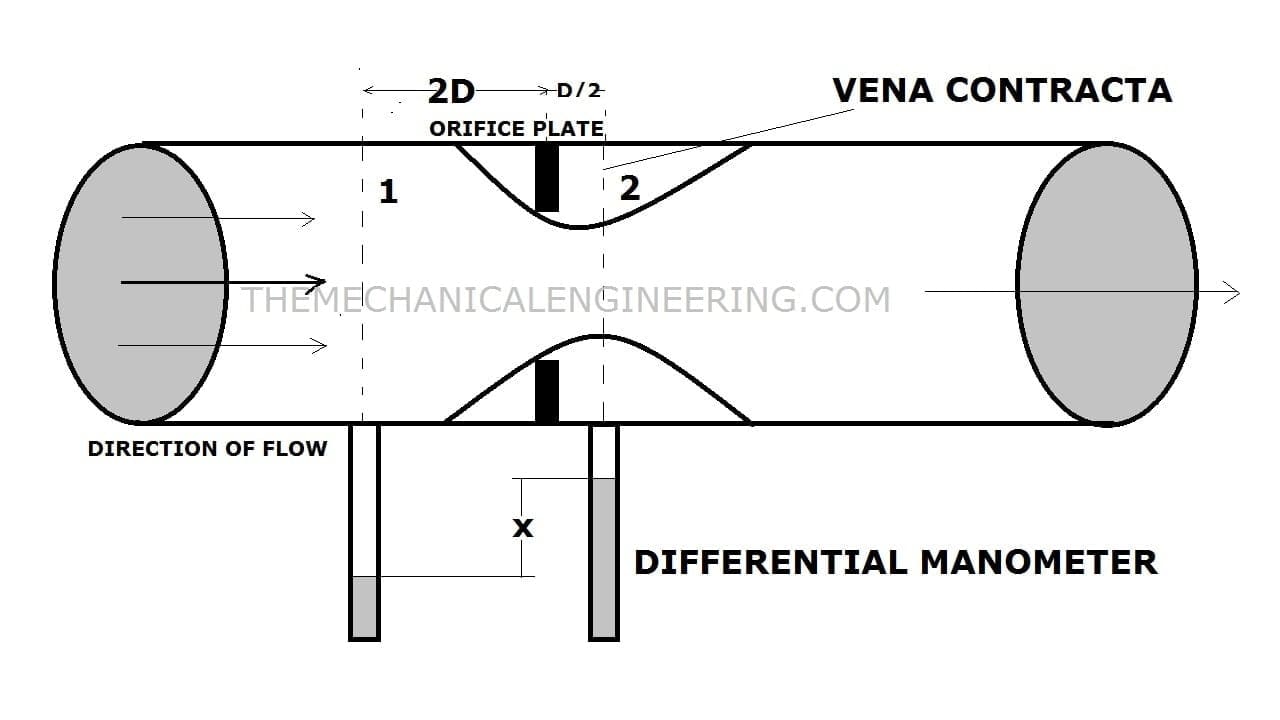

From the diagram you can see the water is first enetd into the converging part with pressure p1 whose discharge or flow rate to be measure.

Now here the cross-sectional area is decreasing the pressure decreases and velocity increases and now it entered into at throat section.

Till now the pressure is decreasing and here it is a minimum. The pressure measuring instrument is attached between converging parts and the throat part to record the pressure difference.

Now with the help of a pressure difference, we can easily calculate the discharge of fluid (By using some equation which will be discussed below).

And now the fluid will move into the diverging section here the cross-sectional area is increasing, therefore, the pressure will start increasing.

Now moving to our main topic derivation of venturimeter,

Venturi Meter Derivation or Experiment:

Lets consider a horizotal pipe in that the venturimeter is fitted and the water is flowing as you can see in the diagram.

The p1, v1, d1, and a1 are the corresponding pressure, velocity, diameter, and area in section 1, and

The p2, v2, d2, and a2 are the corresponding pressure, velocity, diameter, and area in section 2.

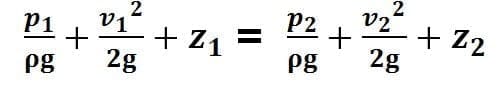

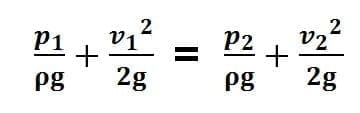

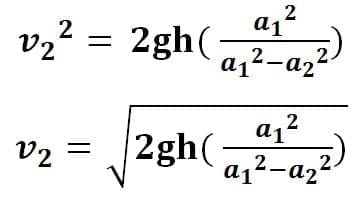

Now applying Bernoulis equation in both the section one and two,

The z1 and z2 will be eliminated because both having same distance from ground.

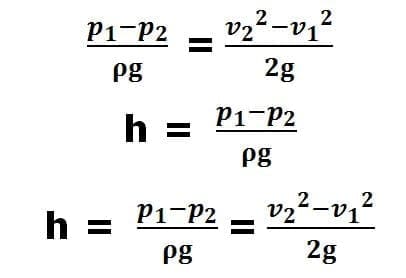

The pressure head difference (p1-p2)/ρg is equal to h.

