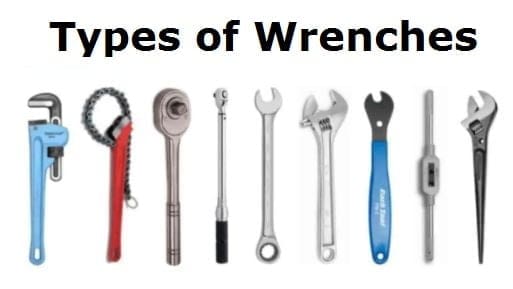

In this article, you are going to learn all the different types of wrenches in detail. Here I have mentioned wrenches subgroups to give you a better idea of the types of wrenches.

Before moving to further explain in detail let’s understand some basic point that helps you to understand all the wrench in detail.

Wrench Classification:

The subgroups have been categorized into three terms:

- Keys

- Socket and

- Spanner

Keys: These are specific types of wrenches often including hex keys, bottles opener, window cranks, Allen keys, etc. This has specified use for a particular work and it has hexagonal cross-sections to open different types of screws.

Sockets: These wrenches have a diverse set of sockets of various size nuts and bolts. You can easily connect these sockets with a handle. These sockets fit over the nut or bolts and loosen or tighten it.

Spanner: These wrenches are used to turn nuts and bolts having teeth, pins, or hook on their head. British English commonly uses this term instead of a wrench.

Now moving to our main topic which is wrenches Types. Let’s dive into our main topic,

Types of Wrenches:

There are forty-two (42) different types of Wrenches:

- Adjustable Wrench

- Allen Wrench

- Box-Ended Wrench

- Combination Wrench

- Crowfoot Wrench

- Impact Wrench

- Lug Wrench

- Oil Filter Wrench

- Open-Ended Wrench

- Pipe Wrench

- Ratcheting Wrench

- Socket Wrench

- Torque wrench

- Alligator Wrench

- Armorer’s Wrench

- Basin Wrench

- Bionic Wrench

- Bung Wrench

- Cone Wrench

- Die Stock Holder Wrench

- Dog Bone Wrench

- Drum Key

- Fan Clutch Wrench

- Fire Hydrant Wrench

- Flare Nut Wrench

- Garbage Disposal Wrench

- Hammer Wrench

- Monkey Wrench

- Pedal Wrench

- Pliers Wrench

- Plumber’s Wrench

- Spanner Wrench

- Spark Plug Wrench

- Spoke Wrench

- Spud Wrench

- Strap Wrench

- Stubby Wrench

- Tap Wrench

- Tension Wrench

- Torx Key

- Dental Key and

- Chunk Key

Now we will read one by one in detail.

#1. Adjustable Wrench:

An adjustable wrench is a most common and widely used wrench because of its adaptability. Its also known as a crescent wrench because of its adjustable crescent-shaped head.

In British English, it is also known as shifting spanner wrench. They have an adjustable open head in the crescent shape with the screw installed that opens or closes the crest as you rotate the screw.

An adjustable wrench can perform all the functions of the fixed wrench and, you don’t need to carry a set of dozens of sizes as this single wrench can work for all different sizes.

It requires more space compared to fixed wrenches as it is thicker in size. You might have seen plumbers, mechanics, and carpenters using these wrenches.

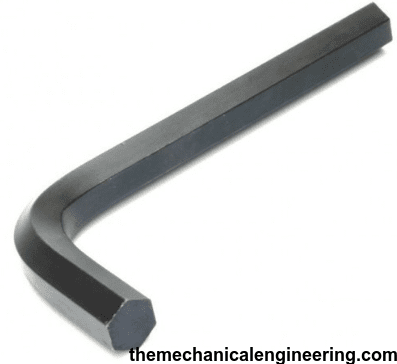

#2. Allen Wrench:

Allen wrench is generally T-Shaped or L-Shaped hexagonal wrenches that fit into the head of screws and bolts that have a hexagonal hole and recesses at the end.

It’s also called Allen key in British English. You might get this kind of key when you order any type of furniture online.

