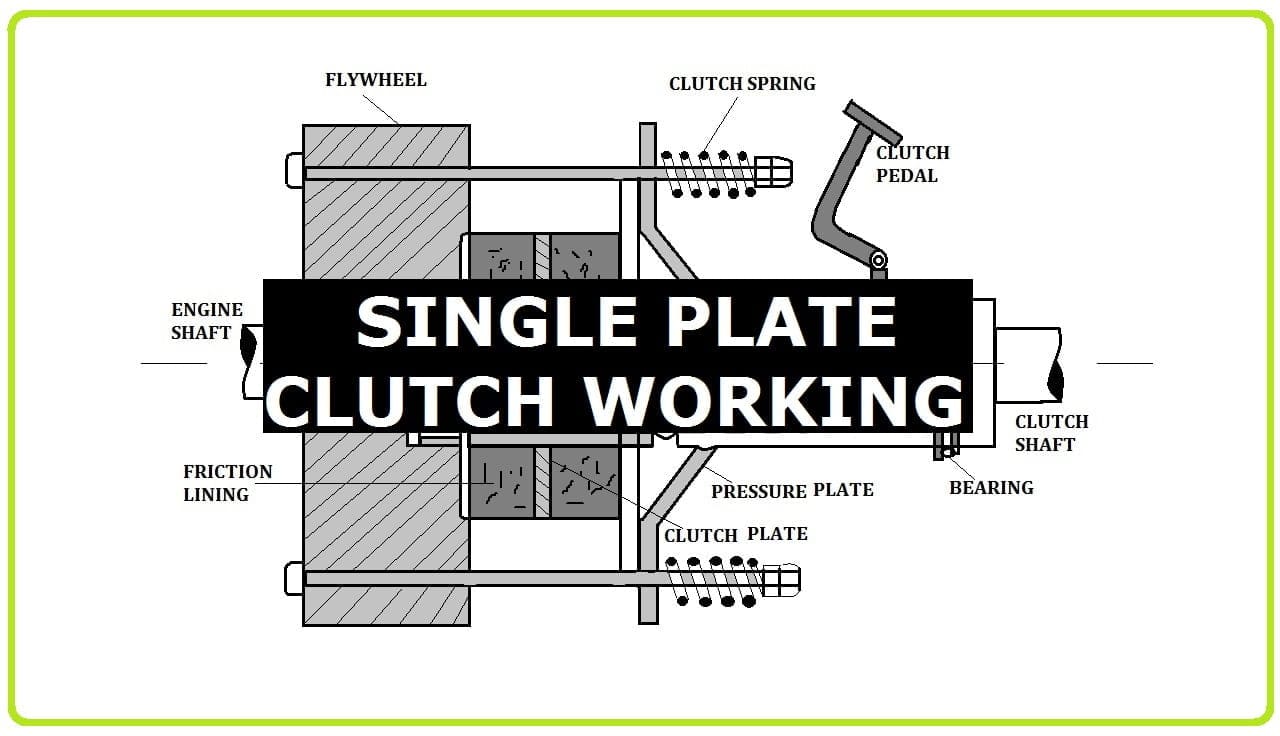

In this article, we will study What is Single Plate CLutch? and its subtopic like Definition, Construction or Parts, Working Principle, Advantages, Disadvantages, and Application in detail.

Note: At the end of the article you can easily download whole articles in PDF format.

So let’s start with the definition of Single Plate Clutch,

Single Plate Clutch Definition:

Single plate clutch has only one clutch plate that is mounted on the splines cut off the driving shaft and the flywheel is mounted on the engine crankshaft and rotates with it. The force of friction is employed to start out the driven shaft from zero rpm and make it gradually to the proper speed without excessive slipping of the friction surfaces.

There should not be excessive sleeping for better power transmission. friction clutch plays an important role in connecting the engine to the driven shaft.

In operating such a clutch, care should be taken for that the friction surfaces engage easily and gradually and it will bring the driven shaft to the proper speed.

For proper load transfer, proper alignment of the bearing must be set and maintained and it should be located as close to the clutch as possible for less fatigue failure.

