Hammer is a hand tool device that is used for striking the workpiece for several purposes. In this article, we will look at 32 Different Types of Hammer and their uses in detail.

Hammers are used in the forging industry to shape the work price and this is also used in household work.

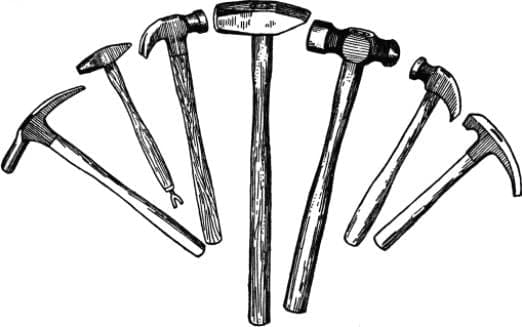

Different Types Hammer:

There are thirty-two different types of Hammer and those are:

- Ball Peen Hammer

- Claw Hammer

- Club Hammer

- Dead Blow Hammer

- Framing Hammer

- Rubber Mallet

- Sledge Hammer

- Tack Hammer

- Blacksmiths Hammer

- Blocking Hammer

- Brass Hammer

- Brick Hammer

- Bushing hammer

- Cross Peen Hammer

- Chasing Hammer

- Drywall Hammer

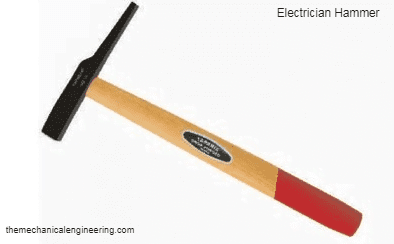

- Electrician Hammer

- Hatchet Hammer

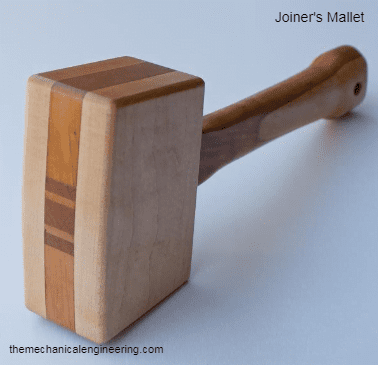

- Joiner’s Mallet

- Lineman’s Hammer

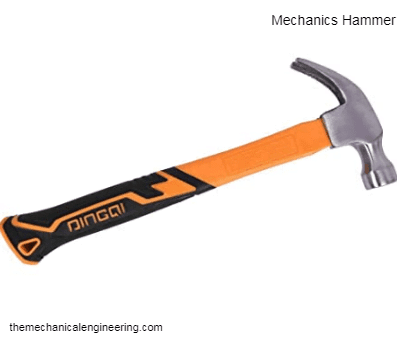

- Mechanics Hammer

- Nail Gun

- Piton Hammer

- Planishing Hammer

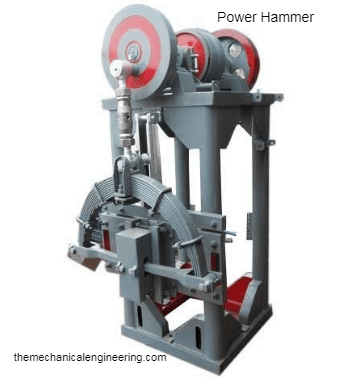

- Power Hammer

- Rip Hammer

- Rock Hammer

- Scaling Hammer

- Scutch Hammer

- Shingle Hammer

- Straight Peen Hammer

- Welding Hammer

Now we will study one by one in detail.

1. Ball Peen Hammer:

The ball-peen hammer is also known as a mechanist hammer. It has two heads one is flat and another is pein. The metalworking process specifically uses this hammer. It has a rounded pein. Its primary work is shaping metal, closing rivets, and rounding the edges of pins and fasteners.

Handles are primarily made of wood. Peeing process in older days uses this hammer as a primary tool. Blacksmith uses this hammer primarily for delivering the blows for forging or for hitting other forging tools. For matting, the edges of the gasket use this hammer.