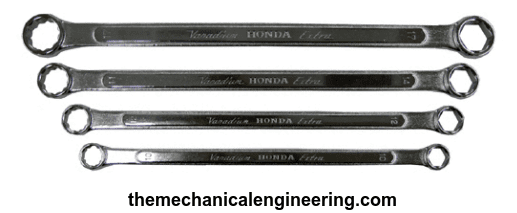

#3. Box-Ended Wrench:

Box-ended wrench comes with closed loops at the end where each end is either higher or lower than the handle. It is also known as ring spanner in British English.

The open-loop at the end of the wrenches fits on the head of the nut or bolt for operating.

It is either used in hexagonal or square shape nuts and bolts and comes in various sizes. Box-ended wrenches are usually sold in kits.

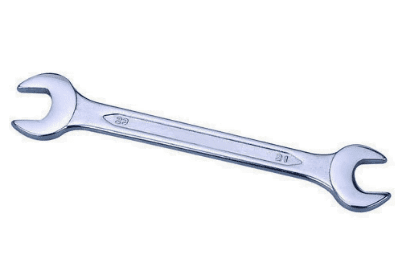

#4. Open-Ended Wrench:

Open-ended wrenches are the most widely used among all wrenches, and you will find them in all toolboxes because you can use these on hard-to-reach nuts and bolts, and because of their open design, they can be connected to the head of nuts or bolts vertically or horizontally.

It is also known as an open-ended spanner in British English. The only negative side of these wrenches is that they can round the corners of the bolt than other alternatives available.

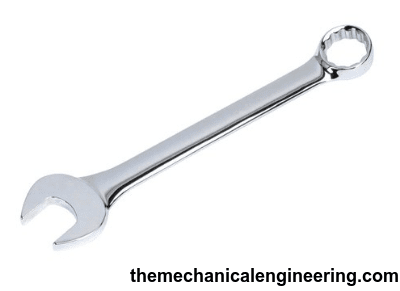

#5. Combination Wrench:

As the name infers, Combination wrenches are the combination of open-ended and box-ended. Where one end is a u-shaped open-end and, another is a closed-loop for hexagonal nuts.

It is also known as a combination spanner in British English. Used often in complex nuts where the closed-loop is used to loosen the nut and open end is used to unscrew it.

Combination wrenches come in sets that include multiple wrenches of different sizes.

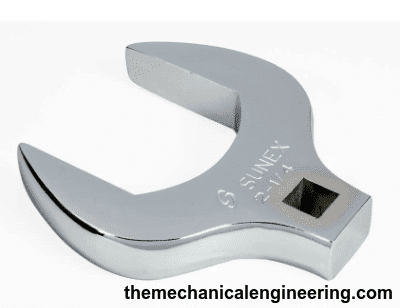

#6. Crowfoot Wrenches:

The Crowfoot wrench is the crescent head without a handle. This is connected to ratchet and socket extension. This allows fixing this wrench in the most complex places with compact spaces.

The Crowfoot wrench is widely used to handle bolts located in more difficult places in the machine frame without separating nearby parts.

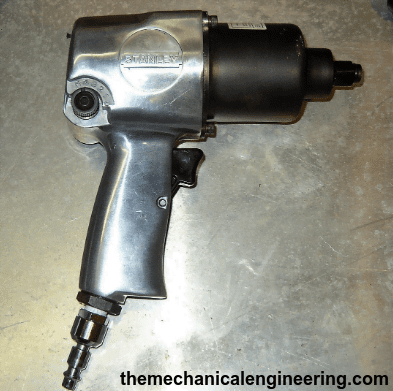

#7. Impact Wrench:

This is two types one is air impact wrenches which use an air compressor to function and another is cordless impact wrenches which use batteries to function.

An impact wrench is sometimes also called airguns or air wrenches. You might have seen these wrenches in an auto repair shop.

It is best suited for removing stubborn nuts and bolts because these can unscrew bolts by applying a high toque.

These are best suited for repetitive works like mounting the wheel of the car not suited for nuts that need accuracy.

