The extrusion process is one of the types of bulk-forming processes in which work metal is forced or compressed through a die hole to achieve a certain required cross-sectional shape.

In simple words, extrusion is a metalworking procedure that involves forcing metal through a die hole under increased pressure to compress its cross-section.

Since, the evolution of the extrusion process, the world has become dependent on extrusion to produce bars, tubes, and sections of any shape either hollow or solid.

Because, this operation involves pushing or pulling of billet through the die, the forces necessary to extrude the billet are fairly large. Hot extrusion is the most common method because metal deformation resistance is low at high temperatures, while cold extrusion is generally performed on soft metals only.

History:

Although the concept of extrusion is born from the process of forming. It is recorded that in 1797, an engineer by the name of Joseph Bramah patented the process of extrusion.

The trial involved preheating of metal and then forcing it through a die cavity for making a pipe out of the billet. He used a hand-driven plunger to force the metal.

Bramah then invented the hydraulic process after the invention of Extrusion. Then, Thomas Burr used the technology of hydraulic press and basic extrusion technique combining the individual technologies to produce a pipe (hollow). It was also then patented in the year of 1820.

The technology then became a basic need in the growing world, while the process could not work on the hard metals. In the year 1894, Thomas Burr introduced extrusion with copper and brass alloys which brought an evolution in extrusion technique.

Since the invention of the extrusion technique, the process has evolved into a variety of techniques capable of producing a wide range of products with complex structures at the lowest possible cost.

Classification or Types of Extrusion Process:

Different types of Extrusion Processes:

- Hot extrusion

- Cold extrusion

- Warm extrusion

- Friction extrusion

- Micro extrusion

- Direct extrusion

- Indirect extrusion

- Hydrostatic extrusion and

- Impact extrusion Process.

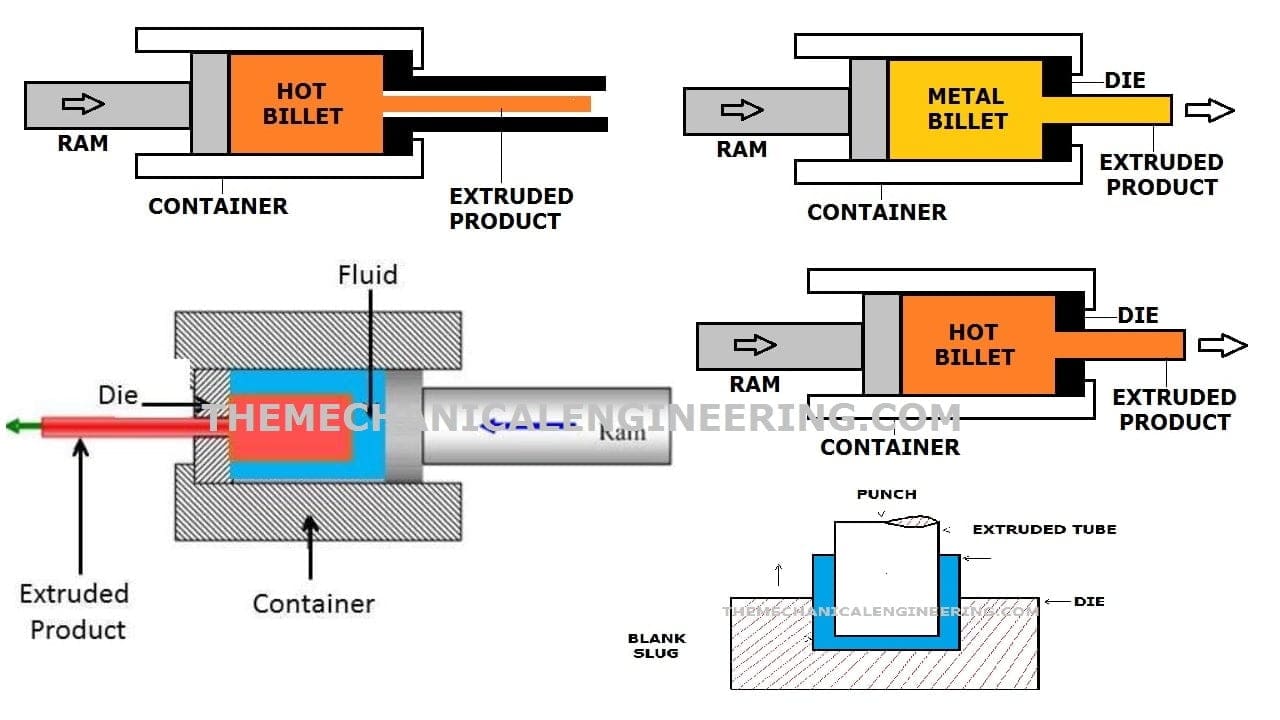

#1. Hot Extrusion Process:

In this Hot extrusion process, the billet is worked above its recrystallization temperature. This hot working allows to keep the workpiece from work hardening and makes the ram push it easily through the die.

