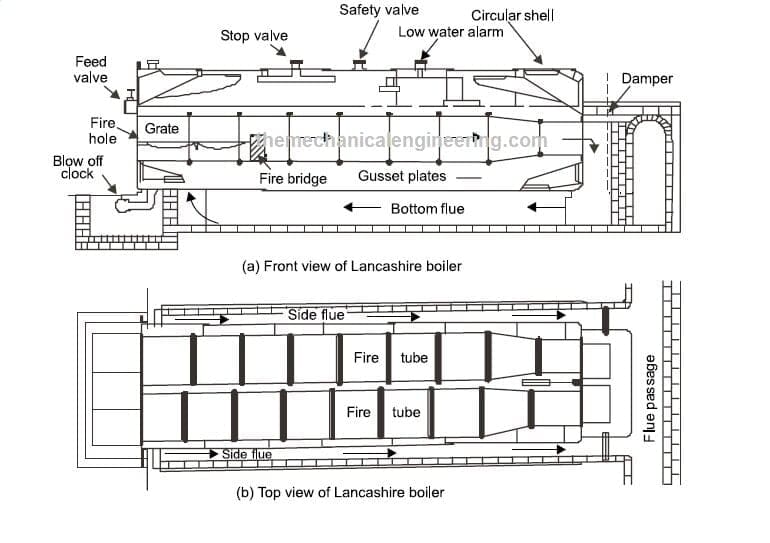

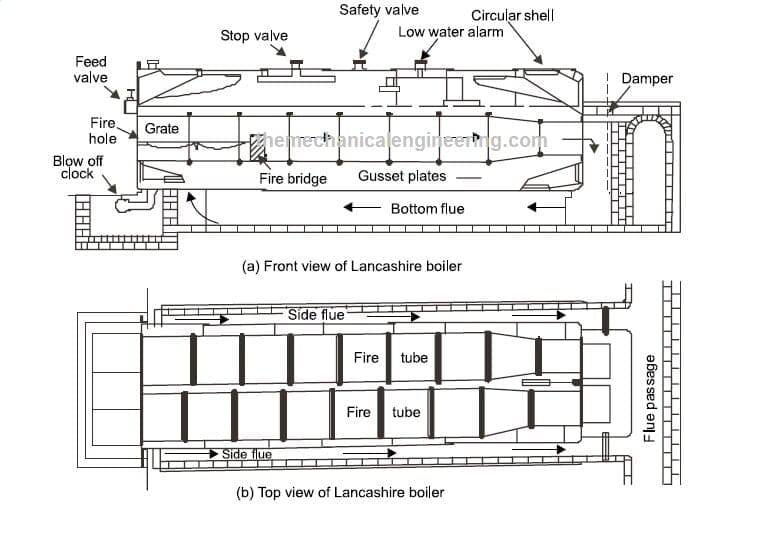

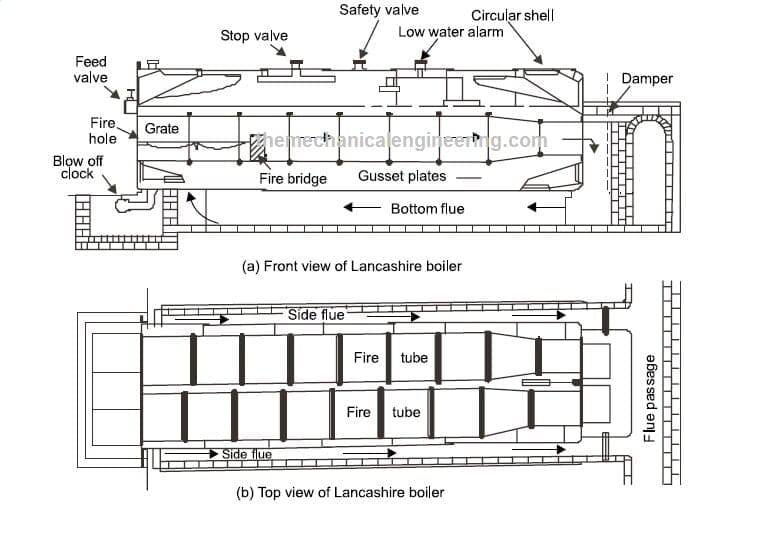

Lancashire Boiler is a fire tube boiler. It was developed in 1844 by Sir William Fairbairn. It is a stationary-type boiler and works on the principle of a Heat exchanger.