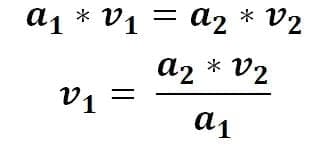

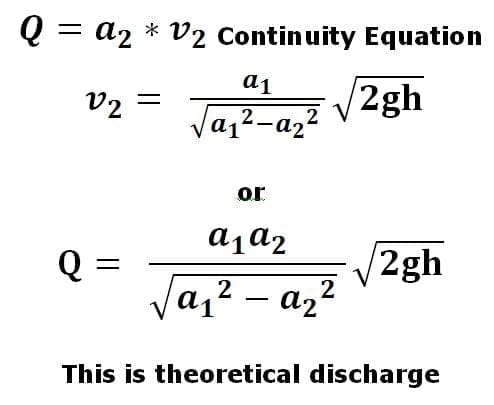

Now applying continuity equation,

The continuity equation is the product of the cross-sectional area and velocity. I.E (Q= a * v)

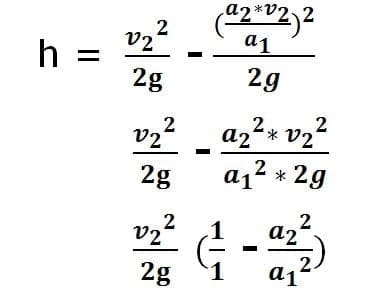

Now putting value of h which we found in the above equation in v1,

After cross multiplying, Now we can write above equation,

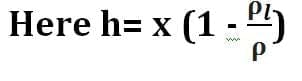

- Here x is the difference between the liquid column in U tube,

- ρL = density of the lighter liquid and

- ρ = density of liquid flowing through the pipe.

Now,

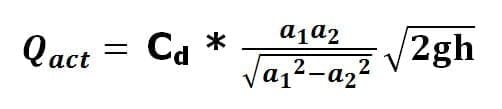

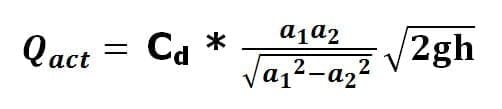

Actual Discharge: (Actual Discharge is the product of the coefficient of discharge and theoretical discharge).

So here we finally made the derivation of venturimeter.

Venturi Meter Formula:

To find the Coefficient of discharge then we have to divide actual discharge by the theoretical discharge.

If we want to find actual discharge then we will multiply the coefficient of discharge into the theoretical discharge.

Venturi Meter Specification:

The following specification of Venturimeter:

- The Line Size of the venturi meter ranges from 100 mm to 800 mm.

- The accuracy can vary from +/-0.25% to +/-3.0%.

- Flow coefficient value: 0.98 for all ratios of diameter

- Beta ratios (It can be defined as the ratio of the throat diameter to the main pipe diameter): 0.3 and 0.75.

Venturi Meter Advantages:

There are following advantages of venturi meter and that is:

- The venturi meter is very much accurate than the other flow meter like an orifice.

- Here the coefficient of discharge is high.

- The installation of direction can be vertical, horizontal or it can be inclined also.

- This meter also used for dust water too that is a major advantage.

Venturi Meter Disadvantages:

The following disadvantages of Venturi meter:

- The venturi meter size is large compare to the orifice meter and due to this, it can not fit where space is limited.

- It requires a large space as the size is more.

- The installation cost is high as compare to other types of flow meter.

- The maintenance cost is more and

- Compare to orifice the maintenance is a little difficult here.

- It has less experimental data compared to the orifice meter.

- Venturi meter has a limitation and that is Its low Reynolds number of 150,000.

- There is a limitation that the diameter which is around 80mm or less than 80 mm can not use venturi meter.

Venturimeter Application:

The following application of Venturi meter is:

- The venturi meter is a flow meter that used where high-pressure recovery is required.

- Used in the Medical industry like measuring the flow rate of blood in arteries.

- It can also be used for measuring flow rates (Discharge) at several places such as gases, water, suspended solids, slurries, and dirty liquids.

Finally, the articles end here. If you have any doubt feel free to ask in the comment box and if you like the article then do not forget to share on social platforms.

Reference [External Links]:

- Virtual Labs Derivation of Venturimeter

- Instrumentation Tool Animation Venturimeter

![Pneumatic System: Definition, Components, Working, Advantages [Notes & PDF] Feature Image of Pneumatic System](https://themechanicalengineering.com/wp-content/uploads/2022/07/Feature-Image-of-Pneumatic-System-300x155.jpg)

![Aluminum: Introduction, Characteristics, Different Types, Application [Notes & PDF] Feature Image of Aluminum Types](https://themechanicalengineering.com/wp-content/uploads/2022/10/Feature-Image-of-Aluminum-300x150.jpg)

![What is Pulley? Different Types of Pulley [Notes & PDF] Feature Image of Pulley](https://themechanicalengineering.com/wp-content/uploads/2022/07/Feature-Image-of-Pulley-300x267.jpg)

![What are the Different Types of Car Lights & Headlights? [Notes & PDF] Feature Image of car Headlight](https://themechanicalengineering.com/wp-content/uploads/2022/10/Feature-Image-of-car-Headlight-300x192.jpg)

![Different Types of Measuring Tools and their Uses [Notes & PDF] Feature Image of Types of Measuring Tools](https://themechanicalengineering.com/wp-content/uploads/2023/01/Feature-Image-of-Types-of-Measuring-Tools-300x171.jpg)

![Steel: Properties, Different Types and Applications [Notes & PDF] Feature Image of Steel](https://themechanicalengineering.com/wp-content/uploads/2023/01/Feature-Image-of-Steel-300x168.jpg)

Discussion about this post