Hot extrusions are generally performed on horizontal hydraulic presses. The pressure involved in this process can vary from 30 MPa to 700 MPa. To intact the high pressure, lubrication is employed. Oil or graphite is used as a lubricant in low-temperature extrusions and glass powder is used for high-temperature extrusions.

The billet is supplied a heat between 0.5 Tm to 0.75 Tm to obtain a quality operation.

Hot extrusion temperatures of a few commonly used materials are as listed:

| Material | Temperature (˚C) |

| Aluminum | 350 to 500 |

| Copper | 600 to 1100 |

| Magnesium | 350 to 450 |

| Nickel | 1000 to 1200 |

| Steel | 1200 to 1300 |

| Titanium | 700 to 1200 |

| PVC | 180 |

| Nylon | 290 |

Advantages of Hot extrusion Process:

- Deformation can be controlled as per requirements.

- The billet is not subjected to strengthening due to work hardening.

- Lesser forces are required to press.

- Materials with premature cracks can also be worked.

Disadvantages of Hot extrusion Process:

- Poor surface finish.

- Dimensional accuracy is compromisable.

- Lower container life.

- Possibility of surface oxidation.

#2. Cold Extrusion:

It is the process of shaping metal by striking it with a slug. This striking is accomplished with a punch or ram in a closed cavity. The ram forces the metal through the die cavity to transform the solid billet into a solid shape.

In this process, the workpiece is subjected to deformation at room temperature or slightly above room temperature.

For the forces required to be too high, a powerful hydraulic press is used in this technique. The pressure ranges up to 3000 MPa.

Advantages:

- No oxidation.

- Improved strength of the product.

- Closer tolerances.

- Improved surface finish.

- Hardness is improved.

Disadvantages:

- Higher forces are required.

- More power is required to operate.

- Non-ductile materials cannot be worked.

- Strain hardening of the material being extruded is a limitation.

#3. Warm extrusion Process:

Warm extrusion is the process of extruding a billet above room temperature and below the recrystallization temperature of the material. This process is used where the material has to be prevented from microstructural changes that occur during the extrusion process.

This process is important to achieve the proper balance of required forces and ductility. The temperature of any metal used in this operation can be between 424 degrees Celsius to 975 degrees Celsius.

Advantages of Warm Process:

- Improved strength.

- It improved the hardness of the product.

- Lack of oxidation.

- Very close tolerances can be achieved.

Disadvantages:

- Non-ductile materials cannot be extruded.

- A piece of heating equipment is additional.

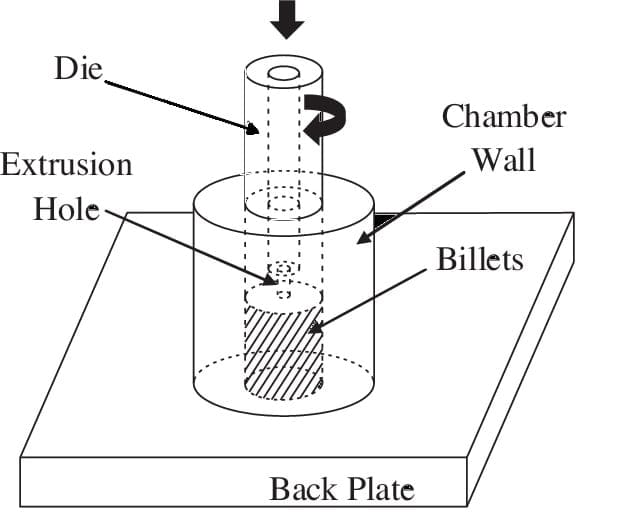

#4. Friction extrusion:

In the friction extrusion technique, the billet and the container are forced to rotate in counter to one another while at work simultaneously the billet is pushed through the die cavity to produce the desired material.

The process is influenced by the relative rotating velocity between the billet and the die. The relative rotating motion of the charge and the die has a significant implication on the process.