It’s not recommended to use it for general use because it can damage the nuts and bolts thread by applying over-torque.

#8. Lug Wrench:

A lug wrench is known by multiple names because of its use and design. They are known as wheel braces because they are used to tighten or loosen nuts on a car.

This is also named as L-Shaped, which has two ends with two sockets of different sizes, and X-Shaped, which has four ends with four different sized sockets it is also known as spider wrench.

Longer lug wrenches generate more torque when applying force to loosen or tighten the bolts. In British English, it is often known as a tire spanner.

#9. Oil Filter Wrench:

Oil filter wrenches are generally used in the automotive industry to remove the cylindrical oil filter. It has four different types often depending on the brand of car.

This can be either chain type or strap type that uses the loop to wrap throughout the filter casing, and another can be claw wrench works similarly like the adjustable wrenches and also known as a chain wrench in British English.

#10. Pipe Wrench:

The pipe wrench is similar to the adjustable wrench with the stronger F- Shaped design.

It is used mainly on metal pipes and fitting by plumbers. It consists of jaws or teeth structures on its head that easily grip the pipes and fittings.

These teeth can also leave a scratch on these pipes. The adjustable jaw can be fixed according to the diameter of the pipe or the fitting by rotating the nut on the wrench.

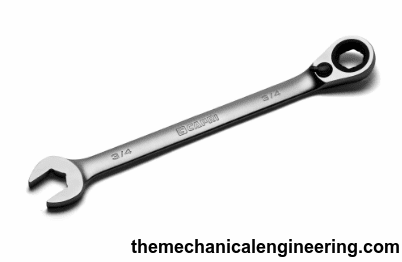

#11. Ratcheting Wrench:

A ratcheting wrench similar to a combination wrench but the main difference is it has a ratcheting device inside one end that helps to loosen or tighten the nut or bolt without removing the wrench or readjusting the position of the wrench.

This helps to work in the compact area easier. It is known as a ratcheting handle in British English.

#12. Socket Wrench:

The socket wrench uses a ratcheting mechanism to loosen or tighten any nut or bolt without lifting the wrench. It has multiple sockets according to the size of nuts and bolts.

You can easily improve your speed with the help of this wrench as it does not needs any adjusting of the wrench.

And if while performing loosening or tightening function you find any hindrance you can reverse the direction so that you get some space and continue working.

#13. Torque Wrench:

The torque wrench is specifically used to regulate and apply a precise amount of torque to nuts or bolts. It is the primary tool in automobiles, mechanics, wheel replacing, mechanical support to repair industries.

Every vehicle has a different torque mechanism that needed to be followed because excess torque can damage the thread of nuts and bolts.

These are available in multiple types like a manual, and digital. These are most widely used by automobile industries to tighten lug wheels nuts.

#14. Alligator Wrench:

As the name suggests, Allen wrenches come with a shape that looks the same as an alligator’s open mouth. It has teeth on the inner upper jaw of the head whereas, the bottom jaw is plain.

Alligator wrench is used primarily to handle square head nuts and bolts. Earlier it was used widely used in agriculture, repair, automobile industries but now these have become obsolete as hexagonal shape nuts and bolts have replaced square-shaped nuts and bolts.

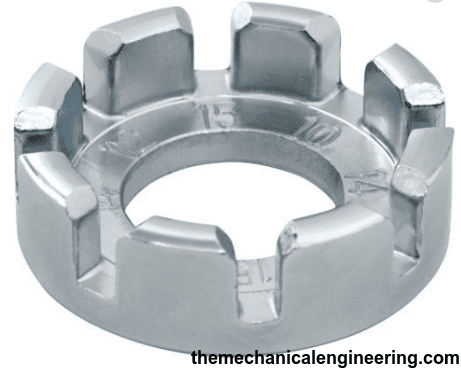

#15. Armorer’s Wrench:

Armorer wrench is a special type of wrench having a C-shaped opening at the open side and having teeth to grip the nuts or bolts easily.