In this paper, we will study the definition, Construction, Working principle, Advantages, Disadvantages, and Application of the Lancashire Boiler.

Make sure if you want to download the PDF version then at the end of the article you can download it.

Now we will understand the definition of Lancashire Boiler,

Lancashire Boiler Definition:

Lancashire Boiler is an internal fire tube boiler and similar to the cornish boiler in which the flue gases are in the tube and water is surrounding them. As the temperature is maximum so the water gets converted into steam and that steam is used at several places for different operations. The Lancashire boiler is used in the marine or locomotive industry.

Now come to the construction,

Lancashire Boiler Parts or Construction:

Lancashire Boiler consists of the following Main Parts:

- Shell

- Safety valve

- Pressure Gauge

- Feed check valve

- Water Level Indicator

- Blow off valve

- Steam stop valve

- Manhole

- Fire door

- Fusible Plug

- Ash pit

- Feed pump

- Economizer

- Air preheater

- Superheater

Now let us study one by one in detail,

Shell:

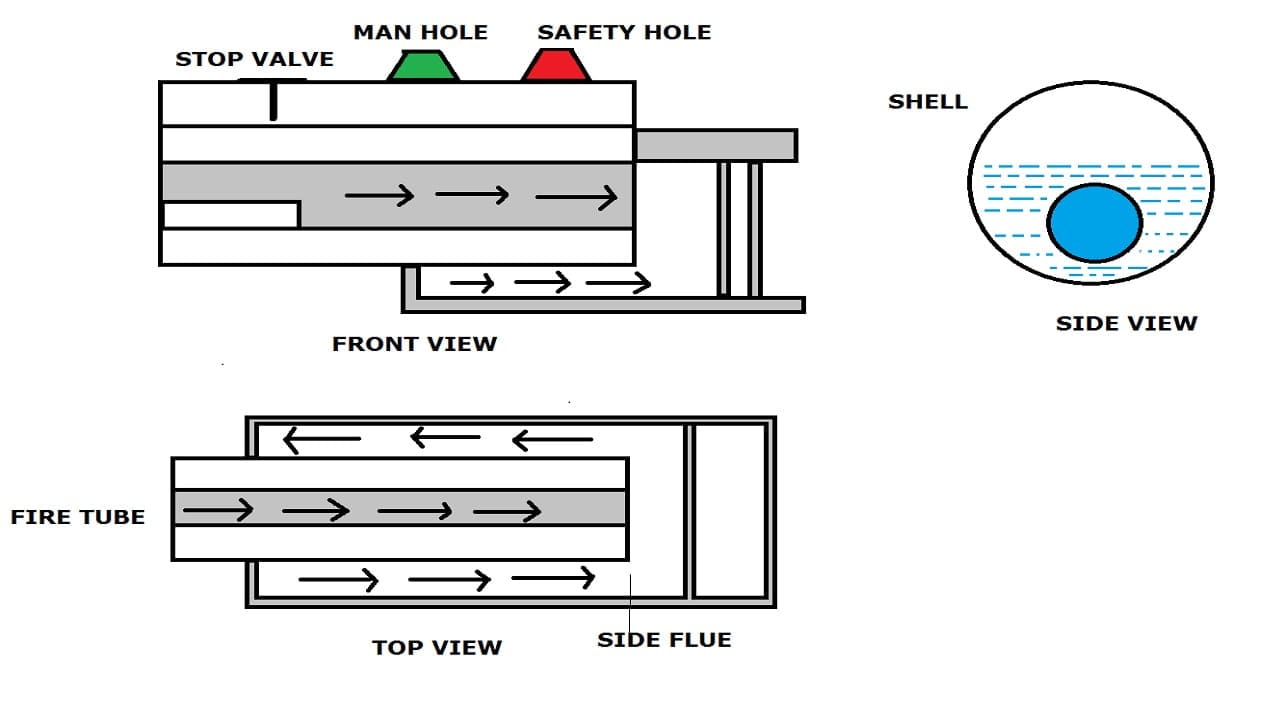

The shape of the shell is cylindrical and it is the outermost part of the Lancashire boiler. The other parts of the Lancashire boiler are present inside the boiler shell.