First, it results in the generation of a large number of shear stresses causing the billet to deform plastically. Second, a large amount of heat is generated during the relative motion between the billet and the die, thus, no preheating is required making the process more efficient.

It can generate substantially consolidated wire, rods, tubes, and other non-circular metal geometries directly from a variety of precursor charges, such as metal powder, flake, machining waste (chips or swarf), or solid billet.

Advantages of friction Process:

- No heating is required.

- Generation of shear stresses results in improved fatigue strength of the product.

- Any type of material can be used as a billet, thus making this process economical.

- Low energy input.

- Better resistance to corrosion.

Disadvantages of friction Process:

- Expected oxidation.

- High initial setup.

- Complex machinery.

#5. Micro extrusion Process:

It is understood by its nomenclature that this process deals with the production of submillimeter range products.

Similar to macro-level extrusion, the billet here is forced through the die orifice to generate the expected shape on the billet. The output can fit through a 1mm square.

Forward or direct and backward or indirect microextrusion are the two most fundamental techniques being used in this era to produce microelements.

Forward microextrusion has the ram which drives the billet forward and the billet traveling in the same direction, whereas backward microextrusion has the ram and billet moving in opposing directions.

Microextrusion is widely used in the production of components for resorbable and implanted medical devices, ranging from bioresorbable stents to controlled drug release systems.

While, in the mechanical field, the application can be widely observed in the manufacturing of tiny gears, tiny pipes, etc.

Advantages of micro Process:

- Very complex cross-sections can be made.

- Tiny elements can be produced.

- Improved geometric tolerances.

Disadvantages:

- Creating a small die and a container to meet our needs is a challenge.

- A skillful worker is needed.

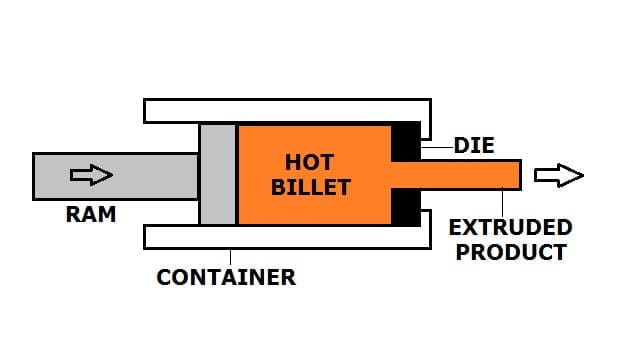

#6. Direct or forward extrusion:

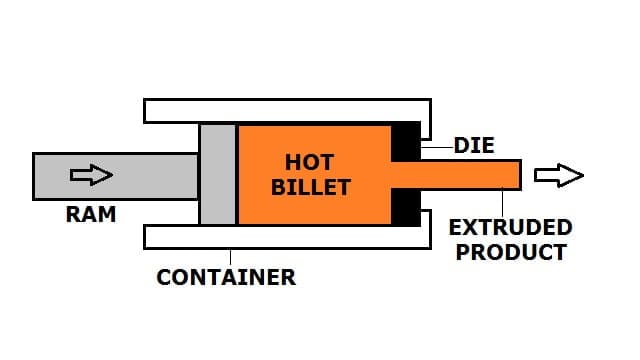

In the direct extrusion process, a metal billet is first placed into the container. The container has a contoured die hole. A ram is utilized to drive the metal billet through the die hole and the product is fabricated.

In this type, the direction of the metal flow is the same as that of the direction of movement of the ram.

As the billet is forced to move toward the die opening, a large amount of friction is produced between the surface of the billet and the container walls. The existence of friction necessitates a significant increase in the ram force thus consuming more power.

In this process, extruding brittle metals such as tungsten and titanium alloys is difficult because they get fractured during the process. The tensile forces throughout the process induce micro-cracks to form quickly, resulting in fractures.

Extruding brittle metals such as Tungsten and Titanium alloys is difficult because they fracture during the process. Tensile forces induce micro-cracks to form quickly, resulting in fractures.

Also, the presence of an oxide layer on the billet’s surface intensifies the friction. This oxide layer has the potential to cause flaws in the extruded product.

In order to overcome this problem, a dummy block is placed between the ram and the work billet to help mitigate the friction.

Tubes, cans, cups, small size gears, shafts, and other extruded goods are examples.

Some parts of the billet always remain at the end of every extrusion. It is called the butt. It is removed from the product by cutting it immediately past the exit of the die.