Armorer wrenches are generally used for loosening or tightening nuts and bolts or guns, rifles, or armorers as the name suggests. It has a square or round hole in the handle to attach the ratchet handle.

Armorer wrenches come in various sizes and shapes according to the gun or the rifle.

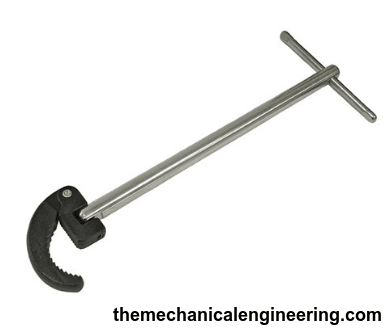

#16. Basin Wrench:

Basin Wrenches are the wrenches that are designed to perform a function in the difficult area under fixtures like sink, basin, or toilet.

It has a tooth on the jaw on the head these teeth help in achieving better grip. It has a transverse handle at the other end. This is also known as the faucet wrench because of its uses.

#17. Bionic Wrench:

The wrenches have the same design as the piler having a round head with the handle. These round head helps to grip the head of the nuts or bolts firmly. You can say it as an adjustable box-ended wrench.

#18. Bung Wrench:

Bung wrenches are specialty wrench specifically made for removing the caps from drums. It is a socket-style wrench that has teeth on the head that fits into the sockets of the cap.

It helps to reduce the pressure of the drum while removing the cap. These are also called drum plug wrenches. It is available in multiple types and even has a sparkless wrench which is specially made to open an inflammable drum cap or plug.

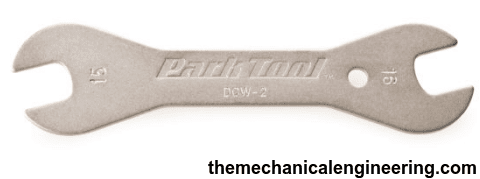

#19. Cone Wrench:

Cone wrench is the wrench specifically used at the places where the open-end wrench is very thick to reach. These wrenches have a thin and wide head.

These wrenches have less strength and a large head. These are mostly used for bicycles and for adjusting the leveling feet of the washing machine. Most cycle front hubs use 13mm whereas rear wrenches use 15mm wrenches.

#20. Die-Stock Holder Wrench:

Die-Stock Holder wrench is the basis of tap and dies sets. This is available for both male and female sets of dies.

This double-handed wrench help to hold the dies in the middle with the help of a screw to tighten them. These wrenches create a thread on the nuts and bolts. This is primarily used for threading operations.

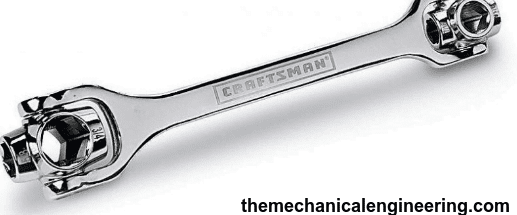

#21. Dog-Bone Wrench:

Dog-bone wrenches have a shape similar to the dog bone as the name suggests sometimes it is also called a dumb-bell wrench. This wrench comes with two box ends with multiple sizes of sockets.

It is primarily used for bicycle maintenance and repair, but its ability to set on multiple nuts and bolts makes it useful everywhere.

In British English, it is also known as dog bone spanner. For more flexible operation some dog wrenches come with swivel heads.

#22. Drum Key:

Drum key wrench is mainly used to tune the drum (music instrument) and other percussion instruments. This has a flat handle with a square-shaped socket that fits into the head of nuts and bolts.

Drum keys that have longer handles can apply more torque compared to keys with shorter handles. It has a T- shape.

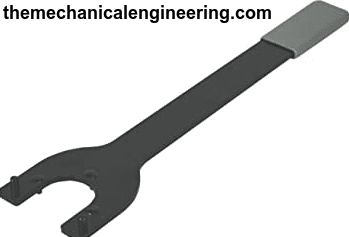

#23. Fan Clutch Wrench:

Fan clutch wrenches are specially meant to remove fan clutches on cars. These wrenches have a U-shaped head with the handle attached. These are available in different sizes in the kit.