Safety valve:

Safety Valves prevent from the boiler busting. A safety Valve is used to Blow off the steam when their pressure is exceeded.

Pressure Gauge:

It is a device that is used for getting information related to boiler pressure. When the pressure is maximum and minimum it will indicate the value of pressure inside the boiler.

Water Level Indicator:

It is an important part of the system it helps to regulate the flow of water into the boiler and it checks the level of water in the system when there is less water needed than with the use of a feed pump the water is supplied.

Blow off valve:

The blow-off valve is used to remove the wastes that are sediment or mud which are accumulated at the bottom of the boiler. These muds need to be fixed because they can create problems during operation.

Steam stop valve:

The main function of the steam stop valve is to stop the stream flowing from the boiler to the steam pipe.

Fire door:

At the fire door, the solid fuel is placed and has to ignite for burning to produce flue gases inside the boiler. From the fire door, the solid fuel is ignited.

Feed check valve:

It is like controlling the flow of water into the boiler and also preventing the backflow of the water from the boiler to the pump.

Fusible Plug:

Fusible plug work is similar to a safety valve that helps from bursting.

The fusible valve is used when the safety valve does not work and the boiler pressure exceeds the pressure limit then The steam generated from the boiler goes out of the boiler and prevents it from bursting.

Ash pit:

The fuel is burnt and converted into ashes and that ash comes into the ash pit. The ash pit collects the whole ashes after the solid fuel coal is burnt.

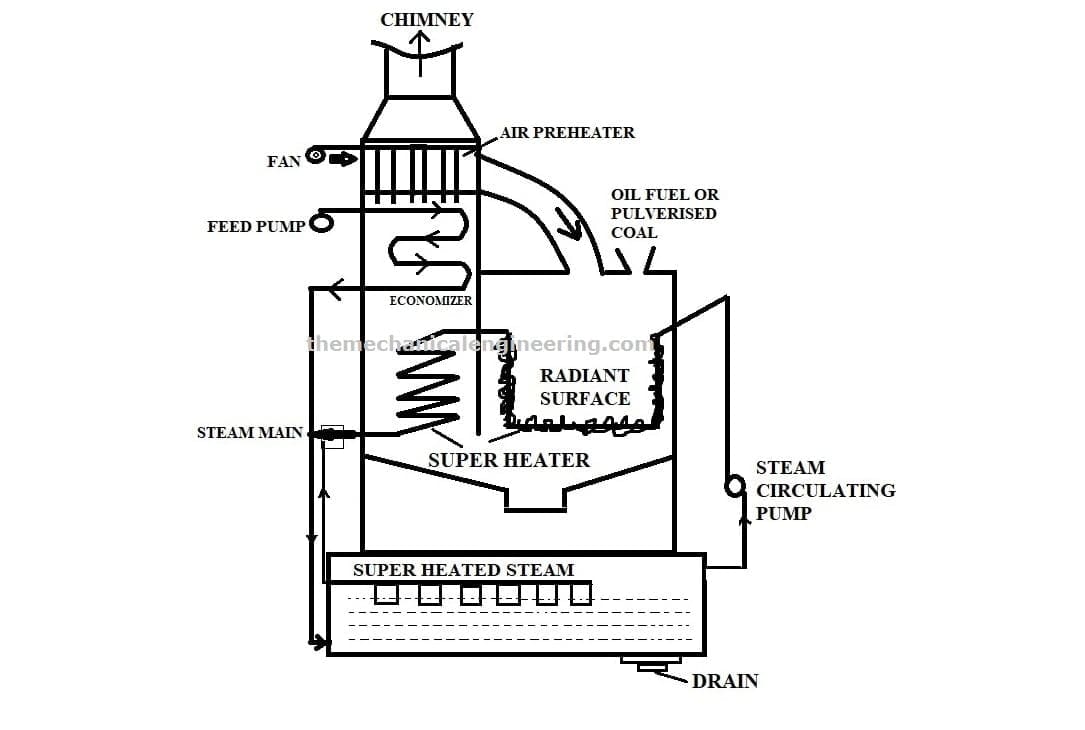

Economizer:

The economizer is an external and mechanical component that is used to increase the efficiency of the boiler.

