Forging tools are the equipment used in the Forging Industry (Manufacturing Industry) for several purposes which I will explain in detail one by one.

Forging is a process in which we change the shape and size of material into another form that we required. The hot forging is done at a very high temperature and the cold forging is done at room temperature.

In forging we use Hammer for striking the workpiece so that the shape and size can be changed.

What is Forging?

Forging is a manufacturing process carried out by heating a metal part in an open fire (using Anvil) at an elevated temperature and striking it by using a blacksmith to deform it completely into another shape.

When it comes to forging tools, we use appropriate tools for good forged work.

There are different types of forging tools used for different forging operations. Nowadays modern forging is highly automated, made of a high-tech machine which saves much time and made little easy works for blacksmiths.

Different Types of Forging Tools and their Uses:

There are the following Forging Tools given below:

- Tongs

- Rivet Header

- Anvil

- Furnace or Hearth

- Chisel

- Fuller

- Hammer

- Punch

- Drift

- Flatter

- Swage

- Swage Block

- Set Hammer

- Clamping Vice

- Black Iron

- Forging Dies and

- Press

All the forging tools we will study one by one in detail. So let’s start with the Tongs first,

#1. Tongs:

Tongs are a tool used for adequate gripping (Holding) the different shapes and sizes of the heated workpiece. With the help of tongs, we shift the workpiece to another place (From furnace to anvil).

The material used for tongs is mild steel which has 29 percent of carbon.

There are four different types of tongs used in the forging operation. The names are Flat tongs, Straight lip fluted tongs, Rivet or ring tongs,s and Gad Tongs.

- The flat tongs are used for gripping the rectangular types of workpiece.

- Straight lip fluted tongs is Used for gripping the square, circular and hexagonal shaped types of workpiece.

- The rivet tongs used for holding bolts, rivets types.

- And Gad tongs is used for gripping general pick-up workpiece, it may be straight or in any form.

#2. Rivet Header:

The rivet header tool is used for producing rivet heads on the workpiece. In simple we can say to make a hole we can use a rivet header.

#3. Anvil:

Anvil is one of the most important parts of the forging industry. It is made up of Steel (Material). Anvils serve as a workbench for blacksmiths.

On the anvil with the use of a hammer, we perform different operations like flatting metal surfaces and obtaining shapes of workpiece.

There is some anvil which has Hardy holes and Punches hole. The hardy hole helps to do square shank for hardy and the punch hole provides clearance for punching hole in the workpiece. This is one of the major advantages of having Hardy and Punches holes.

In forging the average weight of an anvil is 100 kg to 150 kg and Anvil’s top face should stand about 0.75 mt. from the base.

#4. Furnace or Hearth:

The furnace is also known as Hearth. It has four legs for support and body material is either steel or cast iron, Iron bottom, a chimney, and a blower. In the furnace, we used to heat the workpiece.

#5. Chisel:

It is used for cutting the workpiece. There are two types of chisel: Hot chisel and cold chisel. The hot chisel is used for cutting hot workpieces (Hot forging) and cold is used for cutting cold workpieces (Cold forging). Normally A hot chisel is preferred in a forging shop.

The difference between Hot and cold chisels is the edges of the cold chisels are at an angle of 60 degrees and Hot chisels at an angle of 30 degrees. In cold chisel, hardening and tempering are required whereas In hot only tempering is required.

The chisel is made up of high petroleum steel with an octagonal cross-section with a tapered cutting edge on one end for efficient cutting action.

6. Fuller:

The fuller is used to form metal when hot. The fuller tool comes in different shapes and sizes according to requirements. When the workpiece is hot, applying compressive load spreads the metal.

The fuller is round-shaped face spreads metal more efficiently and easily in comparison to a flat surface of the hammer.

#7. Hammer:

In general, Hammer is a tool used for striking the workpiece. We have seen hammers in several places for several works. But forging Hammer is having more weight to perform several operations like hot forging, cold forging, press forging, closed die forging, upset forging, and so on.

The hammer has a heavy head fixed with a long handle which gives a high impact load on the small area of the workpiece. It is used for striking the hot or cold workpiece to change shape and size as needed.

The different types of Hammer are Drop Hammer, Power Hammer, Hand Hammer, and Sledge Hammer.

Drop Hammer: A heavy ram is falling onto the Workpiece by gravity.

