Hello reader! Hope you are great. In this article, we are going to study the Definition, Parts, Working, Types, Materials, Advantages, Disadvantages, and Applications of Crankshaft in very detail.

Talking about the history of Crankshaft: The earliest hand-operated crankshafts were evident in China in 200 BC. These were used for architectural works. However, the conventional crankshafts do not seem to be originating from China.

The use of the crank was evident in the 2nd century AD in the Roman empire. The crank connected with the connecting rod has also been found in the Roman empire in the 3rd century AD. After the 16th century crank with connecting rod and pins were evident in Europe.

These were used in various machines of that time. With time, several changes were made and crankshafts were being used in automobiles.

Note: The PDF you can get it at the end of the article.

What is a Crankshaft?

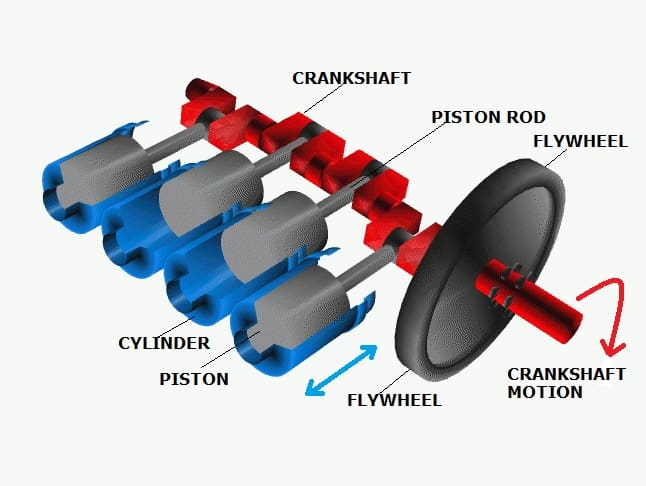

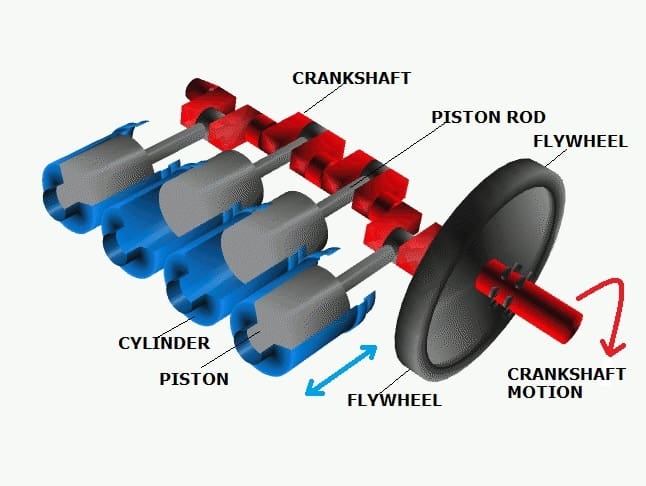

A crankshaft is a component in the transmission system which changes the reciprocating motion of the piston into rotational motion. This helps in achieving the rotational Power output from the reciprocating input given by the piston.

The crankshaft is an extremely important component in any automobile which needs to be designed with maximum accuracy and precision.

If there is a mistake with the design of the crankshaft the chances of engine failure may increase considerably.

One end of the crankshaft is connected to the engine and another end is connected to the flywheel.

Construction of Crankshaft:

The main journal bearings form the axis of the crankshaft shaft. One end is connected with the flywheel flange and another end is connected with a pulley shaft.

Two counterweights are attached with the help of a rod-bearing journal to form a pair of counterweights. Each pair is attached with the main bearing journal to form a sequence of counterweights. The rod bearing journals are also connected to the piston connecting rod.

Different components involved in a crankshaft are given below:

#1. Flywheel flange:

As the name suggests the flywheel of the vehicle is attached to the crankshaft with the help of a flywheel flange. Flywheel flange is attached to one end of the crankshaft.

It is designed in such a way that it can hold the flywheel rigidly. This is because the flywheel is a heavy mechanical device that rotates at very high rpm.

#2. Pulley end:

The pulley end of the crankshaft is connected to the engine and it can also be connected to the gearbox.

#3. Counterweight:

The counterweight is the most important element of a crankshaft. These help in the smooth running of the crankshaft. When the piston reaches the top dead center the heavier side of the counterweight reaches its lowest point.

And when the piston reaches the bottom dead center the heavier side reaches its highest point. This results in smooth running due to the change of potential energy created by the counterweights.