The work of the economizer is to pre-heat the water by taking the residual heat which is flue gases.

Manhole:

When the boiler gets any problem like wear and tear or any parts is not working or it may be any problem then a Boiler skilled operator is entered the boiler to fix the problem.

Air preheater:

This is similar to an economizer that helps to increase boiler efficiency. It recovers heat in the exhaust gases by heating the air supplied to the furnace.

Superheater:

The superheater is used to superheat the steam that is generated in the boiler. It gets heat from the flue gases. Here the temperature is much higher.

Now working of Lancashire Boiler,

Lancashire Boiler Working Principle:

The Lancashire Boiler works on the principle of Heat Exchanger. A Heat Exchanger is a device that is used for the transfer of heat between two or more fluids.

The solid fuel that is coal is placed at the grate for burning and producing heat. The water is pumped into the system by using a feed pump.

Now supply the heat to the coal to start burning. When it burns it produces flue gases and that flue gas is sent to the fire tube of the boiler.

Here the water is surrounding the tube. The flue gases have maximum temperature and also with the use of a superheater, it increases the temperature.

So that the water starts evaporating and is fully converted into the saturated steam and meanwhile some amount of flue gases is also passing through the bottom and side passage that also helps to heat the water.

The amount of steam generated is controlled by the steam regulating and stop valve. And meanwhile with the use of a water level indicator, will check the water level if the water is required then we have to supply the water.

At the grate, there is an arc in which the burning coal ashes are stored so that they can not mix with the flue gases.

Through the chimney, the waste gases are released into the environment.

Now for better efficiency, we use a device that is an economizer. The economizer helps the water to preheat and then it entered into the system.

Generally, the boiler length is 8 to 9 meters and 2 to 3 meters in boiler diameter. The pressure range is 16 bar. The steam production rate is 9000 kg/hr. Depending on the type of fuel used the efficiency varies.

Lancashire Boiler Video in Hindi:

Features of Lancashire Boiler:

The features of Lancashire Boiler includes:

- Lancashire boiler, overall efficiency is higher than a fire tube boiler.

- The component which is in the boiler can be inspected during the operation also and when there is no operation then we can easily inspect the component.

- If the tubes get infected they can be replaced easily.

- There is a minimum draught loss compared with other boilers.

- To promote the circulation of water the water tube kept at 10 to 10 degrees Celsius.

Lancashire Boiler Advantages:

There are some advantages and those are:

- Lancashire boiler can easily meet the load requirement.

- The cleanliness and inspection are easy in the Lancashire boiler.

- The operation is easy.

- Maintenance is less required.

- It is a natural circulation boiler, therefore, the consumption of electricity is less.

- It has high thermal efficiency of around 90 percent.

Lancashire Boiler Disadvantages:

The disadvantages of Lancashire boiler is:

- More space required for this boiler because the size is big.

- The steam generation is not high like other fire tube boiler.

- The grates area is limited because It is situated at the inlet of the fire tube, which has a small diameter.

- There is having a problem with leakage.

- For a steam generation, it takes much time.

Lancashire Boiler Application:

The following application of Lancashire Boiler is:

- The Lancashire boiler used in industries like sugar mills and tire industries.

- The amount of steam generated from this boiler is used to drive steam turbines, which helps to generate electricity.

- It is also used in the locomotive system and marine engine too.

Internal Resources for You:

