What is Cylinder or Engine block in an Automobile?

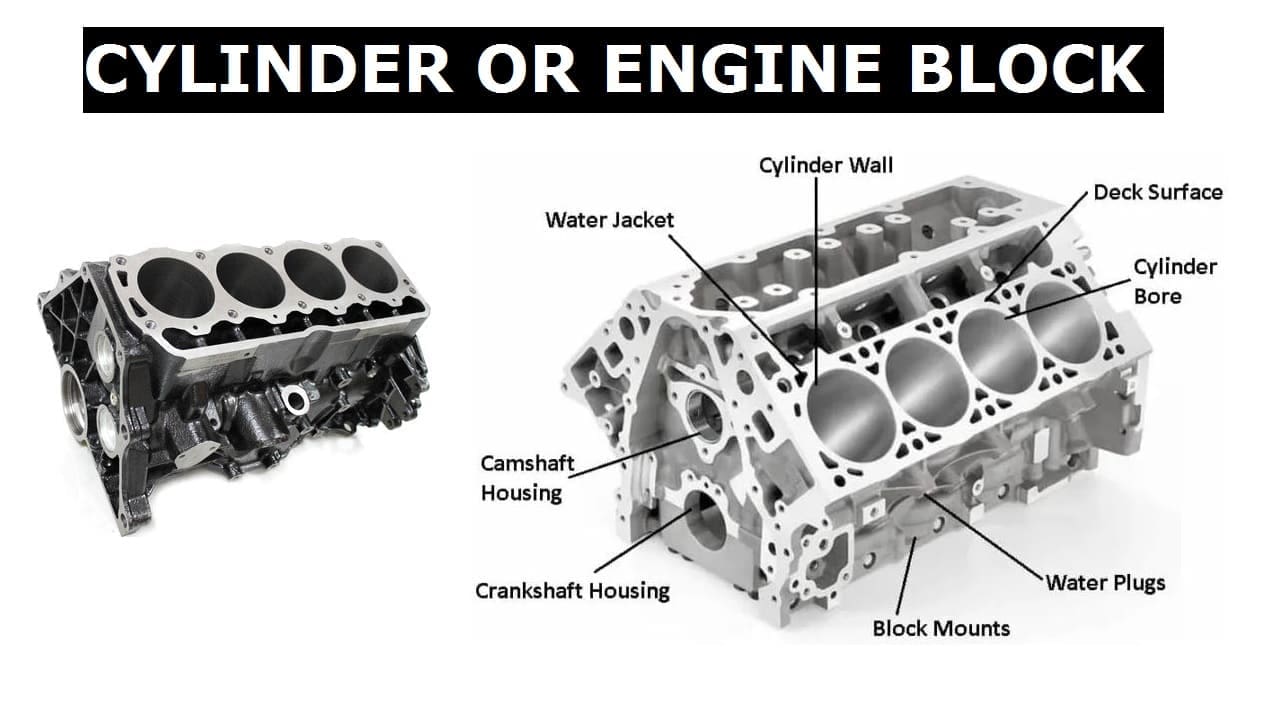

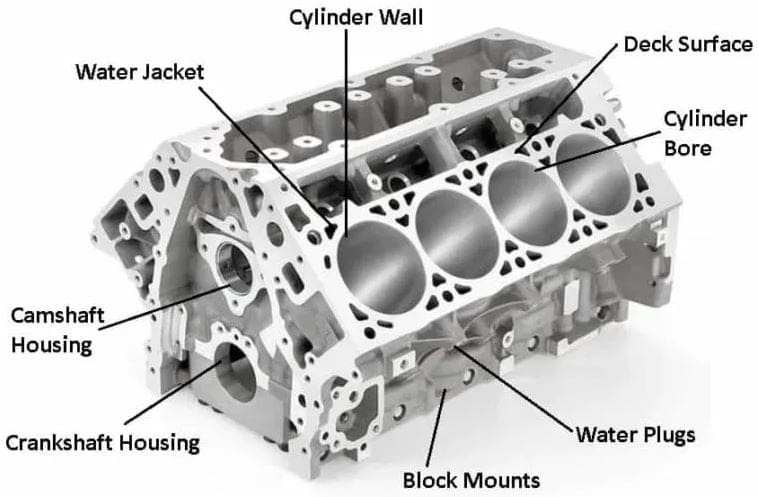

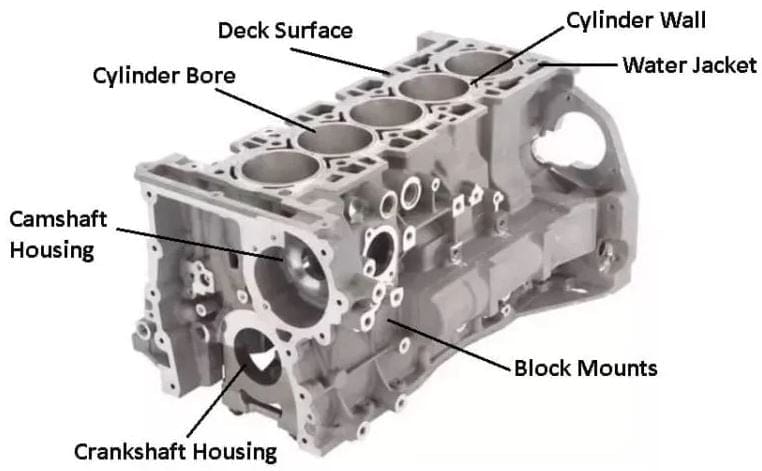

The cylinder block is one central component of the engine in an automobile. The engine block structure contains the cylinders and other engine parts of an internal combustion engine. It is also called an Engine Block.

The cylinders, cylinder head, and crankcase are the major three parts that form the foundation of an automobile engine.

The cylinder includes the piston, piston ring, and piston pin which is used to perform the combustion process. It also includes elements such as the coolant passages and oil galleries which provides circulation and temperature control caused due to friction to various internal parts of the engine.

It also features water galleries to provide cooling to the engine and maintain the optimum temperature. An oil sump is present at the bottom of the engine block to store the oil for circulation.

Engine block plays an important role in terms of preventing damage to internal parts of an engine. Earlier, the engine block had a separate crankcase attached separately but modern engines have the crankcase integrated within the engine block.

The engine block provides support to the parts in and around the engine.

Materials used for Cylinder or Engine Block:

For the production purposes of the engine block, mainly grey cast iron is used. To increase the properties of the engine block, nickel and chromium are also added sometimes.

