What is a Screw?

A screw is a type of fastener used to join two or more moving or stationary parts to provide a tight fit between those parts.

Unlike bolts, It does not require nuts to get fastened it can directly join two parts.

This can be fixed into a predrilled or solid surface depending on the type of screw and the surface hardness.

It can be fastened or loosened by various tools such as screwdrivers, spanners, Allen key, or simply by hand.

History:

Greek Mathematician Archytas was the first one to describe a screw (428-350BC). In the 1st century, BC Wooden screws were commonly used for removing oil from olives and for crushing grapes to produce wine.

Metals screws were uncommon in Europe till the 15th century. It was in the late 1700s when machines began to develop the use of screws as fasteners also became common.

Currently, if we observe things around us, we can find screws everywhere right from our TV remotes to the handles of our cooking vessels.

Screw Geometry:

The basic geometry is given below.

Screws Head:

The screw head is the topmost part of the screw. Generally, the diameter of the head is the greatest diameter of the screw.

This is tightened or loosened by any tool fixed in the head of the screw.

Body:

The part below the screw’s head is called the body of the screw. It is that part that gets penetrated into the object. The body consists of helical structures called threads of the screw.

The diameter of the body without and with considering the threads is called minimum diameter and maximum diameter respectively.

Threads:

Threads are the most important feature of the screws. They are helical structures around the cross-section of the body.

Threads are responsible to change the rotational motion of the screw into vertical push or pull with respect to the object. The distance between each consecutive thread is called a pitch.

A pitch is defined as the length of the screw that will penetrate the hole in one full rotation of the same screw. Threads provide easy motion inside or outside the objects.

What are Different Types of Screw?

The following different types are as follows:

#1. Flathead screws:

Flathead screws are the type of countersunk screws. The top of the screw is flat with a drive on it. These screw heads are generally tapered to penetrate into the object.

The main advantage of flathead, screws are, that nothing or very little part of the screw head is visible above the surface of the object.

Therefore, these screws are used where no part of the screw should come above the surface.

Flatheads are generally made of stainless steel or zinc coating and are generally used in ceiling lights, where aesthetics is considered important.

#2. Oval Head Screw:

The oval head is also a type of countersunk screw. It has great decorative importance due to its round symmetric head.

It also has a tapered cross-section for easy penetration of the head. These are also made of stainless steel with good corrosion resistance.

The oval head fits just above the surface to be fastened and provides an aesthetic finish.

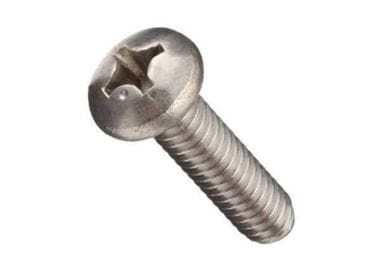

#3. Pan Head screw:

Pan’s heads are non-countersunk types of screws with a flat surface touching the object. They are used to fasten machine parts together. They have wide chamfered heads with drives on them.

Pan’s heads have great importance in automobile industries, they are used to secure headlights, number plates, and various other components.

The head remains over the surface to be fastened. Pan head screws are one of the most common types of screws.

#4. Truss Head Screw:

Truss head screws are non-countersunk types of screws with an extra-wide and rounded surface.

The difference between the pan head and truss head is the area of the truss head is more than that of the pan head for the same length of the screw.

A truss head is also known as a mushroom head screw.

#5. Roundhead Screw:

Roundhead screws are also non-countersunk types of screws. It is much similar to that of a truss head screw.

The only difference between the round head and truss head is that the area of round head screws is less than that of the truss head screws.

#6. Hex Head Screw:

Hex head simply refers to a hexagonal-shaped head that looks similar to a bolt and It is another type of non-countersunk screw that is used to secure two or more metallic parts to provide a tight fit.

It can be driven with the help of a spanner and has two more variations.

It may have a washer attached to it for providing a large surface area to hold the mating parts better, this is called a hex washer.

Another variation consists of a washer attached and the head is slotted. This can be driven with a spanner as well as a screwdriver and is known as a slotted hex washer.

#7. Socket Cap Head:

A socket cap head is a different type of non-countersunk screw that is shaped like a barrel with a hexagonal slot in the middle of the barrel-shaped head.

It is a type of machine screw generally used to clamp machine parts. An Allen key is required to drive such types of screws.

#8. Slotted Drive Screw:

A slotted drive is a single and straight notch-like structure on the head of the screw. The screwdriver makes two-point contact with the screw head.

There are chances of slipping in case of a slotted drive. These are generally used for installation purposes and carpentry work.

The torque transmission is not very easy in the case of slotted drive hence these are used where minimum torque is required.

A wedged-shaped screwdriver is used to drive the screw. The slotted drive was first manufactured in the year 1950.

#9. Phillips drive Screw:

Phillips drive was invented and patented by Henry Philips in the year 1930.

Unlike the slotted head screw, a Phillips’s head provides four-point contact to the screwdriver which in turn provides a better torque transmission to the screw. It uses a Phillips screwdriver to drive such types of screws.

A Phillips’s head provides a tighter fit than the slotted head. Phillips drive screws are comparatively smaller and lighter.

They are used to secure parts related to a power tool. Hundreds of the Phillips drive screws are used in various automobile.

#10. Combination drive Screw:

As the name suggests a combination drive is a mixture of Phillips and slotted drive. It has two mutually perpendicular slots one small and the other touching the circumference of the head.

