In this article, we will study What is Laser Beam Machining? and its sub-topics like Definition, Parts or Construction, Working Principle, Advantages, Disadvantages, and Application in detail.

And most important you can download the whole document in PDF format at the end of the articles.

LASER: It stands for Light Amplification Stimulated Emission of Radiation.

The different types of Laser are Solid-state, Gas, and Semiconductor. At high power lasers required for machining and welding, solid-state lasers are used.

We will study in-depth. Let’s start with the definition first,

Laser Beam Machining Definition:

Laser Beam Machining is a non-conventional machining process in which the workpiece is being holed by the laser machining process. To remove the material from the workpiece the process used thermal energy.

Now we are moving to construction or Main Parts, So

Laser Beam Machining Parts or Construction:

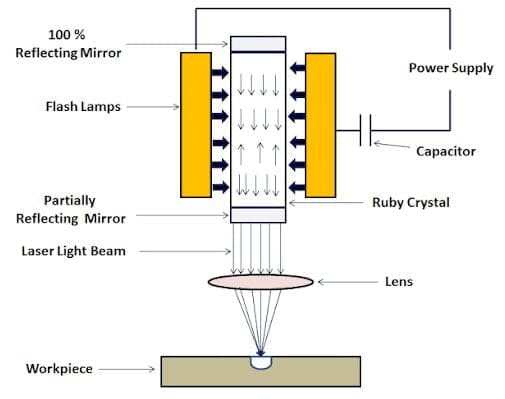

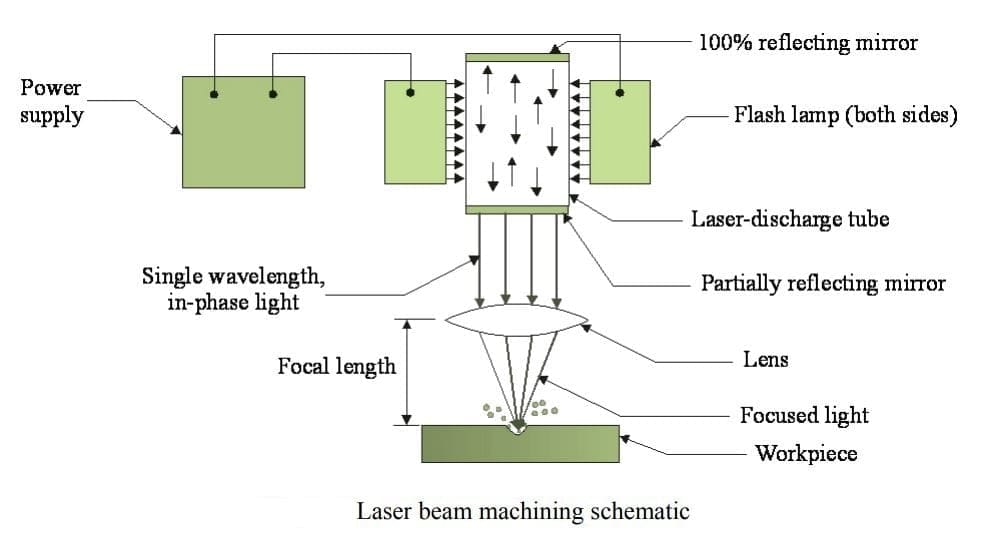

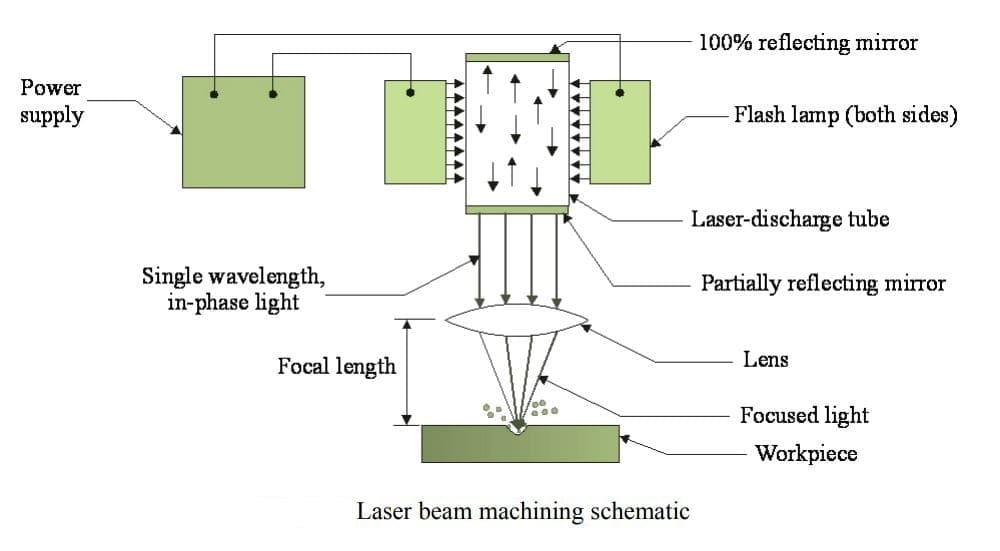

Laser Machining consists of the following Main Parts:

- Power Supply

- Capacitor

- Flash Lamps

- Reflecting Mirror

- Laser Light Beam

- Ruby Crystal

- Lens

- Workpiece

Power Supply:

The electric current or power is supplied to the system. A high voltage power system is used in laser beam machining. It will give initial power to the system after that reaction starts in a laser that will machine the material. There is a high voltage supply so that pulses can be initiated easily

Capacitor:

During the major portion of the cycle, a capacitor bank charges and releases the energy during the flashing process. The capacitor is used for the pulsed mode for charging and discharging.