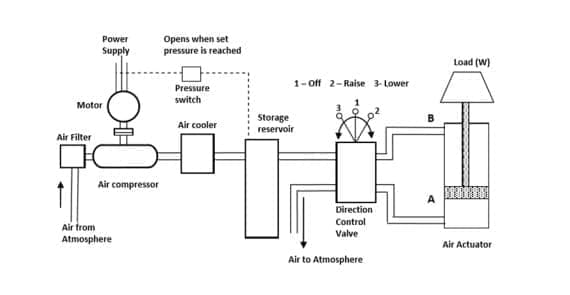

Power Hammer: The power hammer in which the power source is from compressed air, Hydraulic or electricity in driving the hammer into the workpiece. We use this type of hammer for larger jobs.

Hand Hammer: The hand hammer is used by blacksmiths. The other types of Hand hammers are Ball peen, Straight peen, and Cross peen hammers.

Sledge Hammer: The sledgehammer used in striking on the workpiece by a driver and is heavier to hold by smith’s hand. The different types are Double face, Straight peen, and Cross peen hammer.

#8. Punch:

The punch is made up of high carbon steel which is used for making a hot hole in the workpiece. The punch comes in different sizes. When we want to make a hole on the workpiece simply keep the thinner part on the hot metal and apply compressive load by hammering into it.

The punch are two types one is Dot punch and the second one is center punch. Dot Punch: It has an angle of a tip about 60 degrees and Centre punch: It has an angle of a tip about 90 degrees.

#9. Drift:

Drift is a kind of tapered rod made up of steel and is used for enlarging the holes of the workpiece. It is not used as a punch; it helps to remove dents from inaccessible places. Drift has a small diameter in comparison to hammer face.

#10. Flatter:

Flatter is a tool used for flattening or leveling the hot surface of the metal with the use of hammering. The flatter consists of a plain face with a straight shank.

The plane face is attached at a lower end of flatter and a Straight shank is attached above the plane face. The lower end which is the plane face is placed on the workpiece and the use of the hammer is when we strike to upper part which is a straight shank so that the workpiece can get flattened. Another use of flatter is finishing corners and edges of the hot Workpiece.

#11. Swage:

Swage is made up of high carbon steel. It gives various shapes to the workpiece like round, square, or hexagonal form. The swage has handled at the top and at the bottom, there is a square shank.

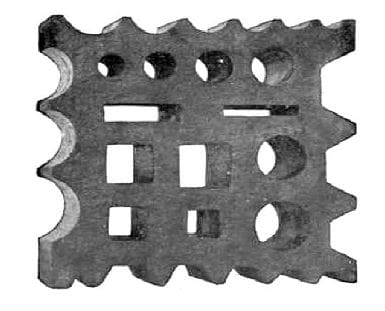

#12. Swage Block:

A swage block is a square or rectangular block made up of cast iron or steel and it has several holes in it. The holes present in the swage block are of different shapes and sizes.

It is used to perform several operations like sizzling, heading, squaring, bending, and forming in forging.

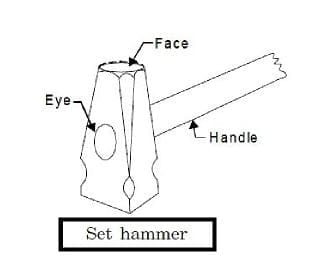

#13. Set Hammer:

Set hammer is a similar tool to flatter but it improves the efficiency of the workpiece as done by flatter. It works to make a workpiece surface plane. The set hammer is made up of steel.

To use the set hammer the workpiece must be placed at the anvil to use it. The set hammer provides good and smooth surfaces to the workpiece.

#14. Clamping Vice:

Clamping vice is another most important tool and it is used for holding workpieces. It consists of two jaws, a spring, and a flat bottom. The workpieces are placed and clamped between two jaws and tightened to hold them tightly.

#15. Black Iron:

The black iron is a tapered tail at one side and the other side is similar to the horn of an anvil. It is made up of steel and is hardened. It is a type of anvil we can say because of the tapered tail. Here we do small types of work.

#16. Forging Dies:

Forging dies is required to properly mold metal. With the help of forging die the malleable metals are pressed. It is used for heavy jobs and large production.

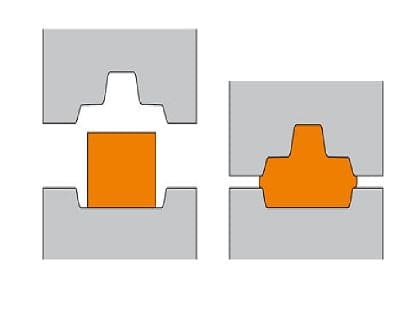

The forging dies are very important for different operations. There are commonly two operations Open Die forging and Closed die forging.

Open Die Forging: Open die forging in which there is no such die used to encase the metal and provide free flow everywhere except the metal meets the die. It is used for very large parts jobs. In open die forging the blacksmiths do not use tangs to grip the workpiece, It is held by other heavy tools.