Now moving to Construction,

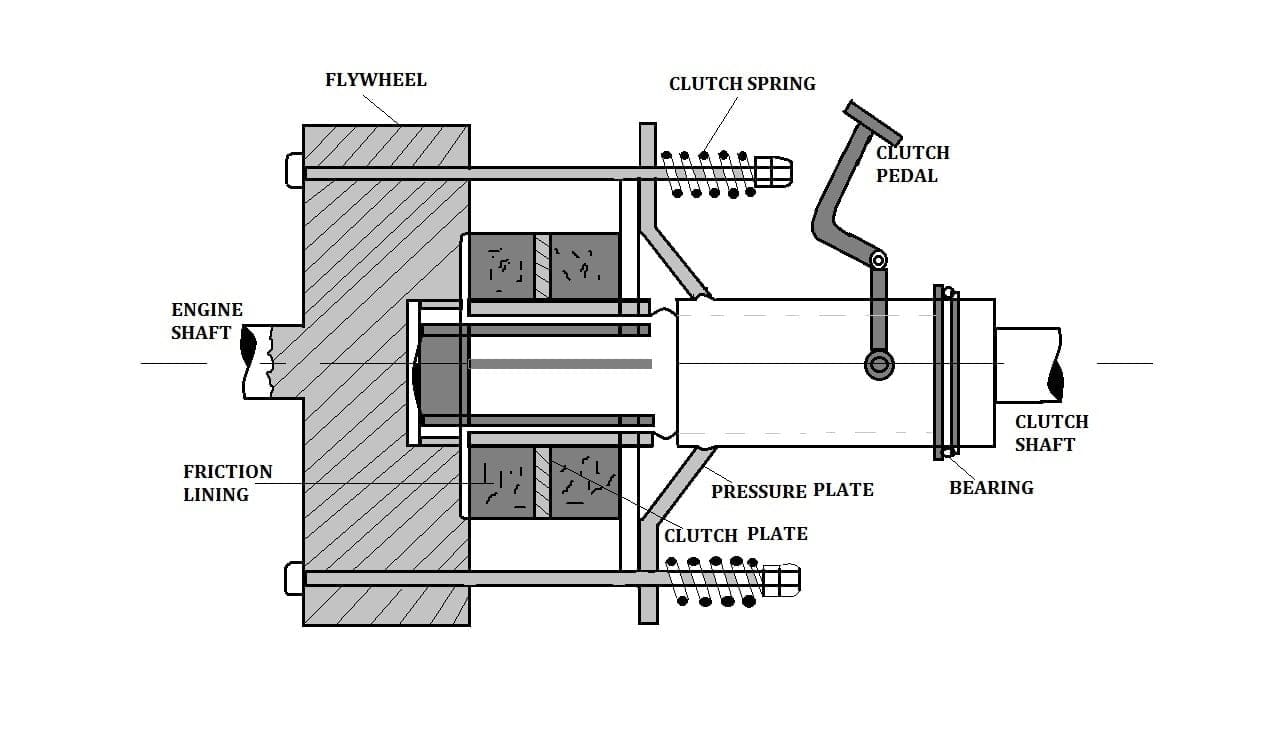

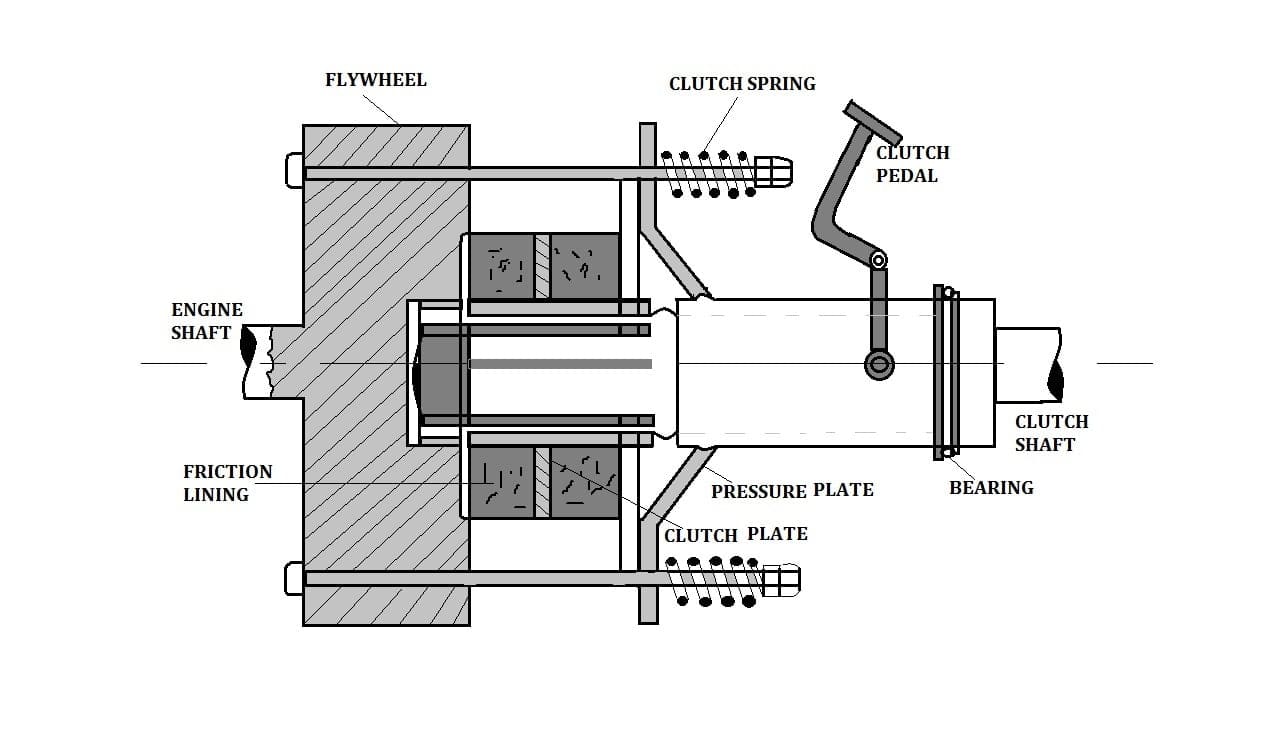

Single Plate Clutch Main Parts or Construction:

Single Plate clutch consists of the following Main Parts:

- Engine Shaft

- Flywheel

- Friction Lining

- Clutch Spring

- Clutch Plate

- Pressure Plate

- Clutch Pedal and

- Bearings

Engine Shaft:

An engine shaft is a rotating shaft that converts one form of motion into another. It is directly attached to the engine mechanism by which clutch parameters act on it.

One is the driving shaft that is attached to the engine, the other one is the driven shaft that will run in conjunction with the driving shaft via a gearbox.

Flywheel:

Flywheels store energy by using a rotating wheel in which energy stored increases as the square of the angular velocity and only linearly with the moment of inertia.

The high angular velocities attained can result in the material disintegrating due to the forces involved. During engagement and disengagement, it acts as a source of energy whenever required

Friction Lining:

Friction Lining is a friction disc that assists the clutch in starting and stopping the energy continuation between a driven shaft and a drive shaft.

Friction linings have a low coefficient of friction so they create quiet, stable, and smooth operations. Material of friction lining is asbestos, fiberglass, silicon dioxide.

Thrust Spring:

Helical-coil thrust springs inserted between the pressure plate and the cover. When in the mode of compression, It provides the necessary torque so that it loads the pressure plate against the driven plate when the clutch is engaged. It is made up of high tensile steel and nickel chrome steel.

Clutch Plate:

One clutch plate is used in a single plate clutch. It is one of the main components of clutches. The clutch plate is a thin disc-type metallic plate that has both side friction linings. The frictional surface will provide the necessary torque to transmit.

Pressure Plate:

The pressure plate creates pressure on clutch plates to maintain proper contact between the surfaces of the flywheel and clutch plate by means of spring which are attached to it. The pressure plate is generally made up of cast iron.

Clutch Pedal:

It is the operating parameter of the clutch by which the driver operates the clutch. The driver has to press the pedal when the gear is to be applied. It is a set of mechanical linkages which assists in the engagement and disengagement of the clutch.

Release Bearings:

The release bearing is also called throw-out bearing.it is located around the input shaft at the back of the pressure plate.