Flash Lamps:

It is the electric arc lamp that is used to produce extremely intense production of white light which is a coherent high-intensity beam. It is filled with gases that ionize to form great energy that will melt and vaporizes the material of the workpiece.

Reflecting Mirror:

Reflecting Mirror are two main types of internal and external. Internal mirrors also called a resonator that is used to generate maintain and amplify the laser beam. It is used to direct the laser beam towards the workpiece.

Laser Light Beam:

It is the beam of radiation produced by the laser through the process of optical amplification based on the coherence of light created by the bombarding of active material.

Ruby Crystal:

Ruby laser produces a series of coherent pulses which is deep red in color. It achieves by the concept of population inversion. It is a three-level solid-state laser.

Lens:

Lenses are used to focus the laser beam onto the workpiece. First laser light will enter into the expanding lens and then into the collimating lens which makes the light rays parallel and the expanding lens expands the laser beams to the desired size.

Workpiece:

The workpiece can be metallic or non-metallic. In this machining process, any material can be machined.

Laser Beam Machining Working Principle:

Laser Machining is based on the LASER and conversion or process of Electric Energy into Light Energy and into Thermal Energy.

Negatively charged electrons in the atomic model rotate around the positively charged nucleus in orbital paths. It depends on the number of electrons, electron structure, neighboring atoms, and the electromagnetic field.

Every orbital of electrons is associated with different energy levels. An atom is considered to be at ground level at absolute zero temperature at this, all electrons occupy their lowest potential energy.

The electrons at the ground state move to a higher state of energy by absorbing energy like an increase in electronic vibration at elevated temperatures.

High voltage is applied at the ends that leads to discharge and gas plasma will be formed. Population inversion and lasing action will take takes place due to energy transformation.

The laser has one 100% reflector and the other one is a partial reflector. 100% the reflector directs the photons inside the gas tube and the partial reflector allows only some part of the laser beam that will be used for the processing of materials.

The laser beam produced is focused on the workpiece that has to be machined. When the laser strikes the workpiece, the thermal energy impinges on the workpiece.

This will heat then melt, vaporize, and finally, the material will be removed from the workpiece. So laser machining is a thermal material removal process that uses a coherent beam of light to machine the workpiece very precisely.

In the laser machining process, MRR (Material Removal Rate) depends on the wavelength used because it will decide the amount of energy impinged on it.

Laser Beam Machining Working Videos:

Laser Beam Machining Application:

Uses or Applications of Laser Beam Machining are:

- Laser Machining is used for making very small holes, Welding non-conductive and refractory material.

- It is best suited for brittle material with low conductivity and Ceramic, Cloth, and Wood.

- Laser Machining is also used in surgery, micro-drilling operations.

- Spectroscopic Science and Photography in medical science.

- It is also used in mass macro machining production.

- Cutting complex profiles for both thin and hard materials.

- It is used to make tiny holes. Example: Nipples of the baby feeder.

Laser Beam Machining Advantages:

The following advantages of Laser Beam Machining are:

- In Laser Beam Machining any material including non-metal also can be machined.

- Extremely small holes with good accuracy can be machined.

- The tool wear rate is very low.

- There is no mechanical force on the work.

- Soft materials like plastic, rubber can be machined easily.

- It is a very flexible and easily automated machine.

- The heat-affected zone is very small.

- Laser Machining gives a very good surface finish.

- Heat treated and magnetic materials can be welded, without losing their properties.

- The precise location can be ensured on the workpiece.

Laser Beam Machining Disadvantages:

Disadvantages of Laser Beam Machining are:

- Laser Machining cannot be used to produce a blind hole and also not able to drill too deep holes.

- The machined holes are not round and straight.

- The capital and maintenance cost is high.

- There is a problem with safety hazards.

- The overall efficiency of the Laser beam machining is low.

- It is limited to thin sheets.

- The metal-removing rate is also low.

- The flash lamp life is short.

- There is a limited amount of metal removing during the process.

Internal Resources for You:

- Lathe Machine

- Milling Machine

- Photochemical Machining

- Ultrasonic Machining

- Electron Beam Welding

- Electrochemical Machining

- Abrasive Jet Machining

Reference [External Links]:

- https://www.nitc.ac.in/dept/me/jagadeesha/mev303/OVERVIEW_OF_NTM_PROCESSES.pdf

- https://www.me.iitb.ac.in/~ramesh/courses/ME338/non_trad.pdf

- https://www.youtube.com/watch?v=mgaukC25Hqk

This is complete notes of Laser Beam Machining. Let me know if you understood or not. If yes then do not forget to share. Till than Thank you so much. We will meet in another article.

Discussion about this post