2. Claw Hammer:

Claw hammers are the most commonly used hammers. It has one side flat rounded and another side curved having, a fork or V-like structure for pulling the nails. This hammer is used for pushing the pin or removing the nail.

It is primarily used for woodworking. Carpenters use this hammer majorly but, now it can be found on any workshop, home, or construction site. This is not suitable for metalworking processes or hard hammering on metal surfaces.

The handle of this hammer is made up of wood, metal, or glass fiber that comes with or without a rubber cover.

3. Club Hammer:

Club hammers are a usually smaller variant of a sledgehammer. These have doubled sided flat heads that are similar to a sledgehammer. It is relatively smaller and lighter than a sledgehammer making it easy to use with a single hand.

A club hammer is generally not compatible with commercial works. It is best suited for light demolition work, masonry work, driving nails in masonry work, and with the steel chisel.

This hammer is useful as an impact tool for cutting stones and metal because its head drives the chisel more deeply into the metal being cut. This is also known as drilling or lump hammer.

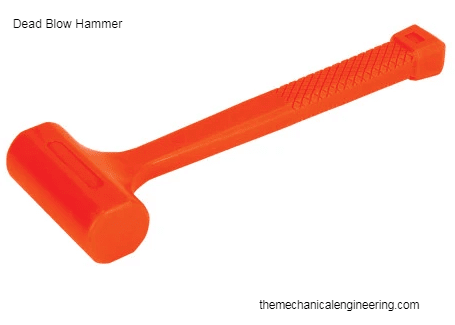

4. Dead Blow Hammer:

A dead blow hammer is a specialized hammer used to minimize the harm caused on the hitting surface or in managing striking force with minimizing rebound. The minimal rebound helps avoid accidental damage, specifically at the compact areas and on uses such as maintenance of hydraulic cylinder.

It is best suited for works that require soft hits. The head of the hammer can be hollow or solid which helps in distributing the energy of the hitting for a longer period and reduces rebound.

It is either a solid rubber or plastic head or hollow head filled with sand or lead shot. It can be used in woodworking for tapping wood together or apart without harming the surface or in an automobile shop for dislodging the parts and repairing dents.

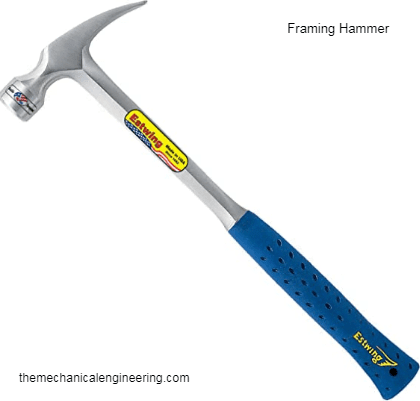

5. Framing Hammer:

The framing hammer is similar to the claw hammer but the major difference is framing hammer is much heavier than the claw hammer approx two times the weight of the claw hammer.

This is designed to hit with harder force on a larger nail. As the name suggests the primary function of the hammer is to assemble frames on the house. Its heavy head with longer handles helps in driving the nails easily in the wood.

The claw head is used in extracting the nails. The handle is made of wood for better grip.

6. Rubber Mallet:

A rubber hammer is an extremely helpful tool for work that requires soft blows. As the name suggests the head of the hammer is made up of rubber with a wooden handle. This hammer is commonly used in woodworking, upholstery, & sheet metal, which requires softer but firm blows. This hammer is perfect to force the plasterboard in place without harming or damaging it.

7. Sledge Hammer:

A sledgehammer is similar to a club hammer the major difference is it has a longer handle and heavier head. It has a large flat metal head designed for heavy and large blows. The large handle and heavy head help to gather force during a swing and apply a higher amount of force as compared to a normal nail hammer.

Another difference between a normal nail hammer and a sledgehammer is, It can distribute force over a large area whereas a normal hammer concentrates force to a particular area. It is used for masonry work, driving stakes, and breaking concrete. This is the best tool for demolition purposes.

8. Tack Hammer:

A tack hammer is also known as an upholstery hammer is a lightweight hammer used for the installation of upholstery fabric on the furniture using tacks or small nails.

One side of the hammer is a small flathead and another side is magnetized to help in the positioning of tack or a small nail remover like a claw hammer.

