Introduction to Aluminum:

Aluminum is a silvery-gray metal, one of the most widespread metals on earth which makes up to 8 more than % of the Earth’s core mass.

It is the 13th element on the periodic table with the symbol Al and the third most commonly found metal on our planet after silicon and oxygen.

Also spelled Aluminium, pure aluminum does not occur in nature as it tends to bind with other metals easily. As a result, aluminum was produced for the first time as late as 1824.

The most commonly found form in nature is aluminum sulfates.

Aluminum has a lower density as compared to the other metals (one-third of steel). It forms a protective layer of oxide on its surface when exposed to the air, due to its greater affinity toward oxygen and also forms compounds primarily in the +3 oxidation state.

The strong affinity to oxygen leads to its common association with oxygen oxides, as a result, this is found mostly in the rocks in the crust rather than in the mantle.

Al3+ aluminum cation is highly charged and small. The boiling point is denoted around 2743 K and the melting point of aluminum is around 933.47 K.

The production of aluminum metal is associated primarily with bauxite ore which contains around 40% to 50% hydrated aluminum oxide mixed with silica and iron oxide.

Even though it is chemically similar to steel or copper, aluminum is a lightweight, strong, noncorrosive, flexible, and intently recyclable metal.

Steel is stronger than aluminum physically but this is preferred instead due to its low density and flexibility which is used for aircraft components, window frames, ships, and highrise buildings.

Aluminum is around 2.5 times denser than steel which makes it an alternative for requiring mobility and portability.

Aluminum alloys are generally highly ductile and malleable, hence they can be easily formed and machined.

Also good electrical and thermal conductors, non-sparking, and non-magnetic, aluminum materials have numerous applications in our lives.

It is highly recyclable, requiring low re-melting energy, which is only around 5% of the energy needed to produce the primary metal. 75% of the material is recovered for reuse without losing its desirable properties.

Characteristics of Aluminum:

#1. Lightweight:

The specific weight of aluminum is 2.7 g/cm^3, which is around a third of that of steel. This helps reduce the cost of manufacturing.

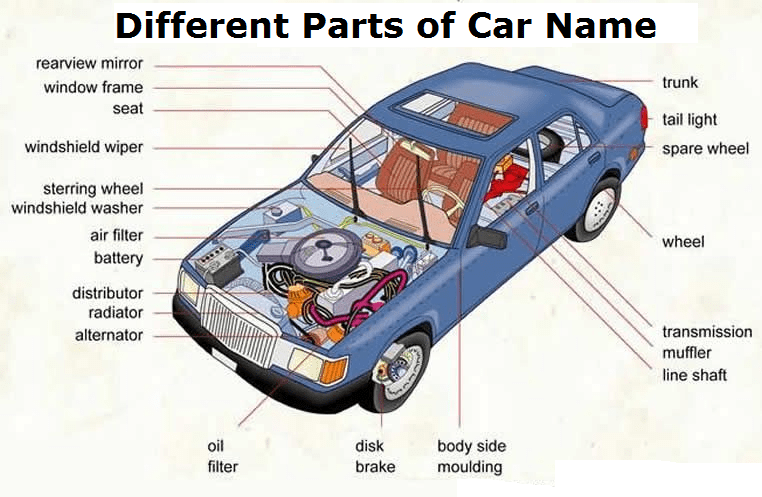

The use of aluminum in automobiles reduces dead weight and energy consumption while increasing the load capacity.

Moreover, the strength can be changed o adapt to the application by modifying the composition of the alloys.

Aluminum-manganese-magnesium is the preferred mix for durability with strength while aluminum-magnesium-silicon alloy is preferred for automobile sheet metals.

#2. Corrosion Resistance:

A thin oxide coating is produced naturally by aluminum. It acts as a protective film that prevents the metal from making much contact with the environment.

This is useful for applications where it is exposed to corroding agents such as vehicles.

However, aluminum alloys are much more corrosion-resistant than pure aluminum (marine magnesium-aluminum alloys being an exception).

#3. Electrical and Thermal Conductivity:

According to its weight, Aluminum is an excellent conductor of heat and electricity, being twice as good a conductor as copper.

This has resulted in the first choice preference of aluminum for power transmission lines. Also, an excellent heat sink is used in appliances that require sudden and rapid heat drains.

#4. Reflectivity:

Aluminum is an excellent reflector of visible light along with heat. Its low weight in addition makes it an excellent material to be used for reflectors, for example, light fittings or roof blankets.

