Hi, In this article we will study the difference between UP and DOWN Milling Machine. And also you can download whole articles in PDF format at the end.

Before moving to our main topic lets have small overview on UP and DOWN Milling.

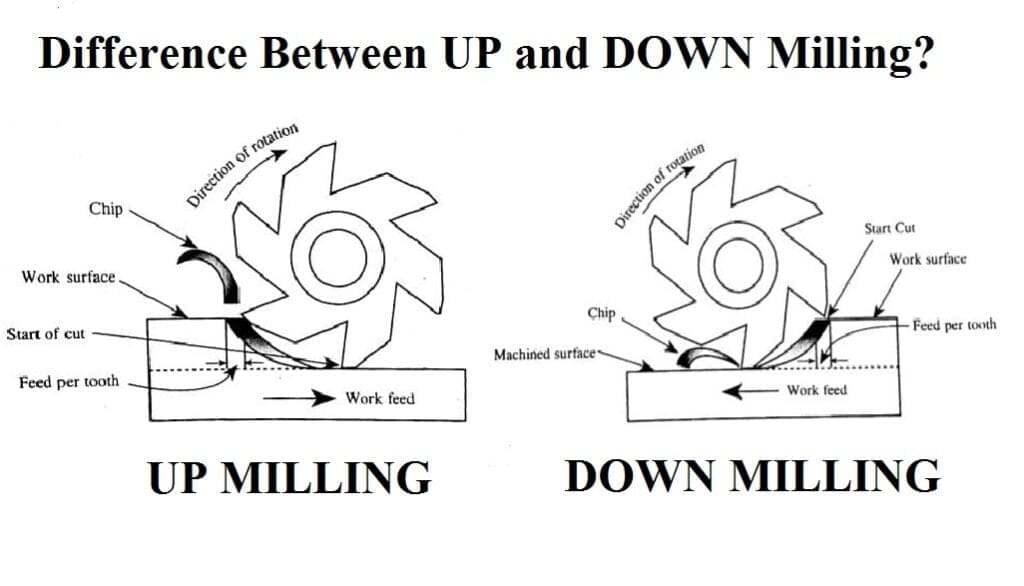

What is UP Milling?

- In UP Milling to perform the operation the cutter and feed moves opposite to each other.

- It is also called a Climb UP or Conventional Milling.

What is Down Milling?

- In Down Milling to perform the operation the cutter and feed move in the same direction with each other.

- It is also called a Climb Down Milling.

Difference Between UP and DOWN Milling Machine:

| UP MILLING MACHINE | DOWN MILLING MACHINE |

| UP Milling is known as the Conventional Milling process. | Whereas, Down Milling is known as the Climb Milling process. |

| The cutting forces act upward in the UP Milling as you can see in the diagram. | Here the cutting forces act opposite to the up milling or you can say downward. |

| The UP Milling process is used for rough purposes. Whereas, | Down Milling or Climb Milling Process is used for the final or finishing operation. |

| Therefore, Surface finishing is not good. | Here surface finishing is great. |

| It is used for cutting of brass, bronze, and ferrous materials. | But This one is applicable to aluminum and aluminum alloys. |

| The tool wear rate is more here because the direction of the rotary cutter is against the feed. | The tool wear rate is less here because the cutter is in the same direction as that of the feed. |

| The tool life is not much because of toll wear rate is high. | Here tool life is more because there is less tool wear rate compared to UP Milling. |

| UP Milling is a traditional type of process. | Down Milling is used nowadays for better surface finish. |

| Here in UP Milling, The cutter rotates against the direction of the feed. | But In Down milling, the cutter rotates in the same direction of feed. |

| Why did we call this process is UP Milling Process? Because The material from the surface or cutting chips is thrown in the upward direction. | Here The cutting chips are removed in a downward direction, So it is called Down Milling. |

| UP Milling takes a large amount of force compared to climb down milling. | But it do not takes much amount of forces. |

| UP Milling is less for chip management. | Down milling is more suitable for chip management. |

| If the workpiece material is brittle then the UP Milling process is followed. | Down Milling can not perform operation when work piece material is brittle. But if it perform then chances of wear and tear of tool. |

| In UP Milling the backlash eliminator is not required. | But here Backlash eliminator is required, especially when the machine is older. |

Related Article

Milling Machine

Lathe Machine

So Here we studied the difference between Up Milling and Down Milling Machine. If you like the article Please do not forget to share it on social media. Till then Thank you. We will meet in other articles.

Discussion about this post