#4. Balance weight:

The balance weights are some additional weights that are located in the counterweights to provide improved stability.

#5. Main bearing journals:

The main bearing journal has its axis coinciding with the axis of the pulley end and the flywheel flange. These act as the connecting elements between the counterweights. The main bearing journal also forms the axis of rotation for the crankshaft.

#6. Rod bearing journals:

The rod-bearing journals are used to connect the piston with the crankshaft. The pistons are attached to the rod-bearing journals with the help of pins.

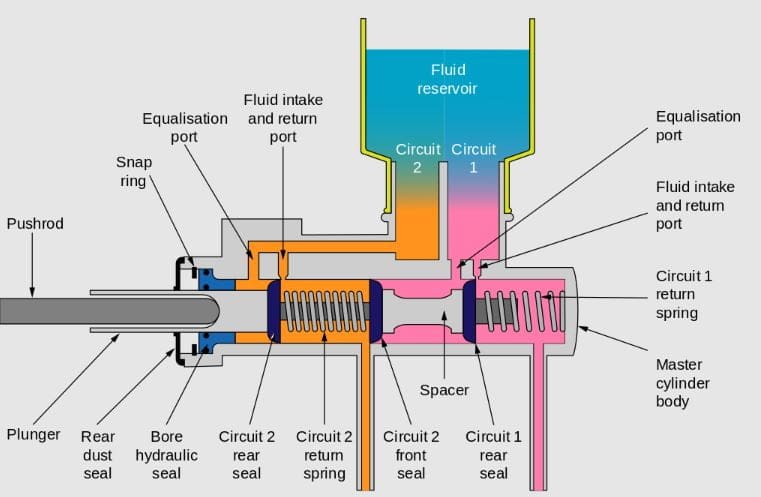

#7. Oil passage:

Oil passage is the passage that connects the main journal bearing to the rod journal bearing. The oil from the main journal bearing flows towards the rod journal bearing for lubrication purposes.

Working of the crankshaft:

Here are the following steps:

- When the engine starts the flywheel provides a motion to the crankshaft.

- The crankshaft pushes the piston towards the top dead center for a power stroke.

- At this time the counterweight is at the lowest point.

- When the piston undergoes the power stroke and reaches the bottom dead center the heavier side of the counterweight reaches its topmost point.

- After the power stroke, the piston energy is lost. And the piston cannot reach the top dead center again on its own.

- The energy required by the piston to reach the top dead center again after the power stroke is provided by the falling counterweights.

- On the other hand, the crankshaft also converts the reciprocating motion of the piston into the rotational motion required by the gearbox.

Types of crankshaft:

There are various types of crankshafts used for different purposes. Some of the important types of crankshafts are given below:

#1. Single piece crankshafts:

A single-piece crankshaft is made of a single solid section of a certain material. These crankshafts are specifically designed to be used in multi-cylinder engines. They are suitable for working at moderate and high speeds as well.

It can withstand heavy loads and vibrations generated due to various stresses developed in an engine. These types of crankshafts undergo more stress due to their rigid structure. The image of the single-piece crankshaft is given below.

#2. Built-up crankshaft:

In a Built-up crankshaft, all the parts of the crankshaft are manufactured separately. These parts or components may or may not be of the same materials. Every part including pins is manufactured separately. These are made to be fitted together using the shrink fit technique.

As we know, metals tend to expand when the temperature is increased and they tend to contract when the temperature is decreased.

This principle is used to fit parts together as the size of the parts increases when the temperature rises and decreases when the temperature falls to form a tight fit. The big end of the built-up crankshafts is made by one single solid piece of the respective material.

The image of Built-up crankshafts is given below.

#3. Semi built crankshaft:

In semi-built crankshafts not all parts are manufactured separately and assembled, instead, some of the parts are manufactured and assembled separately. These separately assembled parts are counted as one unit or part. Then this part or unit is assembled with the other parts of the crankshafts. This type of crankshaft is used in diesel engines on ships.

#4. Forged crankshafts:

Forging is a process of heating the metal object and then giving it the desired shape with the help of various forces. A Forged crankshaft is made by forging a single block of metal into the desired shape. This eliminates the need for welding or heat shrinking for fitting the different parts.

Forged crankshafts are compatible with moderate-speed engines such as generators. These are not a suitable option for heavy two-stroke engines. Sometimes the Forged crankshafts need to undergo hardening processes for rigidity.