Cool roofs made up of reduces the internal solar heat within the house, reflecting up to 95% sunlight.

#5. Ductility:

It has a low melting point and density. This allows it to be processed in several ways into a molten state.

The ductility of aluminum ensures the fluidity of design if the product is maintained until the end. Sheets, foil, tubes, rods, and wires all consist of aluminum.

What are the different Types of Aluminum?

To modify its properties such as formability, corrosion resistance, and machinability, pure aluminum is often combined with different elements. However, the alloys need to be identified and thus needed grading for identification.

The aluminum association created a grading system for the identification of aluminum alloys and is responsible for maintaining the nomenclature of the standard grades.

It is graded according to the main alloying element along with its thermal and mechanical properties.

Aluminum alloys are classified mainly into two categories: Wrought and Cast aluminum. Both categories have differently assigned designation systems.

Wrought Aluminum:

Wrought is manufactured by melting aluminum ingots along with a certain amount of the specific alloying element, which results in the composition of the grade. The aluminum alloy is then cast and the other mechanical processes until extrusion.

A four-digit number is used as a code to identify each grade:

The first digit refers to the primary alloying element mixed with pure aluminum. The primary alloying element has major effects on the properties of the grades in a series.

The second digit indicates the modification of a specific alloy. The modifications require specific documentation and are registered with the IADS. If the designated number on the second digit is zero, the alloy is original/unmodified.

The third and fourth digits are numbers assigned to a specific alloy in the series. For example, in the 1000 series, these digits indicate the purity of the alloy.

The table below describes the wrought aluminum series:

| GRADE | PRIMARY ALLOYING ELEMENT |

| 1XXX | 99.00% Aluminum |

| 2XXX | Copper |

| 3XXX | Manganese |

| 4XXX | Silicon |

| 5XXX | Magnesium |

| 6XXX | Magnesium and silicon |

| 7XXX | Zinc |

| 8XXX | Other Elements |

The following explains the series of wrought grades:

1000 Series

The 1000 series contains at least 99.0% aluminum with no significant alloying element. This series consists of aluminum grades that have excellent corrosion resistance and high electrical and thermal conductivity.

These are highly formable and work hardens very slowly due to their ductility and relative softness. Hence for processes requiring severe deformation, they are preferred.

They are weldable but have a very narrow melting range. However, the mechanical strength in these grades is comparatively lower.

Aluminum 1100 is the most common grade in the 1000 series. It has the highest mechanical strength in the 1000 series and is also known as pure commercial aluminum. This grade is suitable for heat sinks and heat exchange equipment due to good electrical and thermal conductivity, respectively.

This grade also has excellent forming properties, thus making it suitable for cold working processes such as bending, roll forming, drawing, stamping, and spinning.

Its ductility can be used to form wires, plates, foils, bars, and stripes. Along with cold working, hot forming is easily performed using this grade.

Conventional welding methods, including resistance welding, can be used to weld this grade. However, high-pressure applications can be performed using this grade.

This grade cannot be hardened by heat treatment and is only hardened by coldworking, like most of the alloys in this series.

2000 Series

The 2000 series aluminum grades consist of around 0.7-6.8% of copper and smaller amounts of silicon, manganese, magnesium, and other elements.

Copper is the primary alloying element for these grades. It imparts additional strength and hardness which helps to improve their machinability. These grades can maintain high strength at a wide range of temperatures.

2000 series aluminum grades are suitable for aircraft and aerospace applications as these are high-performance and high-strength alloys. However, the addiction to copper decreases ductility and corrosion resistance.

Moreover, these are heat-treatable aluminum grades. Precipitation hardening is also performed to increase their strength. During the heat treatment, the precipitation of the intermetallic Al2Cu increases the hardness of the alloy.

However, these grades could be challenging to weld due to the intermetallic compounds. Some of the 2000 series grades are not suitable for arc welding as they are susceptible to hot cracking and stress corrosion cracking.

Aluminum 2011 is a free-machining alloy and has excellent machinability properties (i.e. can generate small chips and give a smoother surface finish), thus making it suitable for the high-speed lathing process.

Though this grade is a highly versatile alloy, it has poor corrosion resistance which needs to be coated or anodized. Moreover, these are not recommended for forming and welding.

Aluminum 2024 is ideal for heavy-duty applications under stress for a long period. It is one of the widely known high-strength aluminum alloys.