Some of the wrenches also have a square opening at the other end. That helps to open the hex-shaped nuts and bolts. While another end works as a clutch holding tool.

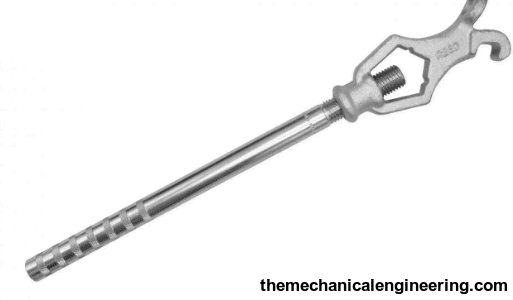

#24. Fire Hydrant Wrench:

Fire Hydrant wrench is specially made for the use of fire hydrants. It is a specific use wrench that cannot be used for other purposes. It comes with a pentagonal or five-side head and a long handle attached to it that provides the required amount of torque.

The handle is the adjustable handle helping to perform the required action easily. Without this wrench, it is difficult to open the nuts and bolts of the hydrant. These are used to open the cap of hydrants and open the valves of the hydrant.

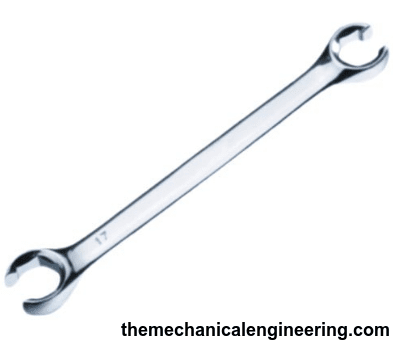

#25. Flare Nut Wrench:

A Flare nut wrench is specially used in plumbing for gripping the nuts at the end of the tubes. It is also similar to open-ended wrenches but the only difference is these have much wider openings compared to open-ended wrenches.

A Flare nut wrench is made to fit across the tubes but can also grip the nuts or bolts. The opening head consists of the tooth for better gripping of the nuts and bolts.

This provides better contact with the nuts and bolts in plumbing that are generally softer and can get damaged if worked with an open-ended wrench.

#26. Garbage Disposal Wrench:

Garbage disposal wrenches are used to carefully remove the trash and debris that clog the shredder plate.

It swivels head positions itself above the shedder plate into the disposal garbage for quick elimination of the disposal. it comes with an extended arm to keep your hands away from the garbage.

Garbage disposal wrenches are specifically used only for garbage disposal they don’t have any use elsewhere.

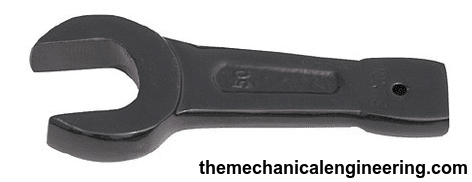

#27. Hammer Wrench:

Hammer wrenches are also known as striking wrenches. It has a box end or the open end at one end and another end of the handle has a block end.

The block at the end is used for hitting with the hammer to give an increased amount of force. It is usually thick and short in size.

This is generally used to tighten large size nuts and bolts by screwing them with a hand and then providing the required torque to tighten the nut by striking the wrench with a hammer.

Similarly, it is used to loosen the stubborn, struck, or rusted nuts and bolts by applying the required amount of force by striking it with a hammer.

Hammer wrenches are used in multiple industries and mechanical works, they are also used in plumbing and electrical works. In British English, it is also called slogging spanner or flogging spanner.

#28. Monkey Wrench:

A Monkey-wrench is the more classical form of adjustable wrenches and like alligator wrenches but it has a rounded handle and does not have any teeth on the jaws. An adjustable screw is fixed to the jaw to adjust the head according to the size of the nut or bolts.

#29. Pedal Wrench:

Pedal wrenches are the particular types of wrenches used only for bicycle or boat pedals they don’t have any other use. It usually has two or one U-shaped opening on the head and a handle.