Release bearing decreases the friction between the release fork and the clutch pressure plate lever so wear out of the pressure plate will be less. The bearing should be lubricated properly. Mechanical bearings and hydraulic bearings are types of release bearings

Single Plate Clutch Working Principle:

The pressure plate is bolted to the Flywheel with the help of clutch springs because of the splines cut on the shaft. It is free to slide on the clutch shaft when the clutch pedal is operated.

A single plate friction clutch consisting of two flanges. One flange is strongly fitted to the driving shaft, while the other is free to move along the driven shaft due to splined connection.

The action force is provided by a spring which makes forces the driven flange to move towards the driving flange. The face of the drive flange is attached with the help of friction material such as cork, leather, and asbestos.

The pressure plate is backed by the release levers attached against the compression spring so that the friction linings on the clutch plates are free from Flywheel and pressure plate.

When the pressure plate is released the compression springs are free to move the pressure plate to the left side making it bring in contact with the clutch.

The pressure plate will move to the left sliding to the clutch plate on the splined cut on the hub along the driven shaft until the friction lining will touch the Flywheel cone.

The compression springs now cause the linings to be gripped between the pressure plate and the Flywheel and the friction between the linings Flywheel and pressure plate causes the clutch plate to revolve around the driven shaft.

Single plate torque transmitting capacity is quite less and heat generation is less and the coefficient of friction is high.

Single Plate Clutch Working Animation Video in Hindi:

Single Plate Clutch Advantages:

The following advantages of single plate clutch are:

- A single plate clutch is not that much expensive.

- It requires less maintenance due to fewer special parts in it.

- Gears will shift in an easy way due to the control movement as compared to the cone clutch where the forces are acting in the inclined direction.

- A single plate clutch is more reliable it will not bind like in the cone clutch.

- Slippage is quite less.

- There is very less power loss

- Heat generation is quite less

- Very fast engagement and disengagement

Single Plate clutch Disadvantages:

The following disadvantages of single plate clutch are:

- The greater force is required to disengage because the springs have to be stiffer.