These hammers are usually small and perfect for securing upholstery. Now staple gun has widely replaced upholstery hammers.

9. Blacksmiths Hammer:

A blacksmith hammer is a type of sledgehammer where another head is slightly tapered and rounded. It is made for multipurpose forging to bend and chip the hot materials to provide shape according to the specific product.

It is used for shaping metal on a block or anvil. This is specifically designed for a particular task and cannot use for a common task.

10. Blocking Hammer:

This is another type of hammer used by the blacksmith; it has a common wooden handle with a double-sided head where one side is square-shaped and another is a cylindrical head. This is primarily used for shaping the metal on an anvil or the block.

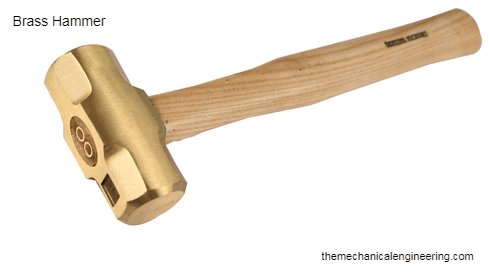

11. Brass Hammer:

The brass hammer has a thin cylindrical brass head which is perfect for hitting the steel pins into various materials without damaging the surface.

It is useful in various areas but you can most commonly find them in an automotive shop and woodworking industry. These hammers have less reverberation than steel hammers to prevent unwanted movement.

12. Brick Hammer:

A brick hammer has one side like a chisel used for rounding the stones and a blunt side is used for splitting the bricks, stones, and other masonry works.

This hammer can be used as both a traditional common hammer and a chisel tool.

It is also known by the names like a stonemason’s hammer, bricklaying hammer, and a tile settler’s hammer. This is best suitable for demolition work, bricklaying, and general masonry work.

13. Bushing hammer:

A brush hammer is a masonry tool used to provide texture to the stones and concrete. This exists in many forms from manual to machine powered but, the basic functional property is similar. This consists of small cones or pyramids on the hammerhead that leaves an imprint on the stones or the concrete.

This is used to create a rough texture to the stone to improve its appearance or to make it less slippery. These are also used to increase the bonding effect when new concrete is applied over the concrete surface.

14. Cross Peen Hammer:

A Cross peen hammer consists of a regular hammerhead with a wedge-like pein on another side. This hammer is useful for those who hit their hand while trying to position a nail or tuck into the wood or plasterboard. The wedge side allows you to tack the nail without harming your fingers.

This hammer is generally used where space is compact usually in the corners. These hammers are used in woodworking, automotive & blacksmithing.

This is also used in metalworking. The handles of these hammers are made of hickory or ash as these woods absorb shocks & vibration while hammering.

15. Chasing Hammer:

The chasing hammer is very different from the common hammer it has one flat impact head and another side with a rounded peen.

The ball side is used for peening or smoothing out the dent, while the smooth side is used for chasing or indenting the metal. These are the specific types of hammers used for jewelry making.

You can easily find this hammer with any jewelry maker.

16. Drywall Hammer:

Drywall hammer is also known as drywall hatchet hammer. Its unique feature is its lightweight compared to other hammers.

So it becomes easy to carry. It is primarily used in the installation and removal of the drywall, which finishing material for interior walls.

The design of the hammer is a combination of a hammer and an ax. One side of the head has an ax blade with a notch at the bottom used to grip the nail and the other side has a traditional hammerhead.

The traditional hammerhead is used to prevent unnecessary knocks and dents of the drywall surface. And the edge is used to cut off excess margins of drywall carefully.

17. Electrician Hammer:

The electrician hammer is another variation of the claw hammer. This hammer is heavier than the normal hammer used to drive wire staples in tight locations.

One side of the head is similar to a claw whereas another side had an extended head for impact force.

The handle is made up of hard fiberglass that can withstand multiple impacts and absorb shocks. The handle has a rubber cover to make the handle electrically insulated to avoid electric shock.

18. Hatchet Hammer:

A Hatchet hammer is a combination of ax and hammer. One side is a flat head and another side is a shaped edge used for cutting. Users can switch over different tools by reversing the grip. In the olden days, it was used as a weapon.