This alloy has features such as good fracture resistance, fracture toughness, and low fracture crack growth. However, it requires it to be mitigated by cladding or anodizing to improve its poor corrosion resistance.

3000 Series

3000 series aluminum grades consist of manganese as the main alloying element, which comprises around 0.05-1.5% of the alloy.

The presence of Manganese gives the alloy greater mechanical strength than pure aluminum and it is maintained at a wide range of temperatures.

Characteristics include good corrosion resistance, high ductility along with formability. These are non-heat-treatable and are suitable for welding. Hardening can be obtained by a cold working process.

Aluminum 3003 contains 1.5% manganese and 0.1% copper, being the most widely used aluminum grade. This grade has the exact mechanical properties of Aluminum 1100 along with 20% higher tensile strength. This grade can be brazed, deep drawn, spun, and welded.

4000 Series

4000 series aluminum grades consist of 3.6-13.5% silicon as the primary alloying element, along with small amounts of copper and magnesium.

Silicon lowers the alloy’s melting point and helps in improving fluidity during the molten state. The 4000 series grades are a suitable option as a good filler material for welding and brazing.

Heat treatability of some grades under the 4000 series is dependent on the amounts of copper and magnesium in the alloy.

The addition of such elements gives a favorable response to heat treatment. The heat-treated grades can be preferred for welding.

5000 Series

5000 series aluminum grades contain 0.5-5.5% magnesium as the main alloying element. The grades in the series cannot be heat-treated and can be hardened by cold working.

They have high ductility in annealed conditions and moderate strength. These can be welded easily and have high corrosion resistance.

Moreover, these are excellent alkaline resistant. Some grades in this series contain 3.5% magnesium which is not suitable for high-temperature applications, as they are prone to stress corrosion.

Aluminum 5005 is generally used in sheet metal work. Features include good formability and are easy to bend, spin, draw, stamp, and roll form. These can withstand marine environments and are corrosion-resistant.

Aluminum 5083 contains some amounts of manganese and chromium. It can provide resistance to most industrial chemicals and seawater. It can retain its high strength after the welding process.

Aluminum 5052 offers better resistance to marine environments compared to other aluminum grades. It exhibits good finishing qualities and can be drawn and formed into intricate shapes due to its excellent workability. It has the highest strength among the non-heat-treatable aluminum grades.

6000 Series

6000 series aluminum grades consist of silicon and magnesium as the major alloying elements. The presence of silicon and magnesium in the alloy is around 0.2-1.8% and 0.35-1.5%, respectively.

To increase their yield strength, these grades can be heat-treated. The presence of high silicon content promotes precipitation hardening, which can result in reduced ductility.

However, this effect can be reversed with the addition of chromium and manganese, which can depress recrystallization. It is difficult to weld these grades because of their sensitivity to solidification cracking, thus proper welding techniques should be applied.

Aluminum 6061 is the most versatile among the heat-treatable aluminum alloys. It is also known as the “work-horse” alloy. Its characteristics include excellent formability and corrosion resistance (using bending, deep drawing, and stamping). These are suitable for welding and can be welded using any method.

Aluminum 6063 is an alloy commonly used for aluminum extrusion. It has high tensile strength and corrosion resistance along with excellent finishing qualities. It can produce smooth surfaces after forming intricate shapes, hence making it suitable for anodizing. Other characteristics include good weldability and average machinability.

Aluminum 6262 is a free-machining alloy. These have excellent mechanical strength and good corrosion resistance.

7000 Series

7000 series aluminum grades consist of 0.8-8.2% zinc as the main alloying element. Alloys with the highest strength are present in this series. These are heat-treatable grades that need to be followed by aging to increase their yield strength.

The presence of zinc leads to the precipitation of MgZn2 and Mg3Zn3Al2t, as a result, the intermetallic compounds harden the alloy.

Characteristics include high corrosion resistance, which can be enhanced by the addition of copper. The grades in this series have poor weldability as these are susceptible to stress corrosion cracking and hot cracking.

Aluminum 7075 has among the highest strengths among the aluminum grades. It is a high-performance alloy, with a higher tensile strength than Aluminum 6061. This alloy is harder and can withstand prolonged periods of stress. It is weldable using spot or fuse methods.

Cast Aluminum:

As the name suggests, cast aluminum is produced by a casting process involving pouring molten aluminum together with specific amounts of the alloying elements.