Aluminum is used in order to obtain a less weight component and performance improvement. In the aluminum block, cast iron or steel sleeves are used on the cylinder. Aluminum blocks help maintain uniformity of temperature due to more thermal conductivity.

The crankcase in the block is often made up of aluminum alloy and sometimes grey cast iron.

Cylinder walls are mostly designed with cast iron as it has lower wearing qualities. Also, some small engines use chromium plating on cylinder walls to reduce wear and improve the working life cycle.

Moreover, cast iron is preferred for the blocks as it has better wear quality and is easier to the machine. These parts are produced using a casting type production to ensure a solid foundation of the parts.

The structure of a cast-iron engine block includes phosphorus, sulfur, manganese, silicon, carbon, and iron(95%). In the case of an aluminum alloy cylinder block, it contains copper, tin, and aluminum (91%).

Functions of Engine Block:

Functions of an engine include a variety of tasks essential for the optimum working of an internal combustion engine. These include:

- Enclose the piston, connecting rod, and crankshaft making sure they work properly inside the cylinder.

- Transfer of the gas forces used in the engine for the combustion process.

- Crankshaft drive mounting.

- Provide connection of the cylinder heads.

- Mounting of the camshaft.

- Mounting of the crankshaft.

- Pathway for transportation of lubricants and coolants.

- Connecting to the transmission via the flywheel drive.

- Sealing of the crankcase with the help of an oil sump.

- Circulation of water in water-cooled engines to keep the engine temperature within the working range and avoid excessive expansion.

