Battery Ignition System is used in Automobile (IC Engine) to produce a spark in the spark plug for the combustion of fuel.

Today in this article we will study Definition, Parts or Construction, Working, Advantages, Disadvantages, and Application of Battery Ignition System.

The PDF you can download at the end of the article.

So let’s start definition first,

Battery Ignition System Definition:

A battery ignition system is used in the SI engine for supplying the power to the spark plug for the generation of spark to burn the air-fuel mixture in the SI Engine system.

Now come to the construction,

Battery Ignition System Construction or Parts:

Battery Ignition System consists of the following Main Parts:

- Battery

- Ballast Resistor

- Ammeter

- Ignition Switch

- Primary Winding

- Contact Breaker

- Capacitor

- Secondary Winding

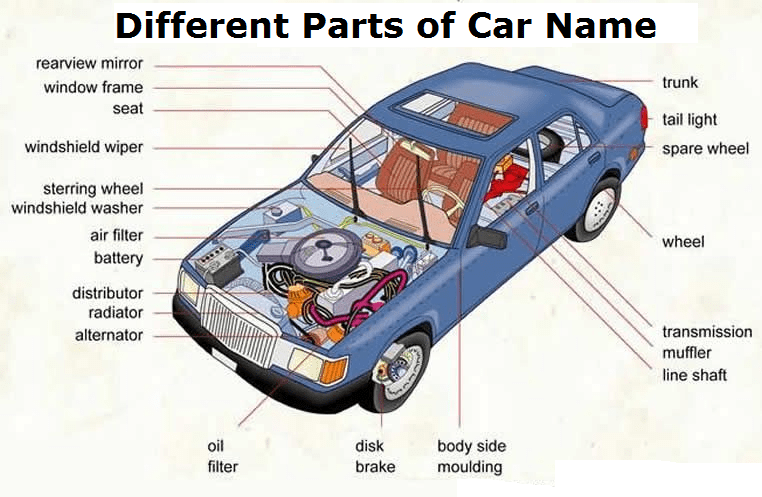

- Distributor

- Spark Plug

Battery:

The battery is used here is a rechargeable lead-acid battery. It stores electrical energy and is used to provide electricity for ignition. The battery is charged by the dynamo which is driven by the engine. The battery is connected to the Ignition switch.

Ballast Resistor:

The ballast resistor controls the current that passes through the primary winding.

It is made up of Iron and Iron has the property to increase electrical resistance rapidly by an increase in temperature at a certain limit. This additional resistance resists the flowing current which controls the temperature of the ignition coil.

It helps to maintain the temperature under the prolonged condition and Here It is connected in series with primary winding to regulate the current in the primary winding.

Ammeter:

It is a measuring instrument used for measuring the current.

Ignition Switch:

It is an important part of the system. It is used for ON and OFF the system.

Ignition Coil:

An ignition coil is the main part of the battery ignition system which is used to step the voltage that means low to high and that is used for generation of spark in the spark plug.

Ignition Coil consists of a magnetic core or soft wire, and two electrical winding called primary and secondary winding.

Primary Winding:

The primary winding has 200-300 turns. The current which is flowing through the primary winding creates a magnetic field.

Secondary Winding:

The secondary winding has 21000 turns of 40 gauge wire. It is insulated to withstand high voltage. As you can see in the diagram one end is connected to the PW and the other ends to the distributor.

Contact Breaker:

The name itself indicates ‘contact breaker’ it means adding and breaking the primary circuit to the ignition coil.

The function of the contact breaker is current flows in an ignition coil when it is closed and flows stop when it is open. In the above diagram, you can see it’s close.

Capacitor:

It is similar to an electric capacitor. Generally, It stores electrical energy in an electric field. In capacitor two metal plates are separated from each other through the air which is an insulating material.

The main function of the capacitor is to prevent the arc from across the breaker point and if it is not connected to the primary circuit the induced voltage would cause an arc across the breaker point and that is very dangerous.

Distributor:

The distributor also plays a vital role in this system. It provides ignition pulses to the individual spark plug-in sequences at the correct time.

There are 2 different types of distributors.

- Brush Type and

- Gap Type

Spark Plug:

As you can see in the diagram each Spark plug is connected with the distributor. The spark plug is used for injecting the spark and which causes the start burning of the air-fuel mixture in the system. Spark plug used in SI Engine.

Battery Ignition System Working Principle:

The working of batter system is,

When the ignition switch is turned ON, the primary circuit gets closed and the current starts flowing through it. This current sets up the magnetic field around the soft iron core of the coil.

The current starts flowing through the condenser when the breaker points open, and when it closes the current is flowing through the contact breaker.

When the current passes through the condenser, the condenser charges, the primary current falls, and the magnetic field gets collapses.

This change in the magnetic field induces a current in the primary winding that flows in the same direction as the primary current.

And charges the condenser voltage to much higher than battery voltage thus stopping the current flowing from the battery.

Due to these processes, the condenser gets discharged into the battery. Now reverse the direction of the primary current and magnetic field induces a high voltage in the secondary winding.

Now the high voltage sends to the distributor by the high tension wire. Between distributor and spark plug an ignition harness is connected as you can see in the diagram.

Now the current passes to spark plug one by one and it will produce spark for the burning of an air-fuel mixture.

Battery Ignition System Working Video (English):

Battery Ignition System Advantages:

The main advantages of a Battery System are:

- The battery System gives more power output.

- Fuel efficiency is also good.

- There are no moving parts here.

- Better combustion because in other convention systems only 70 to 75 percent air-fuel mixture gets burned but here more than 90 percents get burns.

- Spark intensity is also good.

Battery Ignition System Disadvantages:

It is having some disadvantages too and those are:

- Battery Ignition takes more space compared to other electronic ignition systems.

- The battery is essential for generating the spark when the battery is discharged it won’t start.

- It won’t produce a spark when the spark plug is fouled.

- More Maintenance because of Arcing, Pitting of contact breaker point.

Battery Ignition System Application:

The following application of Battery Ignition System:

- Firstly Battery System is used in SI Engine for producing the spark to the spark plug.

- It is also used in light commercial and Modern vehicles which are having SI engines.

Internal Resources for You:

- Clutch complete Notes

- Flywheel, Camshaft, Crankshaft

- Drum Brake vs Disc Brake

- Electronic Ignition System

- Single Plate Clutch

- Multi-Plate Clutch

- Lubrication System Types

- Magneto Ignition System

Reference [External Links]:

- https://www.sciencedirect.com/topics/engineering/ignition-systems

- https://en.wikipedia.org/wiki/Ignition_system

- https://osme.co.in/wp-content/uploads/2020/04/Ignition-system.pdf

- https://auto.howstuffworks.com/ignition-system.htm

So that’s it about Battery Ignition System from my side. If you like the article do not forget to share it on social media. And if you have any doubt related Battery Ignition System let me know in the comment box.

Discussion about this post