A Combustion chamber is an important component of an Internal combustion engine. It plays a vital role in engine performance and its knock properties. In this article, we will study all the different types of combustion chambers and their uses in detail.

Note: The PDF file of every article you can download at the end of the aticles.

What is a Combustion Chamber?

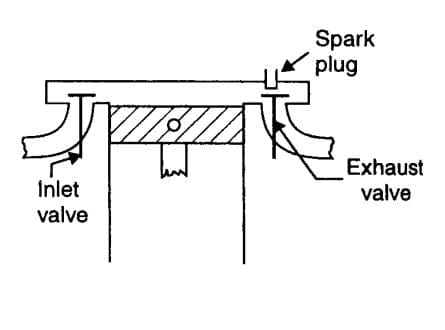

The volume in an internal combustion engine where the air-fuel mixture is ignited or burnt is called the combustion chamber.

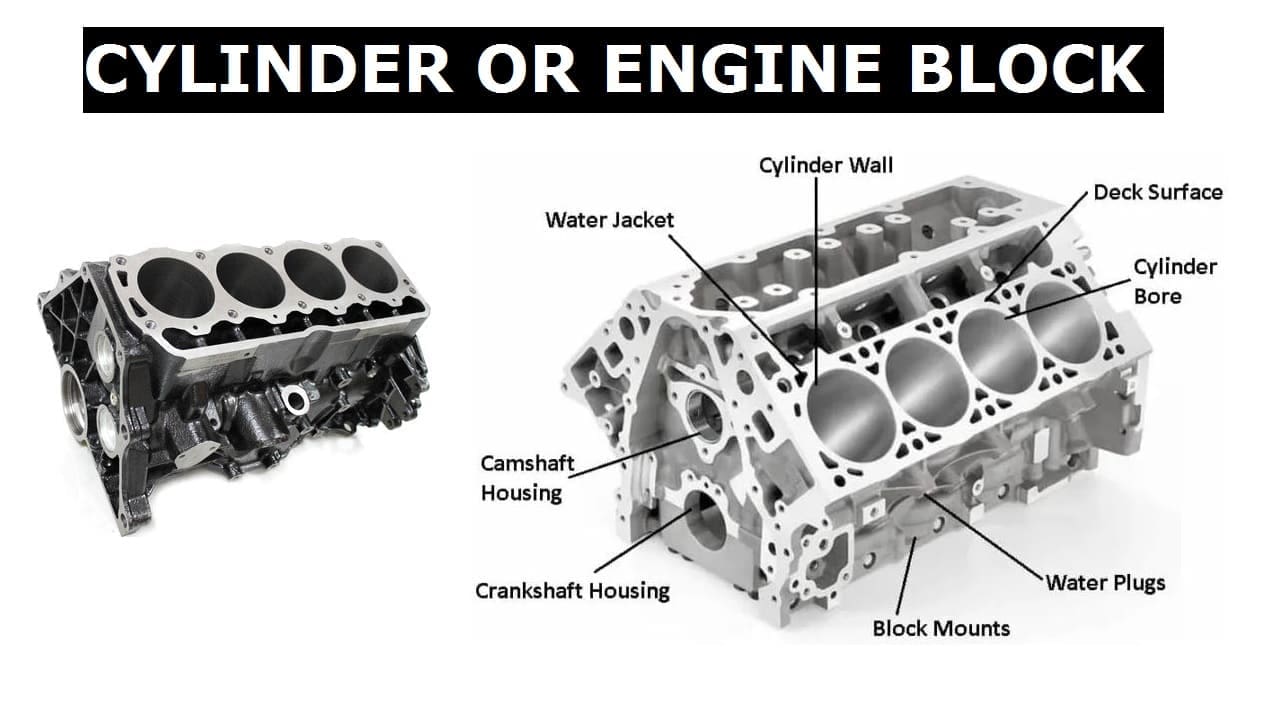

Typically, In an internal combustion engine, the combustion chamber is the volume between the piston head (at top dead center) and Cylinder head of the engine.

The piston compresses the air-fuel mixture in the combustion chamber and the charge is ignited to be pushed out of the combustion chamber of an IC engine. It may vary for different types of engines.

Requirement for Good Combustion Chamber:

These are the following requirement:

- A good combustion chamber can deliver high Power output and High thermal efficiency.