In the modern day, it is used in various industries like construction, carpentry, and even mountaineering. This hammer is used in various emergencies.

The ability to cut like an ax has saved many lives over the year. This is an extremely useful tool in mountaineering as this is used to fix pitons & tents in ice rock or hard soil.

19. Joiner’s Mallet:

Joiner’s mallet is a traditional wooden hammer made of the solid wood block instead of metal. This hammer is an extremely helpful tool in project assembly shops, chiseling, inserting a dowel, and general purposes pounding operations.

It is less damaging to the wood or metal than a traditional metal hammer, particularly if the mallet head is covered with leather. A traditional wooden mallet’s relatively wide head spreads the impact over the wider area, minimizing the risk of dents and dings.

The larger face also helps in hitting the chisel easily. But as it has a wider head there are chances of smashing the finger so this hammer must be handled carefully.

20. Lineman’s Hammer:

Lineman’s Hammer is heavy and used to drive larger bolts and screws in materials such as electric poles. It is designed to swing much slower than traditional ball-peen or claw hammer allowing the hammerhead weight to do the job.

It may have a very simple design & structure but the concept is the same, with the two rounded solid hammerheads and a shock-absorbing handle with a rubber grip. This hammer is not useful for precise repetitive works. Most commonly used to work on telephone poles.

21. Mechanics Hammer:

Mechanic hammer as the name suggests used by mechanics to remove the dent from cars and panels. With the metal flat impact side and pointed impact tool, the style of the hammer is very different from the conventional hammer.

You can find this hammer easily with the mechanics and sometimes carpenters. This hammer helps in the different types of works in an automotive repair shop from removing any part to removing dents.

22. Nail Gun:

A nail gun is not technically a hammer but it performs a similar function as any normal hammer or claw hammer. It is used to drive or remove the nails from the wood or any different type of material. Now nail gun has widely replaced a hammer in many areas of work.

This is commonly driven by compressed gases, electromagnetism, highly flammable gases such as butane or propane, or in case powdered actuated instrument, a small explosive.

There are various versions available in the market like cordless, battery-operated, etc. Nail guns are common in construction sites, carpenter shops, DIY projects where multiple nails are driven in the least time.

23. Piton Hammer:

Piton hammer is also known as rock climbing hammer, In climbing a piton is a metal spike that is usually forced into the cracks and crevices of rock while climbing it. And this acts as an anchor to prevent the climber from falling.

Depending on the type of rock climbing intended, the head can be an anvil and heavy and lighter with a hollow handle. Lighter hammers are used when driving fewer pitons for minimizing weight loads, while heavy hammers are used when driving more pitons quickly with less fatigue.

These hammers come with interchangeable heads for allowing a wider variety of climbing techniques. These hammers are helping climbers for years and are one of the most important gears of climbing.

24. Planishing Hammer:

Planishing hammer is a classical metalworking tool. Planishing means to flatten, smooth, or polish the metal by hammering or rolling. The method of planishing uses many light blows to smoothen the metal formed by any other process.

The pein is tipped with a cylindrical die, and the head of these hammers is slightly convex. It is possible to exert a considerable force while causing minimum damage to the metal due to the shape of hammerheads.

25. Power Hammer:

A power hammer is a metal forging hammer that uses compressed air to move the piston up and down to hammer and shape the material. This is the fixed/stationary hammer it’s difficult to move this hammer from one place to another.

It works similarly to the hydraulic press the only difference is it can quickly shift the piston up and down hundreds of times per minute. These are used by blacksmiths, metalworkers, manufacturers, and in multiple industries.

It is perfect for shaping materials like steel and other metals that are less malleable with the traditional manual power hammer.

26. Rip Hammer:

Rip hammer is also known as the professional version of the claw hammer. The major difference between a traditional claw hammer and a rip hammer is the rip hammer has a straight claw and is usually heavier than the claw hammers.

This is the most durable hammer, which is widely used in demolition and building work for tasks such as digging holes and breaking down wood and brickwork.