Cylinder or Engine Block Construction:

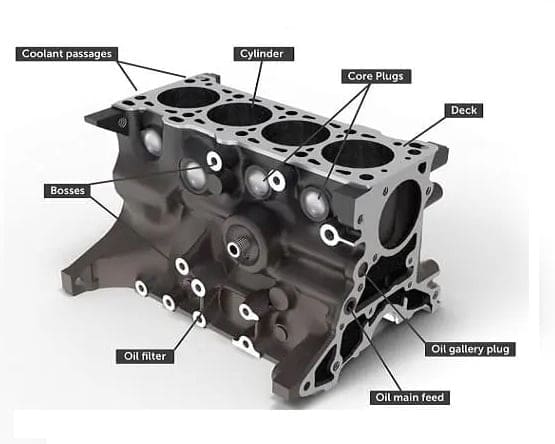

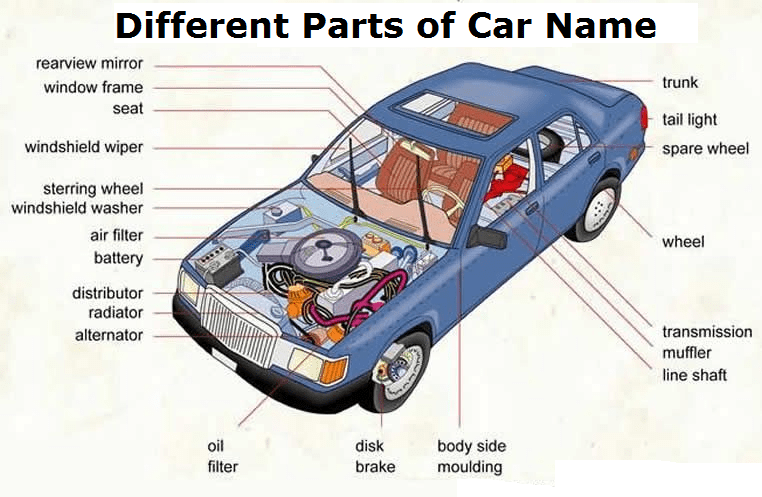

An engine block consists of the following major parts:

- Cylinders

- Cylinder head

- Water pump mounting

- Core plugs

- Oil passages

- Head studs

- Oil filter

- Crankshaft

- Crankcase

- Head gasket

- Intake and exhaust ports

- Head valves

Cylinders:

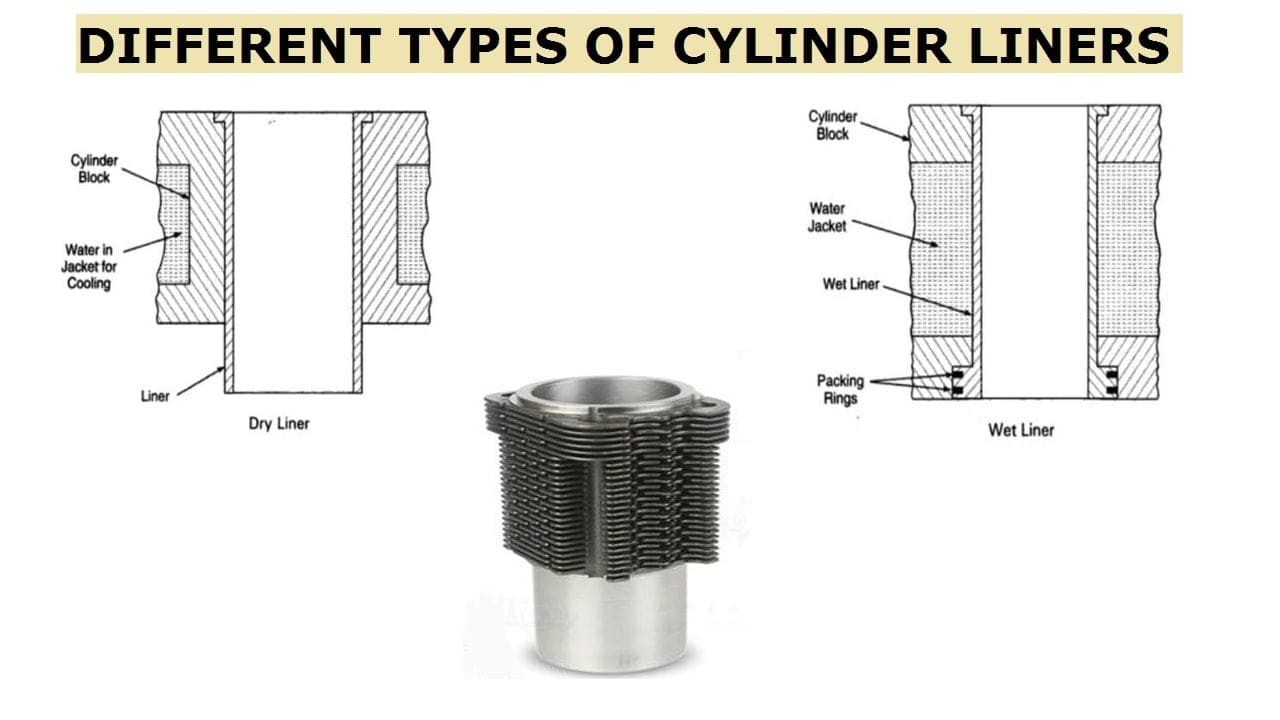

The cylinders of an engine block are considered the most important part of an engine. It is responsible for the compression of the air-fuel mixture and power generation of the engine. It is also called the compression cylinder.

These are cylindrical holes on the engine block which consist of a piston moving in the upward and downward direction inside the cylinder. Each cycle of the upward and downward movement is called a stroke.

Modern engines generally consist of 4-stroke engines which are namely suction/intake stroke, compression stroke, power stroke, and exhaust stroke. The air-fuel mixture enters in the suction stroke, gets compressed in the compression stroke, generates power in the power stroke, and gets released through the exhaust in the exhaust stroke.

The size and number of cylinders present in the engine decide the cubic capacity and power generation capacity of the engine. It varies according to the power required and the type of engine.

Cylinder head:

The cylinder head or deck is the portion that sits above the cylinder and forms the roof of the combustion process in the cylinder. It is the upper portion of an engine block. It consists of the intake manifold, exhaust manifold, and coolant passageways.

The major function is the flow of intake and exhausts air-fuel mixture in and out of the cylinders after combustion. Another major function of the cylinder head is cooling the engine.

Methods of cooling are using two mediums, air, and water. Modern engines prefer water cooling rather than air cooling.

The coolant water flows through different parts of the engine block through the passages to the cylinder head and absorbs the heat produced in the combustion chamber. Generally made up of gray cast iron or aluminum alloy.

Water pump:

The water pump is located at the end of the cylinder head and is driven by a belt which also drives the alternator. It is also called a coolant pump. It supplies and regulates the circulating coolant water to the engine block required for cooling the engine through the coolant passages.

It is a very vital part of the cooling system as it ensures the engine maintains optimum working temperature and prevents overheating of the engine.

Core plugs:

The function of the core plug is to stop the coolant water from leaking out from the engine. It acts as a cap of the engine block at the end of the coolant passages.

Oil passage:

Lubrication is very important for the proper working and maintenance of the engine. The oil passages and galleries of the engine block are used to supply oil to lubricate different parts of the engine.

Head studs:

Head studs are used to withstand high loads to keep the cylinder head sealed tightly against the block.

Threads are cut out equidistant from the center of the engine block in a single axis and provide accurate clamping forces. Head studs are preferred because they are less likely to twist when exposed to torque.

Oil filter:

The oil filter is generally located at the tail end or under the cylinder block. The function of this filter is to remove as many contaminants as possible before the lubricating oil is recirculated into the engine.

Crankshaft:

The crankshaft is the rotating part in the engine which brings about the movement in the piston and is converted into strokes.

It is connected to the connecting rod on which the piston is mounted. When the crankshaft rotates it causes up and down movement of the connecting rod thus affecting the piston.

Crankcase:

The crankcase is the casing of the crankshaft. It is mostly located below the cylinder block. It is used to avoid contamination of the crankshaft material. It may also contain a camshaft and an oil pump, depending upon the design of the engine.