- Smooth Engine Operation

- Long Engine life

- Avoid knocking and detonation and

- Reduce exhaust pollutants.

What is Function of Combustion Chamber?

The following functions are:

- It accomodates the valve (Inlet and Outlet) for In & Out of mixtures.

- It houses and guide the Piston.

- There is confined space here in which the air and fuel mixtures are burnet.

- When the temeperature raise or decrease it has such properties to withstand it.

- It has made such shape that the proper combustion take place.

Different Types of Combustion Chamber:

The charge coming inside the engine and the cycle of operation in diesel and petrol engines are different. Hence there are two basic types of combustion chambers.

- Combustion chamber in Petrol engines and

- Combustion chamber in Diesel engines

Combustion chamber in Petrol Engine (Spark Ignition):

The petrol engine works on the otto cycle and the charge entering the engine is the mixture of fuel and air. The charge needs to be ignited by an external effort; therefore, the combustion chamber of a petrol engine consists of a spark plug.

Elements or construction of the combustion chamber in a Petrol Engine:

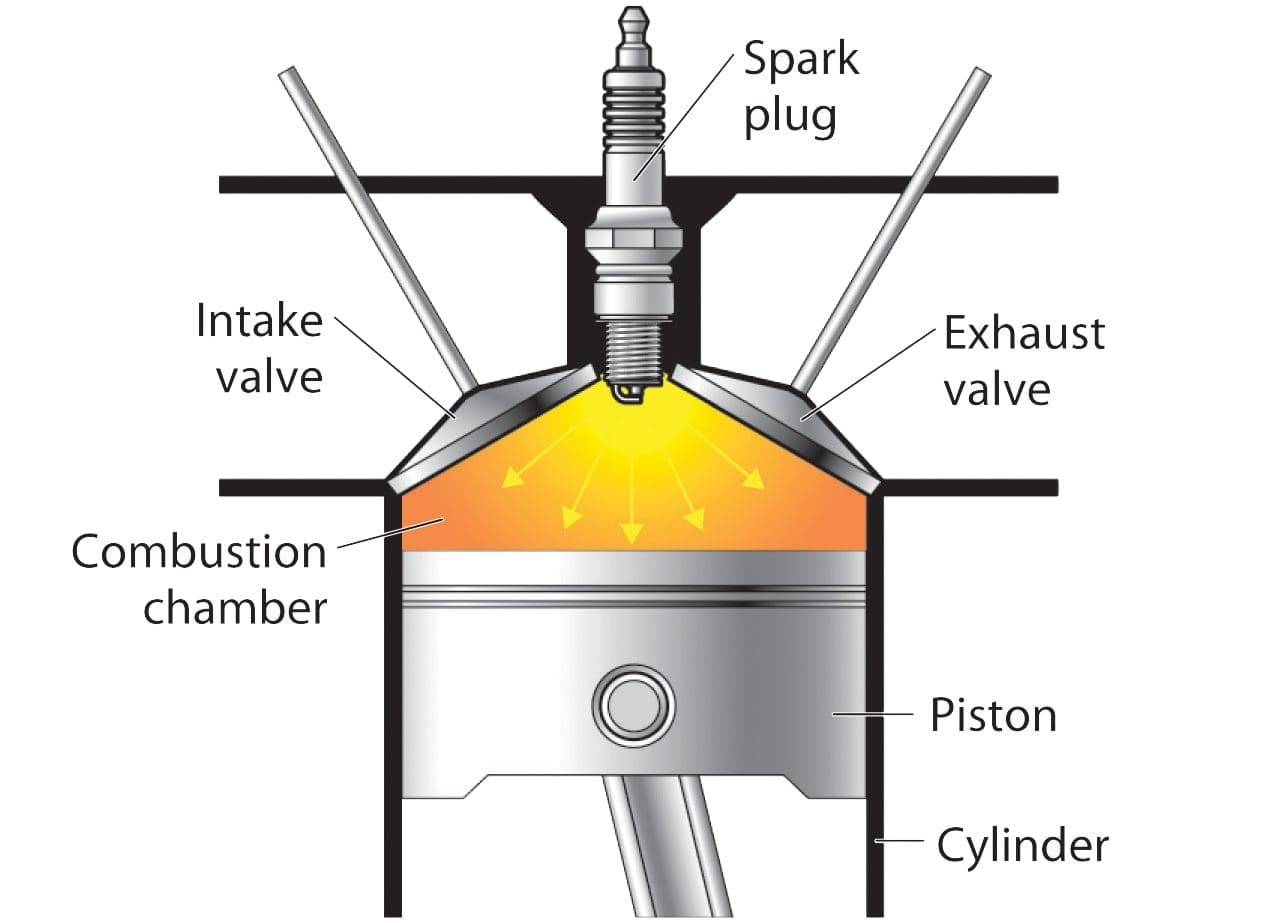

The basic diagram of a combustion chamber is given below.