Advantages of direct Process:

- The process is capable of extruding longer workpieces.

- Improved mechanical properties of the material.

- Good surface finish.

- Cold and hot extrusions are possible.

- Ability to operate continuously.

Disadvantages of direct Process:

- Brittle metals cannot be extruded.

- Large force and high-power requirement.

- Possibility of oxidation.

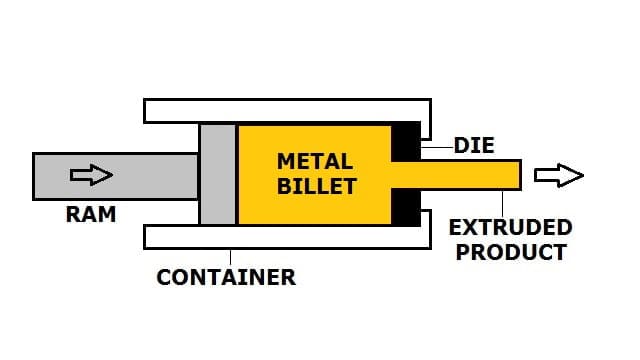

#7. Indirect or backward extrusion:

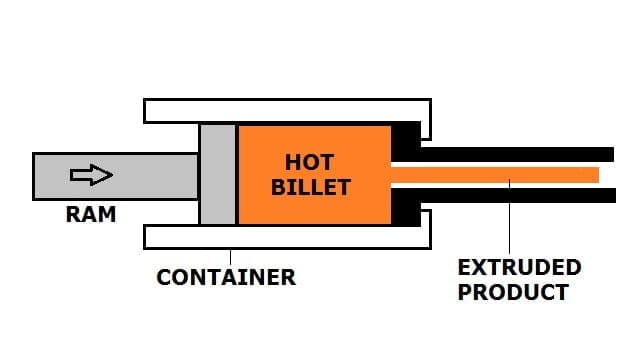

In this backward extrusion process, the die remains stationary, whereas the billet and container move in combination. The die is mounted on the ram rather than the container.

The metal flows through the die hole on the ram side in the opposite direction of the ram’s movement as it is compressed by the ram.

When the billet is compressed, the material will pass between the mandrel and therefore the die opening.

Since there is no relative motion between the billet and the container, no friction is recorded. This lifts up the process over the direct extrusion process causing the ram force used is smaller than in the direct extrusion.

In order to keep the die stationary, a “stem” that is longer than the container’s length is used. The column strength of the stem determines the final and maximum extrusion length.

Because the billet moves in combination with the container, all frictional forces are easily eliminated.

Advantages of indirect Processes:

- Less extrusion force is required.

- Smaller cross-sections can be extruded.

- Reduction of friction by 30%.

- Enhanced operation speed.

- Very little wear is recorded.

- Extrusion faults or coarse-grain ring zones are less likely to arise because the metal flow is more consistent.

Disadvantages of indirect Process.

- Cross-section of the material extruded is confined by the size of the stem employed.

- Possibility of residual stresses past extrusion.

- Impurities and defects affect the surface finish and make the product compromisable.

#8. Hydrostatic extrusion:

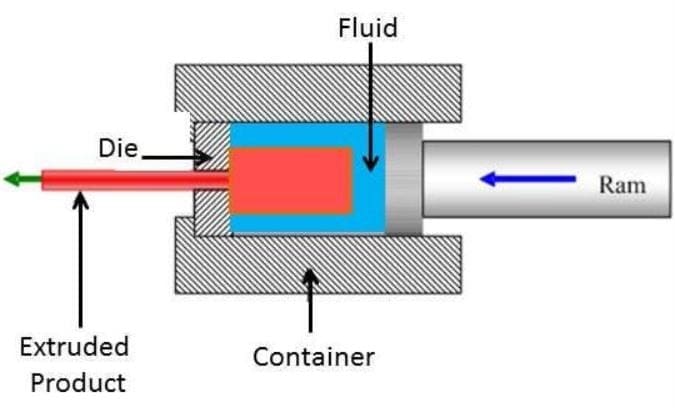

In the hydrostatic extrusion process, the billet is surrounded by fluid within the container, which is pushed against the billet by the forward motion of the ram. There is no friction within the container due to the fluid, and there is very little friction at the die hole.