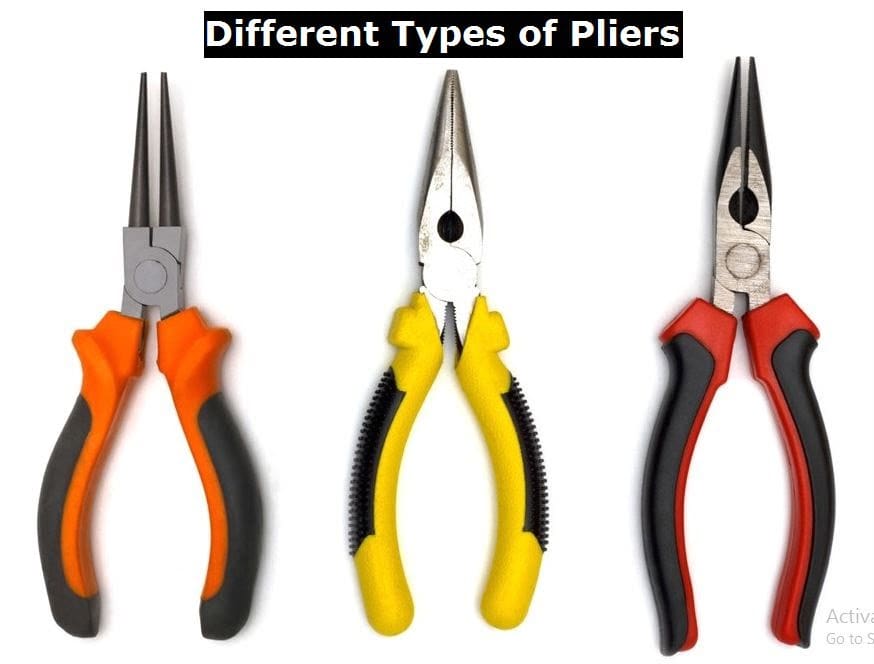

#30. Pliers Wrench:

Pilers wrenches are best suited for plumbing fitting and other materials that require a strong grip without teeth because teeth can cause damage to the pipes if we use wrenches with teeth it might leave its mark on the pipes.

It has a smooth jaw with the handle attached the set of jaws is connected with a bolt that can slide to adjust the opening of the jaws according to the size of nuts, bolts, or fittings. the name is derived from the way this tool is used it is similar to the piler.

#31. Plumbers Wrench:

Plumber wrenches are similar to pliers wrenches the only difference is the jaw is designed to give a strong grip to hexagonal nuts, bolts, and fittings. It is best suited to work on pipes and fittings in plumbing. The jaws can be adjusted according to the size of pipes and fittings.

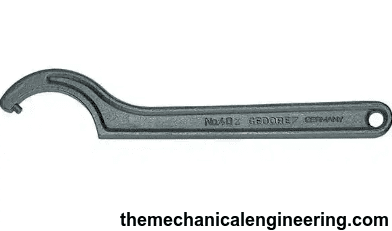

#32. Spanner Wrench:

It is suitable for loosening or tightening the nuts or bolts that have holes on the head as these have one or several pins/hooks that fit into the head of nuts/bolts. It has a C-shaped head with one or more pins or hooks.

#33. Spark Plug Wrench:

The Spark Plug wrench is specifically used for tightening and loosing the spark plugs. It is a T-shaped wrench with sockets on both ends. You can find these wrenches at any bike repair shop or with people who do engine servicing and maintenance work.

#34. Spoke Wrench:

A spoke wrench is used for maintaining the spokes of the bicycle. You may find them in every bicycle repair shop. These are very tiny in size and have slots on one end that easily fits around the spoke to loosen or tighten them.

The other end fits around the nipple nut because of its drive head. This wrench can be rotated completely without removing it due to its compact size.

#35. Spud Wrench:

A Spud wrench is an open-ended adjustable or standard wrench with the spike on its opposite end used to align holes of the pipes and bolts. Now it has become obsolete because of the plumber wrench but sometimes it can be found in particular toolboxes.