Here the spark plug is situated on the top, the inlet valve on the left, and the outlet/exhaust valve on the right. The piston is in the top dead center position.

Inlet valve: The inlet valve is the valve from where the air-fuel mixture enters the combustion chamber. This air-fuel mixture comes from the carburetor. The inlet valve is operated by a camshaft.

Outlet valve: The outlet valve is the valve that allows the exhaust gases to vent out of the combustion chamber it is also operated by the camshaft.

Spark plug: As the name suggests a spark plug is a small part that creates a spark for the charge to ignite. The autoignition temperature of petrol is quite high that is why we need a spark plug to ignite the fuel to generate power out of it. The spark created by the spark engine is for a very short period but is enough to ignite the mixture.

Different Types of combustion chamber for Petrol Engine:

There are five types of combustion chambers used for petrol engines those are:

- Spherical shaped

- I-shaped

- T-shaped

- F-shaped and

- L-shaped Combustion chamber

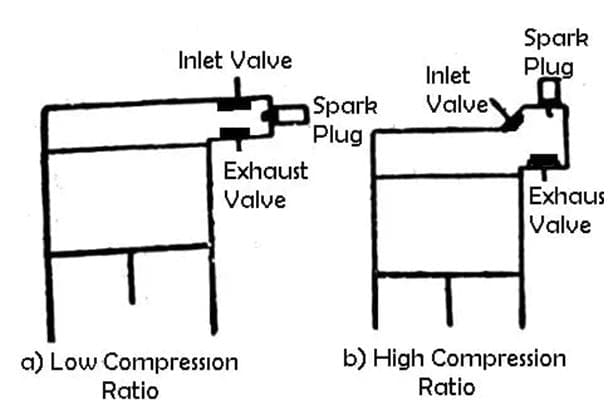

#1. Spherical Shaped Combustion Chambers:

The combustion chamber is almost hemisphere in shape, the engine possessing such combustion chambers is called a hemispherical engine. The inlet and the outlet valve of the engine are situated on the wall of the hemisphere.