The billet does not become disturbed when filling the bore of the container since it is subjected to uniform hydrostatic pressure. This successfully results in a billet with a huge length to diameter ratio, even coils of wire can be flawlessly extruded or an uneven cross-section.

The primary difference between hydrostatic and direct extrusions is that there is no direct contact between the container and the billet during hydrostatic extrusion.

Working at high temperatures necessitates the use of specialized fluids and processes.

When a material is subjected to hydrostatic pressure and there is no friction, its ductility increases. As a result, this method might be used on metals that are too brittle for typical extrusion methods.

This approach is used on ductile metals and allows for high reduction ratios.

Advantages:

- Extruded goods have an excellent surface polish and are dimensionally accurate.

- No question of friction.

- Minimized force requirements.

- No billet residue remains in the process.

- The flow of material is even.

Disadvantages:

- When operating at high temperatures, special fluids and procedures should be used.

- Each billet has to be prepared and tapered at one end before work.

- It is difficult to contain the fluid.

#9. Impact extrusion:

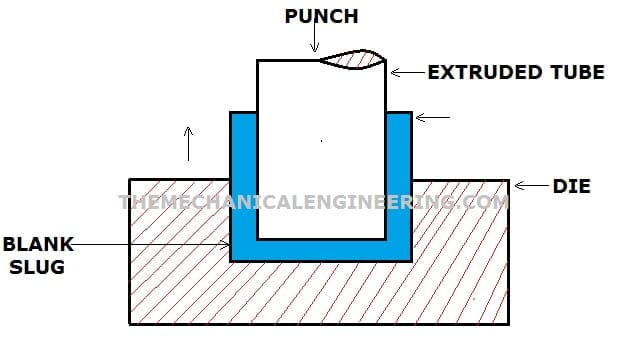

Impact extrusion is another major method for producing metal extruded profiles. In contrast to the traditional extrusion process, which requires high temperatures to soften the material, impact extrusion often uses cold metal billets. These billets are extruded at high pressure and efficiency.

A suitably lubricated slug is placed in a die cavity and hit with a punch in a single stroke during a conventional impact extrusion operation. This causes the metal to flow back around the punch through a gap between the die and the punch.

This process works better with softer materials such as lead, aluminum, or tin.

This process is always performed in a cold state. The backward impact process allows for very thin walls. Make toothpaste tubes or battery boxes, for example.

It is performed at a quicker rate and with shorter strokes. Instead of exerting pressure, impact pressure is employed to extrude the billet through the die. Impacting, on the other hand, can be performed by forwarding or backward extrusion, or a mix of the two.

Advantages:

- Large reduction in size.

- Quick process. Reduced machining time up to 90%.

- Increased production rate.

- Increased tolerance integrity.

- Up to 90% raw material saving.

Disadvantages:

- A very high compressive force is required.

- The size of the billet is a limitation.

Factors affecting the Extrusion force:

The following factors affect the extrusion force are:

- Working temperature.

- Design of the equipment, horizontal or vertical.

- Type of extrusion.

- The ratio of extrusion.

- Quantity of deformation.

- Frictional parameters.

Extrusion Process Application or uses:

- It is widely used in the production of tubes and hollow pipes. And is also used to produce plastic objects.

- The extrusion process is used to produce frames, doors, windows,, etc. in automotive industries.

- The metal Aluminum is used in structure work in many industries.

Internal Resources for You:

- Forging vs Casting

- Hot Working Process

- Cold Working Process

- Forging Tools and their Uses

- Centrifugal Casting

- Buffing and Polishing Process

- Grinding Machine

- Lathe Machine

- Milling Machine

- Drilling Machine

- Planer Machine

- Slotter Machine

Reference [External Links]:

- https://en.wikipedia.org/wiki/Extrusion

- https://uomustansiriyah.edu.iq/media/lectures/5/5_2016_04_18!11_56_29_AM.pdf

- https://www.kmutt.ac.th/p-prof/Teaching%20documents/MTT%20655/MTT655%20W2_Extrusion.pdf

- https://www.me.iitb.ac.in/~ramesh/courses/ME649/extrusion.pdf

Conclusion:

So here we finally studied Extrusion processes in detail. I hope you have understood this topic in detail. I have also explained the different topics of Manufacturing Technology. You can check those articles too.

![Steel: Properties, Different Types and Applications [Notes & PDF] Feature Image of Steel](https://themechanicalengineering.com/wp-content/uploads/2023/01/Feature-Image-of-Steel-300x168.jpg)

Discussion about this post