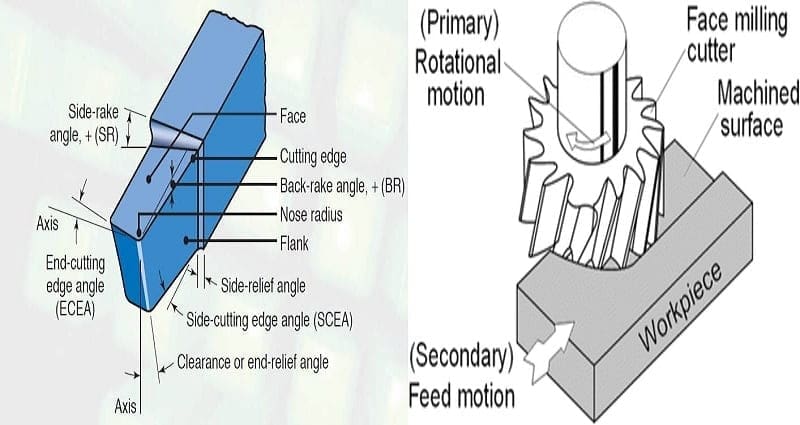

The main difference between the Single and Multi-Point Cutting tool is the Single Point cutting tool contains Only one main cutting edge and the Multi-Point Cutting tool contains more than one cutting edge.

In this article, we will study the 15 points of Difference between Single Point Cutting Tool and Multi-point Cutting Tool.

Note: At the end of the article you can download PDF.

Let’s start,

Difference Between Single Point Cutting Tool and Multi-point Cutting Tool:

| Sl No. | Single Point Cutting Tool | Multi-Point Cutting Tool |

| 1. | While manufacturing if a tool is broken out then the entire process is required to pause until the broken tool is replaced by a new one tool. | In this, if one edge broke out, cutting action can be continued using other cutting edges without much problem. |

| 2. | This cutting tool contains Only one main cutting edge | Here it is having more than 1 cutting edges. |

| 3. | While performing an operation the tool contact with the workpiece so that only one cutting tool edges contacts but whereas | In Multi-point cutting tool contacts more than one. |

| 4. | The operation we perform from this tool is: Turning, facing, Making a flat surface. | But here he performs an operation like Gear cutting, broach, Knurling and more. |

| 5. | Single Point cutting tools used in machines like Shaper, Planer, Lathe, or Slotter machines. | Multi-Point cutting tool uses in the machine-like Milling, Grinding or More. |

| 6. | Design and fabrication are simple. | Design and fabrication are difficult. |

| 7. | The entire chip load in a single pass is borne by only one cutting edge. | Complete chip load in a single pass is distributed among all cutting edges. |

| 8. | In terms of accuracy, this one provides a good surface finish. | But a Multi-point cutting tool provides greater surface finish. |

| 9. | Single point cutting tool can be made from grinding machine. | Multi-point cutting tools can not manufacture from only grinder machines. |

| 10. | While manufacturing single point toll time taking is less. | In this, it takes more time to manufacture. |

| 11. | Single point cutting is a Low-cost tool. | Multi-point cutting is a High-cost tool. |

| 12. | Cutting temperature is High | Compare to the single-point cutting tool the cutting temperature is low. |

| 13. | Tool life of single point is a shorter comparatively multi-point cutting tool. | Its tool life is more. |

| 14. | Low material removal rate. | Good or More material removal rate compared o a single-point cutting tool. |

| 15. | The tool wear rate is high. | The tool wear rate is low. |

So here we studied 15 points on differences between single and multi-point cutting tools. Let me know if you understand or not?

If yes then please share these articles with your social group to help others.

Other Resources:

Single Point Cutting Tool

Injection Molding

Types of Gear

UP Milling vs Down Milling

Here you can read all the articles of Manufacturing Technology.

Here The PDF of this article is attached and you can download it easily by just clicking the download PDF button.

![Different Types of Measuring Tools and their Uses [Notes & PDF] Feature Image of Types of Measuring Tools](https://themechanicalengineering.com/wp-content/uploads/2023/01/Feature-Image-of-Types-of-Measuring-Tools-300x171.jpg)

![Steel: Properties, Different Types and Applications [Notes & PDF] Feature Image of Steel](https://themechanicalengineering.com/wp-content/uploads/2023/01/Feature-Image-of-Steel-300x168.jpg)

![Pneumatic System: Definition, Components, Working, Advantages [Notes & PDF] Feature Image of Pneumatic System](https://themechanicalengineering.com/wp-content/uploads/2022/07/Feature-Image-of-Pneumatic-System-300x155.jpg)

![What is Pulley? Different Types of Pulley [Notes & PDF] Feature Image of Pulley](https://themechanicalengineering.com/wp-content/uploads/2022/07/Feature-Image-of-Pulley-300x267.jpg)

Discussion about this post