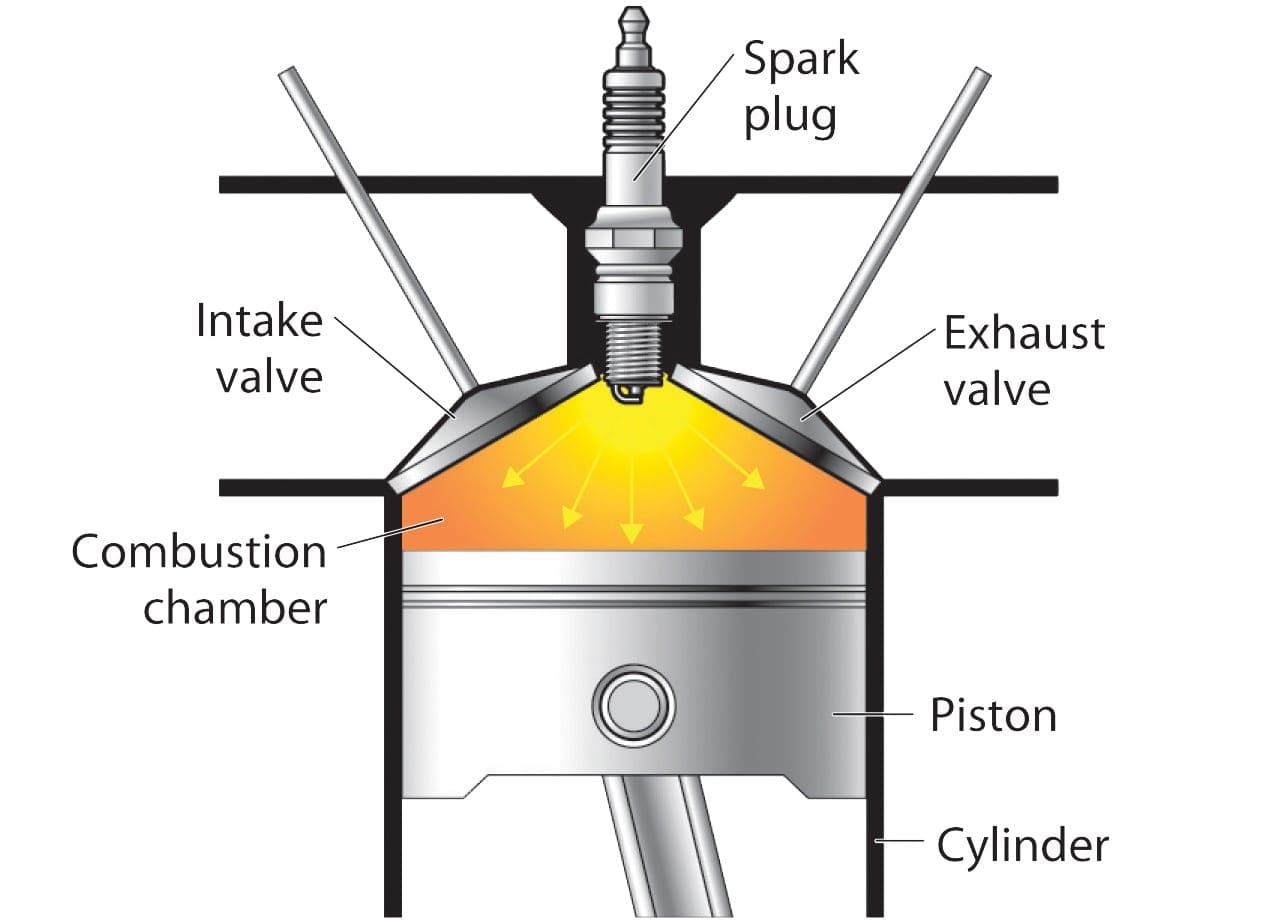

The situation of the spark plug may vary, when the spark plug is situated on the top it gives a high compression ratio and when the spark plug is situated on the side it gives a low compression ratio.

When the spark plug is situated on the side, the engine offers better scavenging. Generally, combustion chambers with a sparkplug situated on the top are used.

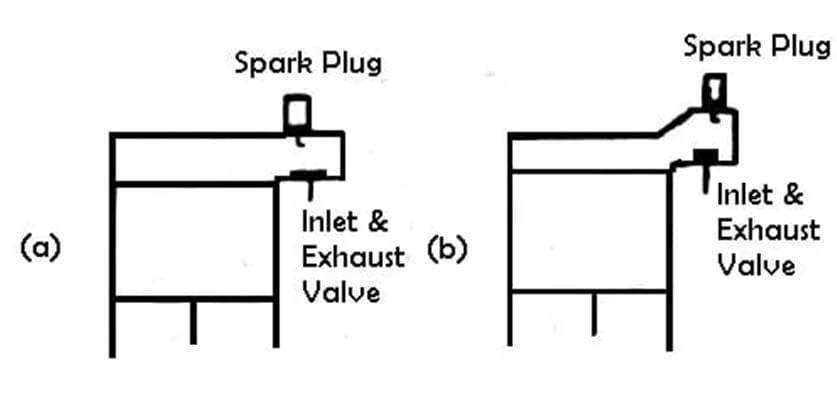

#2. I-shaped combustion chambers:

The I-shaped combustion chambers are used in vehicles that require high speed like racing cars. In these combustion chambers also the position of the spark plug may vary according to the requirement.

#3. T-shaped combustion chambers:

These types of combustion chambers provide high economy at moderate speeds. In the T-shaped combustion chambers, the spark plug is situated just above the exhaust valve.