It is then molded to form the desired shape of the alloy. Cast aluminum alloys generally have lower tensile strength as compared to wrought aluminum. They are susceptible to cracking and shrinkage.

However, they are more cost-effective. Molten aluminum can flexibly take the shape of the mold cavities, as a result, these alloys can be molded into a wide range of shapes.

A four-digit code which also includes a decimal value is assigned to identify each cast aluminum grade:

The first digit is assigned to indicate the primary alloying element in the alloy

The second and third digits are arbitrary numbers, except for the 1XX.X series. These digits in the 1XX.X series indicate the purity of the pure aluminum alloy.

The last digit indicates whether the alloy is a cast or an ingot. These are represented by (“.0”) and (“.1” or “.2”).

The table below describes the cast aluminum alloy series:

| Series | Primary alloying element |

| 1XX.X | 99.00% Aluminum |

| 2XX.X | Copper |

| 3XX.X | Silicon with added copper or magnesium |

| 4XX.X | Silicon |

| 5XX.X | Magnesium |

| 7XX.X | Zinc |

| 8XX.X | Tin |

| 9XX.X | Others |

1XX.X Series

1XX.X series has the maximum amount of pure aluminum (99.00% minimum). These aluminum grades have high electrical and thermal conductivity, good reliability along with excellent corrosion resistance and finishing properties.

2XX.X Series

The 2XX.X series consists of copper as the primary alloying element. These aluminum grades are heat-treatable. Characteristics include high strength and low fluidity.

These also have low corrosion resistance and ductility. Moreover, these are susceptible to hot cracking.

3XX.X Series

The 3XX.X series contain silicon as the primary alloying element along with small amounts of magnesium and/or copper. These aluminum grades are heat-treatable.

Significant characteristics include high strength and good wear and cracking resistance. The increased amount of copper helps the grade be less resistant to corrosion. However, the ductility is comparatively low.

4XX.X Series

4XX.X series aluminum grades consist of silicon as the main alloying element. These have moderate strength.

These are non-heat treatable and also have good machinability due to their high ductility. Significant characteristics include good impact resistance, corrosion resistance along with casting properties.

5XX.X Series

5XX.X series aluminum grades consist of magnesium as the primary alloying element. The presence of magnesium makes these corrosion-resistant.

However, these are non-heat-treatable. Significant characteristics include good corrosion resistance and a very attractive appearance when anodized. The strength is moderate-to-high but these are machineable and have excellent casting properties.

7XX.X Series

7XX.X series aluminum grades contain zinc as the primary alloying element. These are heat-treatable grades.

Significant characteristics include high strength, good corrosion resistance, good dimensional stability, and good finishing qualities. However, the casting properties of this alloy are poor.

8XX.X Series

8XX.X series aluminum grades contain tin as the primary alloying element. These are non-heat-treatable alloys.

Characteristics are good machinability and wear resistance due to their low coefficient of friction. However, mechanical strength is comparatively low.

The series 6XX.X is not used in these standards.

Temper Designation of Aluminum Alloys

The temper designation system is designed to designate the response of a certain alloy to welding and other fabrication processes.

It is related to the strengthening and hardening processes the alloys have undergone. This destination system is used by both wrought and cast aluminum alloys.

The temper designation system of an aluminum alloy comprises a capital letter which is followed by a two-digit number for strain-hardened and thermally treated alloys.

It is separated from the alloy numbering designation by using a hyphen (e.g., 5052-H32).

The first character in temper designation is used to indicate the main treatment that the alloy has undergone.

| Letter | Treatment |

| F | As fabricated alloys, no treatment was performed |

| O | Annealed |

| H | Strain-hardened or cold-worked |

| W | Solution heat-treated |

| T | Thermally treated |

The first and second digits are used to indicate the operation after strain hardening and the degree of strain hardening respectively (for strain-hardened alloys).

The first digit indicates the thermal treatment condition for thermally treated alloys.

What are the use or Applications of Aluminum?

Wrought aluminum grades:

Aluminum 1100 is used in rivets, deep-drawn parts (e.g., pots, kitchen sinks), railroad tank cars, and reflectors. They are used in stocks, heat exchangers, and heat sinks due to their high thermal conductivity. Moreover, this grade is suitable for electrical applications.

Aluminum 2011 is used for manufacturing machine and automotive parts, fasteners, weapons, munitions, pipe and tube fittings, and atomizer parts. It is also applied to make screw machine products.