#5. Welded crankshafts:

As it is evident from the name itself that the crankshaft in which the parts are manufactured differently and are welded together is called a welded crankshaft. The strength of welded crankshafts is very high. This also increases the cost of production of welded crankshafts. Due to high cost, these crankshafts have limited applications and cannot be used everywhere.

#6. Cast crankshafts:

The cast-iron crankshafts are manufactured by the casting process. A cast-iron crankshaft is generally used in petrol and diesel engines as they are cheap to manufacture.

It is also subjected to heat treatment to increase the tensile strength and hardness. This increases the lifespan of the crankshaft. The manufacturing process of cast crankshaft is quite simple.

#7. Billet crankshaft:

Billet crankshafts are made of steel which consists of aluminum, chromium, molybdenum, and nickel. These crankshafts are easy to machine and the design is also uniform. The billet crankshafts may be said to be the best type of crankshaft.

Functions of Crankshaft:

A crankshaft serves a very essential part in the working of an engine and has endless functions which are described below.

- Conversion of linear motion of an engine to rotating motion is done by the crankshaft.

- Crankshafts regulate the amount of oil required for lubrication in an engine.

- It deliver power to the piston whenever it is needed. This power delivery takes place due to the falling of the counterweights. Hence we can say that a crankshaft ensures the smooth running of an internal combustion engine

Materials used for making crankshaft:

Crankshafts are generally made up of steel due to their high strength and hardness. The fatigue strength of steel is also very high when compared to other materials of the same cost.

Some of the materials used for making crankshafts are.

#1. Manganese-molybdenum steel:

Crankshafts manufactured using manganese-molybdenum steels are done using the forging process. The crankshafts are cheap and are used for moderate-duty petrol engines. It consists of 1.5% manganese, 0.3% molybdenum, 0.38% carbon, and 97.82% iron. The Brinell hardness number of manganese-molybdenum steel is around 250 BHN.

#2. Chromium-molybdenum Steel:

This type of steel is used for medium and heavy-duty petrol and diesel prices. It consists of 1.2%chromium, 0.4% molybdenum, 0.3% carbon and the rest is iron. Brinell hardness number for Chromium-molybdenum Steel is about 280 BHN.

#3. Nickel-chromium-molybdenum Steel:

The fatigue strength of these steels is very high and is used in diesel engines. It consists of 2.5% of nickel, 0.31% carbon, 0.65% chromium, 0.5% molybdenum and the remaining is iron. The Brinell hardness number for this steel is 300 BHN.

#4. Nodular cast iron:

Nodular cast iron is a grey cast iron that has graphite nodules in perlite medium. These are also known as ductile cast iron due to their high ductility. The carbon content and silicon content are around 3-4% and 1.8-2.8% respectively. The Brinell hardness number of nodular cast iron is around 200-300BHN.

Advantages of crankshaft:

The following four points illustrate its advantages:

- Greater efficiency.

- Provides smooth running of an engine.

- Provides better torque.

- Increases engine power.

Disadvantages of crankshaft:

The following three points illustrate its disadvantages:

- Failure of bearings may occur.

- The total cost of manufacturing is high.

- Friction is increased which results in the heating of the crankshaft.

Types of failure in crankshaft:

There are very less chances that the crankshaft gets fail or not work. In most cases, this is working fine. But there are some common failures of the crankshaft and those are Worn journals and Fatigue.

- Worn Journals: The worn journal failure occurs when an insufficient amount of oil pressure is available. The journal makes contact with the bearing surfaces and gradually the clearance between them increases and worsens the oil pressure. If we can not keep taking care of it then it may cause serious problems for an engine. Worn journal failure destroys bearing and causes heavy damage to the engine.

- Fatigue: The fatigue failure occurs on the fillet where the journal and web are joined.

- When the shaft material is not as effective as it should be then there may be failure occurs.

- Using of Wrong bearing shell.

- Not checking and changing with time, components like engine oil, oil cooler and filter can damage the crankshaft.

- Because of earlier bearing failure and annealed bearing journals, the crankshaft material gets failed. Or

- The bearing journal has become soft as a result of premature bearing failure.

Internal Resources:

- Lubrication System Types

- Braking System Types

- Magneto Ignition System

- Battery Ignition System

- Single Plate Clutch

- Multi-Plate Clutch

- Flywheel

- Camshaft

- Propeller Shaft

- Clutch complete Notes

- Electronic Ignition System

Reference [External Links]:

Conclusion:

So here we have studied Crankshaft in detail. Let me know what else I can help you in this topic or any other topic?.

Discussion about this post