#4. F-shaped combustion chamber:

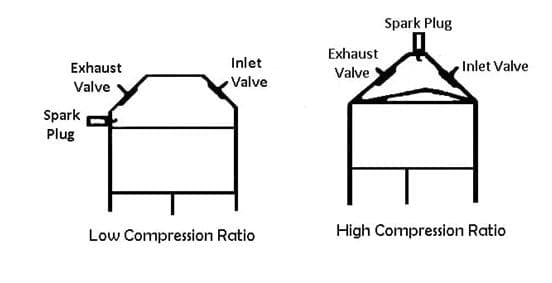

The F-shaped combustion chambers are extended from one side of the cylinder. The inlet valve, outlet valve, and sparkplug are generally located on the extended side of the combustion chamber.

#5. L-shaped combustion chamber:

The construction of L-shaped combustion chambers is similar to f shaped combustion chambers the only difference is that there is only one valve that functions like both intake and exhaust valves.

Combustion Chamber in Diesel Engine:

Unlike petrol engines diesel engines work on the diesel cycle, the fuel is burnt in constant pressure. The charge is ignited due to increased pressure inside the cylinder. The air comes from the intake manifold through an air filter and fuel comes from the fuel injector.

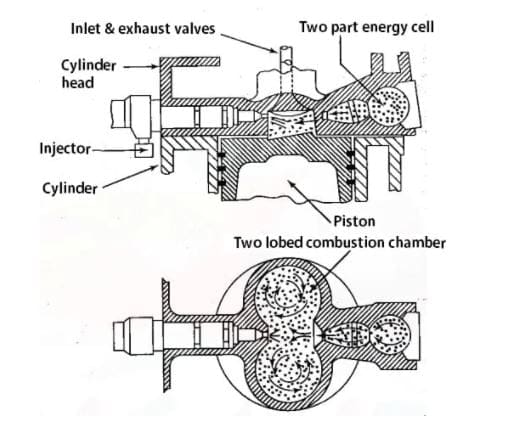

Elements of the combustion chamber in diesel engine:

Inlet valve: The inlet valves here are the same as the inlet valve used in a petrol engine the only difference is that only air enters through inlet valves instead of the air-fuel mixture.

Outlet valve: The outlet valve allows the exhaust gases to go out of the cylinder. In the case of diesel engines, the exhaust valves have to face much more carbon deposits.

Fuel injector: A separate fuel injector is present in diesel engines that sprays the fuel at the correct timing. The fuel injector is provided with a nozzle so that it should evenly sprinkle the fuel. This fuel mixes with the inlet air coming through the intake manifold.

Different Types of Combustion chamber for Diesel Engine:

There are 5 types of combustion chambers used in diesel engines

- Open combustion chamber

- Pre-combustion chamber

- Swirl combustion chamber

- Squish combustion chamber and

- Air-cell combustion chamber.

#1. Open combustion chamber:

The main identification of an open combustion chamber is that it has a groove on the piston head. These types of chambers are used for moderate and high-speed applications. The fuel injector is situated on the top of the chamber for even distribution of diesel.

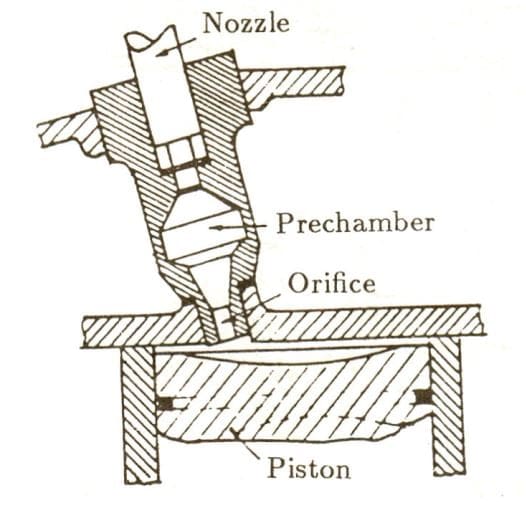

#2. Pre-combustion chamber:

A pre-combustion chamber is a special type of combustion chamber that is used for high-speed applications. In this type of combustion chamber there are two combustion chambers one is the auxiliary combustion chamber or pre-combustion chamber and the other is the main combustion chamber.