Head Gasket:

It is the gasket located in between the cylinder head and cylinder block. It is responsible for acting as a sealant and separating the flow of elements in the head and block.

A broken head gasket can result in coolant from the head mixing up with the elements in the cylinder block.

Inlet and exhaust ports:

These ports are part of the cylinder head. An intake port is used to supply air into the combustion chamber through a channel.

An exhaust port is used to remove the gases after the combustion process and avoid the buildup of internal pressure in the chamber.

Head valves:

The purpose of valves in the engine is to stop or prevent the entry of air and fuel into the combustion chamber.

Each cylinder has two valves namely, the intake valve and the exhaust valve. The intake valve is comparatively larger in size and the exhaust valve is smaller in size.

Types of Cylinder or Engine Block:

The engine blocks are classified on the configuration of the engine. The types of engine blocks are as follows:

V Engine Cylinder:

V engine is a common engine type. It dates back to 1889 when it was first designed and used by Wilhelm Maybach on the 1889 Daimler Stahlradwagen automobile.

The engine is configured in such a way that two rows of cylinders or cylinder banks are arranged in a v-like structure when viewed from the front angle.

The cylinders are equally distributed in the banks. In other words, the configuration is such that the base of the cylinders intersects. These types of engines can offer loads of capacity in a much smaller amount of space. It is because the complex configuration helps to package the cylinders efficiently.

For example, V6 and V8 engines consist of 6 and 8 cylinders respectively. These cylinders are arranged in such a way that there are 3 and 4 cylinders in a cylinder bank respectively. The two-cylinder banks are fixed at a specified angle to each other. It is generally between 60° to 90°. The angle is termed a V-angle.

This type of engine contains a common crankshaft and the connecting rod of two opposite cylinders are connected to the same crankpin. In comparison to other engine types, V-engines are found to have shorter lengths but at the same time, they have a quite large width.

Another significance is the positioning of the camshaft in V-engines. The camshaft is generally overhead which is termed as overhead cam (single camshaft) or dual overhead cam (double camshaft).

V-type engines help reduce the height, width, and length of the engine considerably. As a result, V-engines are preferred for engines exceeding 3.0-liter capacity. The reduced engine size decreases the bonnet height of the vehicle. This provides better aerodynamics and smoother operation at high speed.

These produce higher torque at low speeds, as compared to other engines. Even though the size benefit cannot be overseen, V-engines offer disadvantages due to the complex structure. The weight distribution is not completely even and maintenance or replacement of parts can be a tedious task.

Another disadvantage of the V engine is that it cannot easily handle an odd number of cylinders. The odd-numbered cylinder can vibrate if the number of cylinders is not balanced.

Examples of V-type engines are V6, V8, V14, and V16. Some of the cars present with the v-type engine are the Mercedes Benz E 400, Toyota Camry, BMW 5 series, 6 series, and 7 series models, and Ferrari 458 special model.

Inline Engine Cylinder:

In this type of engine, the cylinders are arranged in such a way that it is in a series or in a single straight line. It is also known as a straight engine.

Inline engines are preferred for engines having a capacity lower than 3.0 L. These have simple and robust structures which are considerably easier and cheaper to manufacture. It can accommodate 2 to 8 cylinders in a straight line.

It houses the engine’s camshaft with tappets and pushrod arrangement. The valves are either placed in the cylinder head or the block next to the pistons. The cylinders are aligned in one single row along with the crankshaft.

As compared to other engines, inline engines provide much better balance due to even weight distribution. Inline engines are easy to maintain and repair due to their simple structure.

These can easily handle odd-numbered cylinders since there are single cylinders placed one after the other and there is no room for an uneven number of cylinders.

However, these produce less torque than V-engines at a slow speed. Some of the cars which use inline engines are Kia Seltos, Tata safari, BMW 520d, and Mahindra XUV700.

Boxer Engine or Opposed Engine Cylinder:

The cylinder block in a boxer engine consists of two banks of cylinders. It is like a flat-pressed version of a V-type engine. It is also known as the horizontally opposed engine due to its flat structure.