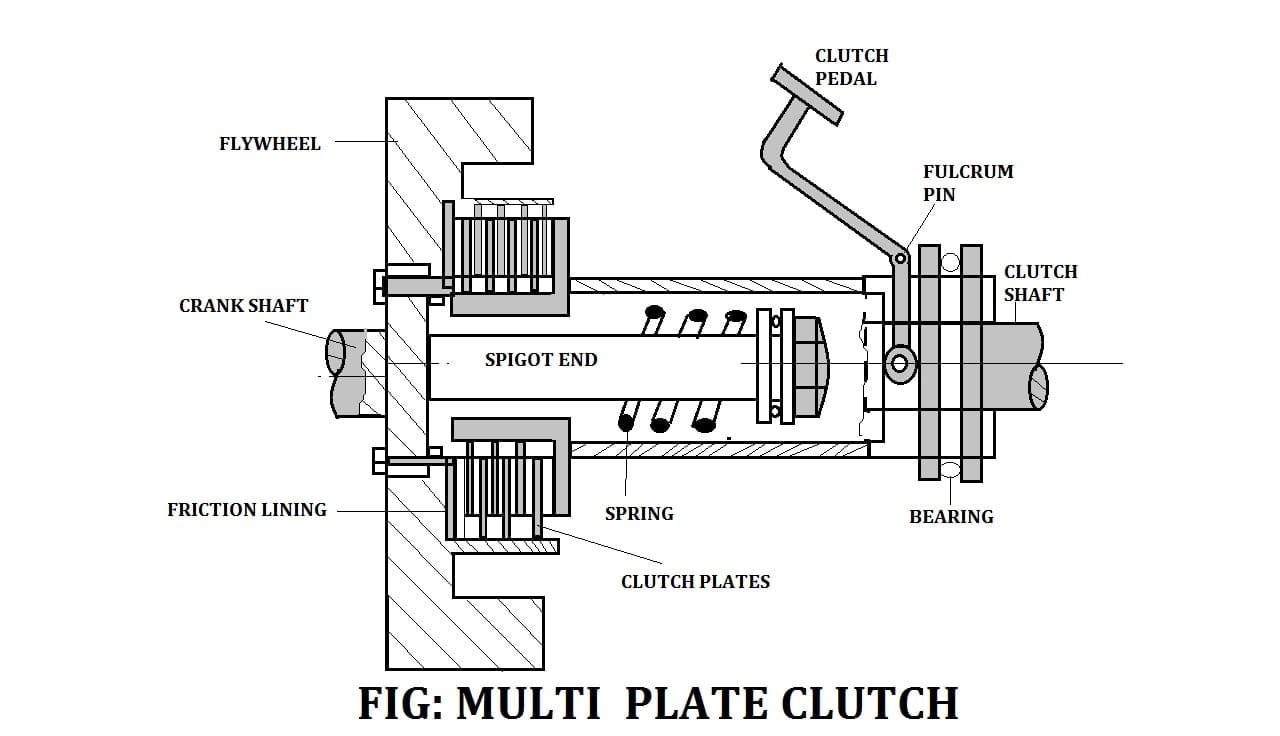

- Torque transmitting capacity is very less as compared to the multi-plate clutch.

- Large space is required in a single-plate clutch.

Single Plate Clutch Application:

The following application of single plate clutch are:

- Single Plate Clutch is the type of friction clutch, The main application in the transmission of the power of driving and driven shafts and

- It can also be used on machines that must be started and stopped instantaneously.

- Its application is also found in cases in which power is to be delivered to machines at partial load or maybe at full load.

Conclusion:

- Uniform pressure theory is applicable for new friction plates or lining.

- Uniform wear theory is applicable for worn-out friction lining and friction plates.

- Friction radius r for the new clutch is slightly greater than old clutches because of the worn-out tendencies.

- Torque transmitting capacity of new clutch slightly higher than the old clutch

- Major life of friction lining comes under the criteria of uniform wear criterion.

- It is logical and safer to apply uniform wear theory for the design of clutches

- The service factor is to compensate for the starting torque.

- Location of the clutch is the important criteria for low torque capacity requirement

- The contact surfaces should have the ability to develop a friction force that will start picking and hold and grip the load

- With a large amount of low-pressure condition between the contact surfaces.

- The heat of friction should be instantaneously removed and dissipated from the area and the tendency to grab should be minimum.

Internal Resources:

- Clutch complete Notes

- Multi-Plate Clutch

- Open Belt Drive vs Cross Belt drive

- Drum Brake vs Disc Brake

- Electronic Ignition System

- Lubrication System Types

- Magneto Ignition System

- Battery Ignition System

- Flywheel, Camshaft, Crankshaft

- Air suspension system

- Synchromesh Gearbox

Reference [External Links]:

This is from my side on Single Plate Clutch. Let me know if you understood or not? and If yes Please share it with your friends too. Till then Thank you so much. We will meet in another article.

![Pneumatic System: Definition, Components, Working, Advantages [Notes & PDF] Feature Image of Pneumatic System](https://themechanicalengineering.com/wp-content/uploads/2022/07/Feature-Image-of-Pneumatic-System-300x155.jpg)

![Aluminum: Introduction, Characteristics, Different Types, Application [Notes & PDF] Feature Image of Aluminum Types](https://themechanicalengineering.com/wp-content/uploads/2022/10/Feature-Image-of-Aluminum-300x150.jpg)

![What is Pulley? Different Types of Pulley [Notes & PDF] Feature Image of Pulley](https://themechanicalengineering.com/wp-content/uploads/2022/07/Feature-Image-of-Pulley-300x267.jpg)

![What are the Different Types of Car Lights & Headlights? [Notes & PDF] Feature Image of car Headlight](https://themechanicalengineering.com/wp-content/uploads/2022/10/Feature-Image-of-car-Headlight-300x192.jpg)

![Different Types of Measuring Tools and their Uses [Notes & PDF] Feature Image of Types of Measuring Tools](https://themechanicalengineering.com/wp-content/uploads/2023/01/Feature-Image-of-Types-of-Measuring-Tools-300x171.jpg)

![Steel: Properties, Different Types and Applications [Notes & PDF] Feature Image of Steel](https://themechanicalengineering.com/wp-content/uploads/2023/01/Feature-Image-of-Steel-300x168.jpg)

Discussion about this post