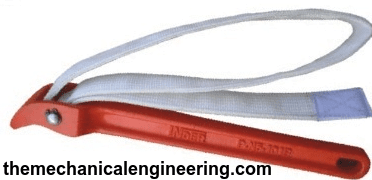

#36. Strap Wrench:

A strap wrench consists of a strap, leather, or a chain attached to the handle that tightens on its own. Used to grip smooth and cylindrical objects that are hard to grip with a standard wrench like an oil filter.

This is entirely dependent on friction between an object manipulated and a strap or chain and this is similar to the pipe wrench the only difference is that the pipe wrench has an adjustable head whereas the strap wrench has a chain or the strap.

It is mainly used for oily & greasy objects. Larger chain wrenches are also known as “bull tongs” are used for wider pipes that are used in borewells and deep wells.

#37. Stubby Wrench:

Stubby wrench is the shorter version of the combination wrenches which has one end open and another end has a loop allowing it to fit in compact places. Some newer models have a hinge in the handle that allows either end to be bent for better use.

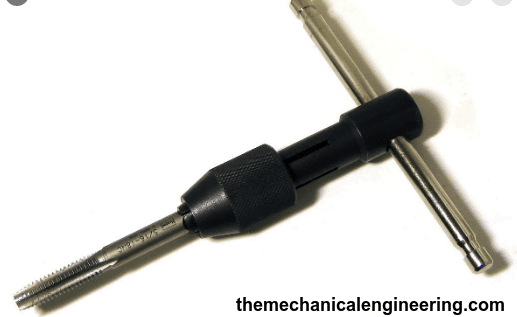

#38. Tap Wrench:

Tap wrenches are used for turning square drive-in taps. It is either T-shaped or has a double handle and a socket in the middle of the handle. This wrench is a specific wrench that can only be used for taps. You might get this wrench with any plumber.

#39. Tension Wrench:

These are the wrenches you might have seen with people who are doing lock picking means opening a lock without the key by manipulating the components of the lock.

You might have also seen in pictures or web series people opening the lock without keys. These wrenches are used to apply tension while picking the locks. These are also called torque wrenches.

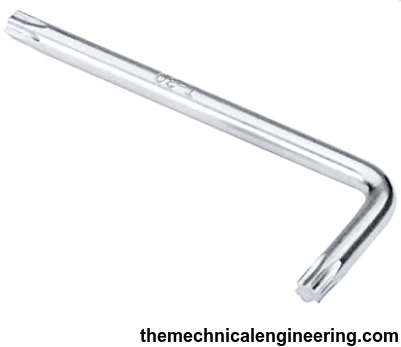

#40. Torx Key:

Torx key wrenches are similar to hex keys. The only difference is these fit in the star-shaped nuts whereas hex keys fit in hexagonal-shaped heads. These can be also seen in the swiss army knife and wrench kit.

#41. Dental Key:

The dental key is specially used by dentists to pull the teeth.

#42. Chunk Key:

This is used to loosen or tighten the chunk. In other words, it can be defined as A chunk is a type of fastener used to hold circular objects.

Internal Resources:

- 14 different types of Screwdriver

- Types of Wrenches

- Pliers Types

- Difference between Nuts and Bolts

- Planer Machine

- Slotter Machine

- Grinding Machine

- Lathe Machine

- Drilling Machine

- Shaper Machine

Reference [External Links]:

Conclusion

Wrenches are an important mechanical tool and are used in multiple industries like automobile, aviation, production, repair & maintenance industry. Without the wrenches, it’s nearly impossible to imagine the way we would be loosening or tightening the nuts and bolts.

We have seen multiple classifications and types of wrenches like a standard wrench, combination wrench, torque wrench, etc. These all wrenches are used in multiple types of works and industries. There are also multiple types of keys like torque key, the dental key used to open nuts, and bolts of difficult places.

Hope So this article has helped you to understand different types of wrenches in the deeper sense. Comment down all the queries related to the topic.

Discussion about this post