The fuel injector is located on the top of the pre-combustion chamber. A glow plug is also provided in the auxiliary combustion chamber, with the help of which the fuel is party burnt and this part burnt fuel reaches the main combustion chamber where the fuel is completely burnt. It helps in creating turbulence for the fuel.

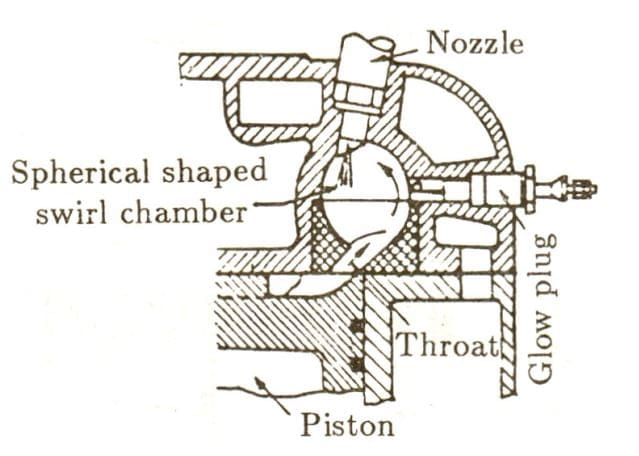

#3. Swirl combustion chamber:

As the name suggests swirl is a kind of circular motion given to any fluid. In this type of combustion chamber, the incoming air is given a swirl during the suction stroke and the fuel is injected into the swirling air. This helps in better mixing of air and fuel and results in the complete burning of the fuel.

#4. Squish combustion chamber:

In a squish combustion chamber, the air coming Inside the cylinder is made to push towards the center of the cylinder right below the spark plug. This is done with the help of a special groove made on the cylinder head. The turbulence created helps in better mixing of fuel and air which results in the complete burning of the charge.

#5. Air-cell combustion chamber:

In the air-cell combustion chamber, a separate air cell is provided which is used to blow air in the main combustion chamber. When the compression stroke takes place, the air is compressed in the air cell and its temperature is increased.

When the piston moves towards BDC the hot air from the air cell enters the main combustion chamber which allows the fuel to burn completely.

Advantages of combustion chamber:

- The entire engine operations are carried out inside a single frame.

- The cost of a separate assembly is saved.

- Reduces complexities and efforts.

- Promotes maximum burning of fuel.

- Energy wastage is less.

Disadvantages of combustion chambe:

- The heating of cylinder walls takes place.

- More carbon deposits.

- Cold starting the engine is difficult.

So here our topic ends. Let me know what more I can contribute to this? and I have more articles for you to read, you can check that too.

If this article helps you then do not hesitate to share it with your needy one. Thank you for your valuable time.

Internal Resources:

- Lubrication System Types

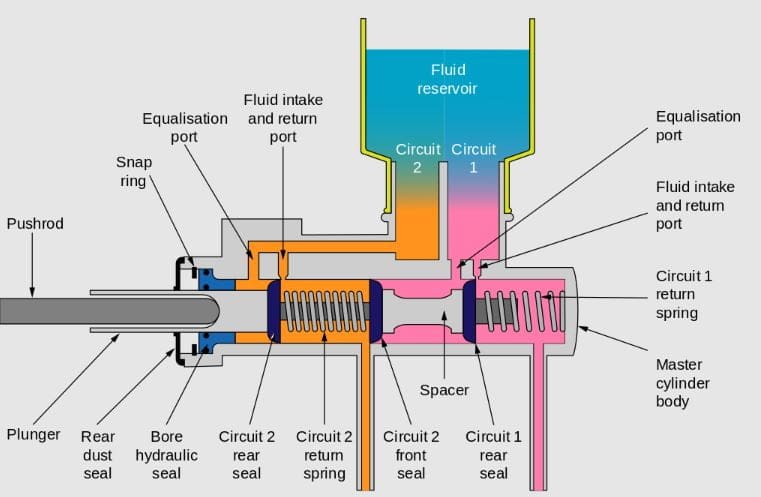

- Braking System Types

- Magneto Ignition System

- Battery Ignition System

- Single Plate Clutch

- Multi-Plate Clutch

- Flywheel

- Camshaft

- Propeller Shaft

- Crankshaft

- Clutch complete Notes

- Electronic Ignition System

Discussion about this post