The cylinder banks are located on either side of the central crankshaft in this engine. It is called a boxer engine due to the motion of the piston being similar to that of a boxer’s fist in the horizontal plane.

But the only difference is that the pistons (cylinder bank) move in the opposite direction as opposed to the boxer’s fist moving in the same direction. The pistons in the opposite direction move toward and away from the central crankshaft at the same time. The boxer engine is a more complicated engine type as compared to other types.

While the inline and V-type engines are tall and narrow, the boxer engine is more rectangular in structure. It contains more components which increase the cost of manufacturing. The complicated layout of the engine makes it more difficult to access the parts for replacement.

Boxer engines offer a low center of gravity and perfect balance which allows the engine output to flow directly into the transmission without any losses, increasing the efficiency.

The opposite movement of pistons balances the required counterweight on each other. Hence these do not require any counterweight or dampening systems. Boxer engines can provide high continuous torque but require a proper cooling system.

Moreover, these can take up loads of space for a high-capacity engine. Reliable brands such as Subaru and Porsche still use the boxer engines in cars such as Porsche 911, Porsche 718, Subaru Forester, and Subaru Outback.

Common problems in the Engine Cylinder Block:

Symptoms

Common signs which indicate a malfunctioning engine block is low engine compression, visible engine smoke, engine overheating, discoloration of engine oil, leaking oil or coolant, frozen coolant in the radiator, and excessive smoke from the exhaust, low levels of coolant, blocked engine radiator and leaking antifreeze.

Coolant leakage:

External coolant leakage is a common problem in an engine block. It can be caused due to a malfunctioning water pump, radiator, or heater core. A clogged water pump interferes with the flow of coolant.

It can also be caused due to a malfunctioning cooling fan which can cause trapping of the heat inside and cause overheating of the coolant.

A crack in the engine block can also be a cause of leakage of coolant, leaving the engine to be overheated.

Cracked engine block:

A crack in the engine block occurs due to increased thermal stress in the material. It is caused due to overheating of the engine.

The block can also crack in freezing temperatures if the cooling system is not filled with enough antifreeze.

A crack in the engine can cause low engine compression. It can also lead to coolant or oil leak and emit white smoke from under the hood.

Porous engine block:

An engine failure can occur when a contaminant enters the metal. It is related to the manufacturing process of the engine block.

These casting defects do not create issues in a short time but eventually will begin to seep and leak.

Blown head gasket:

The Head gasket is located in between the head and the block.

A blown head gasket leads to the mixing of all engine fluids into the combustion chamber and causes excessive smoke out of the tailpipe, low compression in the cylinders, and a loss of coolant and milky oil.

Poor lubrication:

The lubrication of moving parts inside an engine is absolutely essential. Low engine oil levels can cause unnecessary friction inside the engine leading to overheating of the parts and damage to the engine. It could also cause an engine seizure.

Oil pump failure:

The oil pump is responsible for the flow of lubricant in the engine. Failure of an oil pump can have a long-term effect on the lifespan of the engine.

It would starve the engine of necessary lubrication and lead to excess friction between the moving parts.

Hydrolocking of engine:

The pistons of a combustion engine are designed to compress a mixture of air and fuel. Air can be compressed easily but compressing water is a difficult process.

As a result, if too much water enters the cylinder block the piston or components related such as the piston rod will likely break while trying to compress water at high RPMs.

A blown head gasket or driving the vehicle in floods can cause hydro locking of the engine.

More Resources:

- Electronic Ignition System

- Magneto Ignition System

- Battery Ignition System

- Rack and Pinion Steering

- Lubrication System Types

- Flywheel, Camshaft

- Open Belt Drive vs Cross Belt drive

- Drum Brake vs Disc Brake

- Propeller Shaft

- Air suspension system

- Brake System

- Chassis Frame

- Clutch complete Notes

- Single Plate Clutch

- Multi-Plate Clutch

Media Credits:

- The picture has been modified by the author and has taken reference from theengineerspost.com

- Feature Image modified by the author.

Discussion about this post