Closed Die Forging: Here there is a die that works is to encased the metal when hammered or pressed against the workpiece, The workpiece metal flows and fills the cavity because the metal is at maximum temperature.

#17. Press:

Press is another type of tool used for providing excessive pressure to the metal to get desired shape and size. The major advantage of this is that it can be forged once the entire product.

The press is available in two types: Mechanical Press and Hydraulic Press Forging.

Mechanical Press Forging: The mechanical press forging is equipped with engine parts like a motor, crank, flywheel, and so on. The forging forces the ram against the workpiece. The system of forging is intended for small job workpieces. It is not suitable for larger workpieces.

Hydraulic Press Forging: The hydraulic forging operation is done by high-pressure fluids with the use of hydraulic pumps. The pressure created forces ram against the workpiece. The hydraulic forging is suited for larger workpieces.

Internal Resources for You:

- Forming Process

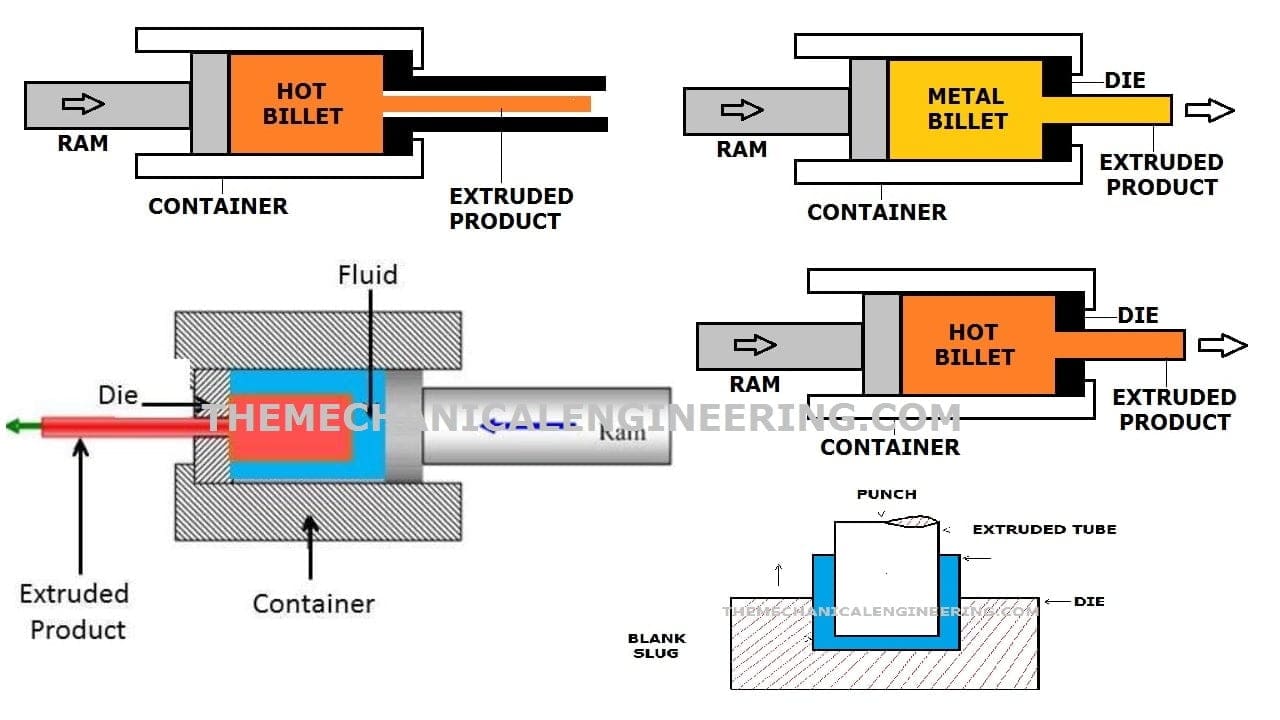

- Extrusion Process

- Types of Pliers

- Wrenche Types in detail

- Braking System in Automobile

- Types of Valve

- Screwdriver Types in detail

- Different Types of Lubrication System

- Lathe Machine

Reference [External Links]:

- https://ecoursesonline.iasri.res.in/mod/page/view.php?id=3795

- https://en.wikipedia.org/wiki/Forging

- https://www.forging.org/about

So here our topic ends. Let me know what more I can contribute to this and I have more articles for you to read, you can check that too.

If this article helps you then do not hesitate to share it with your needy one. Thank you for your valuable time.

Discussion about this post