These slots intersect each other at the center of the head. These are designed to be engaged with Phillips as well as wedged screwdrivers.

They have various applications which cover the applications of both slotted head and Phillips head.

#11. Socket drive Screw:

Socket drives are also known as hex or Allen drives which can be driven by an Allen key. These have an internal hexagonal slot for the Allen key to fit in. These are most commonly used for securing machine parts or moving parts.

#12. One-way drive:

The one-way drive is a unique type of screw, it is also known as safety screws or security screws. They are most commonly used for safety gates and clamping something in public.

The unique feature of such drives is that it enables easy fastening but a difficult loosening of the screw.

They have drives designed in such a way that during loosening the driver slips away from the screw head making it difficult to unclamp the object.

#13. Square drive:

Square drives are also known as Robertson or Scrulox screws, these have a square-shaped slot that is slightly tapered. These screws provide a better grip on the driver.

The driver is also tapered slightly won enables a quick fit with the drive. These are used where better torque transmission is required.

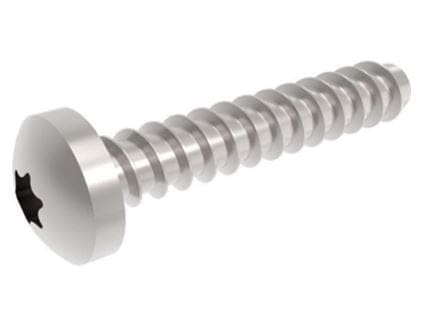

#14. Torx Screw:-

A Torx screw has a 6-point star-shaped slot on the head of the screw. It enables 6-point contact with the screwdriver hence resulting in excellent torque transmission.

This was first developed in 1967. It is a better replacement for a socket drive as the chances of slip become minimum.

#15. Wood Screw:

Wood screws are generally used for clamping wooden pieces together although they can be used to clamp metal as well.

These screws have sharp threads with a small pitch for better insertion on the wooden surface. These screws are made of steel, aluminum, or brass.

The structure of the screw consists of a head, a shank, and a threaded body. The purpose of the shank is quite complex. If there is no shank and the screw is drilled into the workpieces then it will clamp the two workpieces.

But if the operator needs a tight fit and rotates the screw, it will push the head of the screw into the surface of the upper workpiece and will damage it.

Hence a shank is provided so that the surface remains unharmed and a tight fit is also provided by pulling the lower surface by the threads.

The shank also reduces the friction produced by the threads.

#16. Machine Screw:

As the name suggests a machine screw is used to clamp two metallic parts of a machine or any heavy product.

It is made of stainless steel and has high toughness. These are a bit smaller than other screws.

The structure of the machine screws consists of a head and threaded body. These are available in different types of heads and drives.

In a machine, one can have short as well as long pitches. Unlike other screws, machine screws have blunt ends.

Therefore, machine screws are generally used for pre-drilled holes. Machine screws are often used to clamp more than two parts together.

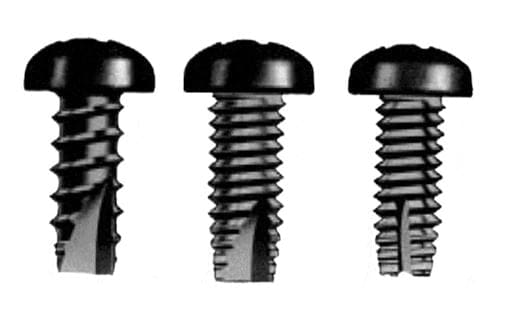

#17. Thread Cutting Screw:

A thread-cutting screw is a type that cuts its own threads as it progresses further.

The structure of thread-cutting screws may differ according to The application but one common feature is that it has some notches in the end which helps in creating threads.

A thread cutting screw is used where there is a need to unclamp the workpiece for regular servicing.

#18. Sheet Metal Screw:

A sheet metal screw is often used for sheet metal applications. It can also be used to join two metallic parts together.

These screws are also used to join two dissimilar materials together. Sheet metal screws are generally very sharp at the end and are fully threaded.

These are available with different heads and drive types. Sheet metal screws are made of stainless steel. The screws are resistant to corrosion and highly durable.

#19. Self-Drilling Screw:

It is evident from the name that the screw which can drill its hole is called a self-drilling screw.

A self-drilling screw can be identified very easily as it has an end that looks like a drill bit. The end of the screw is provided with multiple cutting edges to drill into the material and remove the chips from the hole.

The end is followed by sharp cutting threads which make helical grooves on the inner surface of the hole. Self-drilling screws are available with various heads.

A typical self-drilling screw is made of stainless steel. These are time-saving screws as there is no need for a predrilled hole. These can be used to clamp metal to metal or metal to wood.

#20. Set screw:

A set screw also known as a grub screw is a headless screw generally used to clamp two moving parts.

It is threaded along its entire length with a uniform cross-section. Set screws can be made of a variety of materials such as plastic, nylon, aluminum, copper, stainless steel, or titanium.

These are used when there is no place for the head of the screws.

#21. Eye Screw:

Eye screws are mostly used on the wall, they are fastened into a predrilled hole and are used to pull cables through them.

They have a threaded shank and the head is a round eye-like structure through which a cable or a rope can be pulled.

Another variation of an eye screw is a hook screw which has a hook-like structure instead of an eye. A hook is used to hang the objects.

#22. Mating Screw:

The mating is a special type of screw that comes in a pair with the bolt. The bolt is internally threaded for a mating screw to fix in. these are used for binding two objects together, with heads attached on both sides.

Discussion about this post