Aluminum 2024 is the most suitable aluminum grade for aircraft and aerospace applications. It is also extensively used in marine equipment, wing tension members, bolts, hydraulic valve parts, shafts, couplings, nuts, gears, and pistons.

Aluminum 3003 is used in the production of heat exchangers, pressure vessels, storage tanks, and fuel tanks. It can also be utilized in food-handling instruments such as cooking utensils, pots, ice cube traps, pans, and refrigerator panels. It is also employed in manufacturing construction products such as roofs, sidings, garage doors, insulation panels, gutters, and downspouts.

Aluminum 5005 makes an excellent construction material and is used in sidings, roofing, and furniture and as an electric conductor. Moreover, It is also utilized in chemical and food handling equipment, HVAC equipment, vessels, tanks, and high-strength foils. Due to its bright surface, it is helpful in decorative applications.

Aluminum 5083 is used in rail cars, pressure vessels, drilling rigs, shipbuilding, and vehicles.

Aluminum 5052 is used in ductile applications such as food processing equipment, cooking utensils, heat exchangers, and chemical storage tanks. Its application also includes truck panels, flooring panels, rivets, wires, treadplates, and containers.

Aluminum 6061 can be shaped into tubes, beams, and angles with rounded corners. They are used in tank fittings, trucks, railroad cars, marine components, pipelines, and furniture.

Aluminum 6063 is extensively used in architectural applications such as stair rails, furniture, window frames, doors, and sign frames. They can also be shaped into tubes, angles, beams, and channels.

Aluminum 6262 is used in screw machine products, hinge pins, marine fittings, pipeline fittings, knobs, nuts, couplings, valves, and decorative hardware.

Aluminum 7075 is preferably employed in aerospace and aircraft applications due to its high strength. It can also be used in producing engine parts, molds, competitive sporting equipment, and industrial tooling.

What are the different forms of Aluminum?

#1. Wires

Aluminum wires are produced by processing the aluminum ingots through a die that compresses the diameter of the ingot while increasing its length.

Aluminum has good electrical conductivity and a high strength-to-weight ratio, therefore they are used as an alternative to copper in electrical applications. However, aluminum wires used in this application can be oxidized easily.

If the measures to prevent the oxidation of wires are not taken, it can result in the deterioration of the electrical wiring and a potential fire hazard.

#2. Foils

Aluminum foils are manufactured using aluminum sheets. It undergoes a flattening process using a roll mill which reduces the thickness of aluminum sheets.

The range of thickness of aluminum foils is 0.2 mm to 6 microns. These are malleable, pliable, and can be easily bent and wrapped around objects.

They are also utilized as a packaging and electromagnetic shielding material along with other industrial applications.

#3. Sheets

Aluminum sheets are produced by applying high-pressure rolling operation on aluminum slabs several times until they are thinner and flatter. The aluminum sheets have a thickness of under 0.249 inches.

These are the most extensively used form of aluminum products. The application of aluminum sheets is to manufacture cans, packaging materials, truck, and automotive parts, cookware, and construction parts such as roofing, siding, and gutters.

#4. Plates

Aluminum plates are manufactured just like aluminum sheets, the only difference is that the thickness is above 0.250 inches.

As a result, they are more often used in heavy-duty applications. Applications of aluminum plates are in transportation, aerospace, aircraft, marine, and military industries. They are also utilized to manufacture storage tanks and fuel tanks.

#5. Bars, Tubes, and Pipes

Aluminum bars, tubes, and pipes are extremely important components manufactured using Aluminum. These are produced by an extrusion process, in which an aluminum billet is passed through the opening of a die by compressive force.

The die transforms the shape of the billet as it passes through.

The extrusion process is flexible and can produce a variety of parts with different cross-sectional shapes. The shapes produced can be round, rectangular, square, and hexagonal bars, as well as hollow tubes and pipes.

Moreover, it can be used to create parts with complex shapes and constant cross-sectional area. Aluminum bars, tubes, and pipes are used extensively in industries such as structural, aircraft, automotive, marine transportation, aerospace, and HVAC equipment components.

Internal Resources:

- Master Cylinder

- Cylinder Liner

- Automobile Classification

- Air Suspension System

- Flywheel Camshaft Crankshaft

- Clutch Complete Notes

- Single Plate Clutch

- Multi-Plate Clutch

- Drum Brake vs Disc Brake

- Battery Ignition System

- Magneto Ignition System

- Electronic Ignition System

- Lubrication System Types

Discussion about this post