27. Rock Hammer:

A rock hammer is also known as a geologist hammer, pick hammer, or geological pick. In geology and evacuation, the rock hammer is most commonly used. It has a square head on one side and another side is like a chisel or the pick.

It helps you to use the flathead to smash smaller rocks as well as chisel out stones and bricks. They’re used in geology to get a fresh surface of the rock to figure out its structure, bedding orientation, nature, mineralogy, history, and field strength estimate.

The chisel is used in removing the vegetation, forming small holes, and in soft rock splitting. Sometimes bricklayer’s also use a rock hammer to break to loosen the part of brick joints.

The hammer also helps geologists to assess the granularity, soundness, and resistance to the fracturing of the rock, all of which are essential determinants to consider.

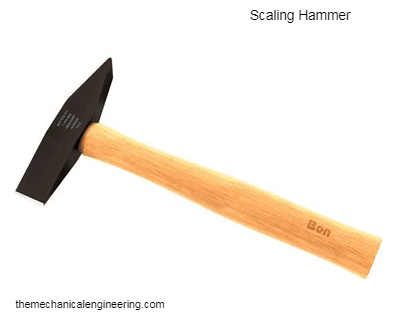

28. Scaling Hammer:

A scaling hammer is a completely different-looking tool consisting of the combination of a pick and a chisel. This type of hammer is extremely useful in not only removing the rust and scale but also extremely hard coating that can accumulate within boiler over the time.

Its extremely thin points help you to get in the surface of rust and coating and remove it.

This hammer is also known as a boiler scaling hammer because of its use. These are available in multiple designs in the market.

29. Scutch Hammer:

Scutching is the process used to remove the layer of old mortar from the brick. The hammer comes with one side or both side chisel-like design that has a slot to attach different types of scutches.

These hammers are useful for cleaning the bricks removing the old mortar, cutting the rocks, trimming the stones.

This helps in avoiding the inconvenience of holding the chisel and hammering. This makes scutching work so easy to perform.

These are also used for removing the floor tiles and sculpting or removing plaster from the wall. In these hammers, we can also replace the scutch combs.

30. Shingle Hammer:

Shingle hammer is also known as roofing hammer.

These hammers have one side square head and another side spike head that usually has a small claw at the end of the spike for pulling out nails. Spikes are used to prevent the shingles and slates from shattering and breaking.

31. Straight Peen Hammer:

A straight peen hammer is much like to cross peen hammer used for shaping the metals and fixing the nails in position.

The major difference between a cross peen hammer and a straight peen hammer is that the peen of a straight peen hammer is vertically aligned.

It is generally used in metalworking industries but you can also find this hammer with carpenters or mechanics. The handle of this hammer is longer.

32. Welding Hammer:

A welding hammer is used for dressing the welds after they cool down. This hammer is equipped with a chisel-like pointed edge that helps to remove the slag from the welding rod.

It also consists of a wire brush that is at the end of the hammer used to clean, and remove any remaining residue from the weld. The welding hammer is not used with the wire welders that use wire and gas instead of the flux-covered rods.

Internal Resources:

- Types of Hammer

- Types of Wrenches

- Screwdriver Types Explained in detail

- Pliers Types

- Difference between Nuts and Bolts

- Forming Process

- Forging Tools

- Planer Machine

- Slotter Machine

- Grinding Machine

- Lathe Machine

- Drilling Machine

- Shaper Machine

Refernce [External Links]:

- https://en.wikipedia.org/wiki/Hammer

- https://www.youtube.com/watch?v=FG0CpO5S1qI

- https://www.youtube.com/watch?v=uCplzSbsqtI

Conclusion:

Hammers are an important mechanical tool and are used in multiple industries like automobile, aviation, production, repair, and maintenance industry. Without the hammers, it’s nearly impossible to imagine the way we would be driving or removing the nails.

We have seen multiple types of hammers like a standard hammer, ball pein hammer, dead blow hammer, etc. These hammers are used in multiple types of works and industries.

There are also multiple types of specialized hammers like an electrical hammer, blacksmith hammer, etc. which are used for specialized works.

Hope so this article helped you understand all the hammers in detail. Please mention all your related queries.

Discussion about this post