- Fire Tube boiler

- Water Tube Boiler

- Difference between Fire Tube and Water Tube Boiler

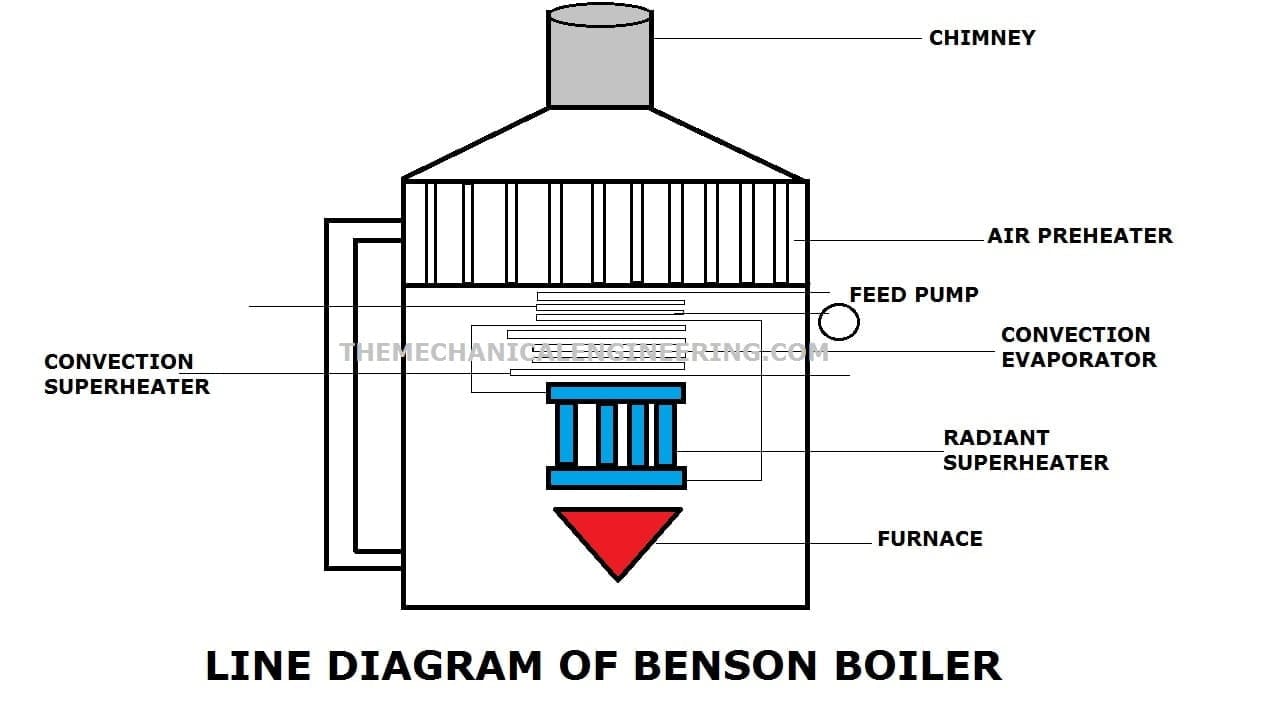

- Benson Boiler

- Locomotive Boiler

- Lamont Boiler

- Cochran Boiler

- Cornish Boiler

Reference [External Links]:

Now we have finally studied Lancashire Boiler in detail. Let me know in the comment box if you have any doubt. If you like the article then please do share it on social media.

![Electrochemical Grinding: Definition, Parts or Construction, Working Principle, Application, Advantages, and Disadvantages [Notes & PDF] FEATURE IMAGE OF ELECTROCHEMICAL GRINDING](https://themechanicalengineering.com/wp-content/uploads/2021/08/FEATURE-IMAGE-OF-ELECTROCHEMICAL-GRINDING-300x169.jpg)

![Electrochemical Deburring: Definition, Parts or Construction, Working Principle, Application, Advantages, and Disadvantages [Notes & PDF] ELectrochemical Deburring](https://themechanicalengineering.com/wp-content/uploads/2021/08/Feature-Image-of-ELectrochemical-Deburring-300x169.png)

![Camshaft: Definition, Function, Construction, Working Principle, Types in detail, Advantages, Application [Notes & PDF] Feature Image of Camshaft](https://themechanicalengineering.com/wp-content/uploads/2021/09/Feature-Image-of-Camshaft-300x169.jpg)

![Flywheel: Definition, Function, Construction, Working Principle, Material, Advantages, Application [Notes & PDF] Feature Image of Flywheel](https://themechanicalengineering.com/wp-content/uploads/2021/09/Feature-Image-of-Flywheel-300x200.jpg)

![Electron Beam Welding: Definition, Working Principle, Construction, Advantages, Application [Notes & PDF] Electron beam welding](https://themechanicalengineering.com/wp-content/uploads/2021/11/Feature-Image-of-Electron-Beam-Welding-300x206.jpg)

![Synchromesh Gearbox: Definition, Construction, Working Principle, Advantages, Application [Notes & PDF] Synchromesh Gearbox](https://themechanicalengineering.com/wp-content/uploads/2022/01/Feature-image-of-Synchromesh-Gearbox-300x173.jpg)

Discussion about this post