Hello reader, Today we are going to discuss types of fit in detail. It is a sub-topic of metrology and measurement where I have discussed various topics in detail.

Notes: At the end of the article you can get a PDF version and you can download it.

So let’s start with the Introduction of Fit,

To serve a common purpose in manufacturing it is important to merge or combine various operations with each other. Whenever we produce a part of any system, it requires various other factors like how to use it, where to use it, and what will be its dimension, and so on. According to that, we develop our product.

In the same way, we see types of fits and their relations with components.

What is Fit?

Fits are assembly conditions between Hole and Shaft. With fits, we understand how tight and loose the two components are connected. So it is a mating relationship between two components.

When a part and various other components are looking to be designed then engineering fits are taken as geometrical dimensions where it is the clearance between two mating parts in which it depends on the requirement of the size of clearance.

In engineering, fits have stated the term as a “shaft and hollow”. so it is the degree of freedom of tightness between two mating parts.

Whenever we assemble parts of a machine, we have to be fit between two parts then only he or she can assemble.

Considering two fits such as Running feet and Sliding feet: Suppose we have a hole and a shaft. What happens in the running fit is that the shaft can easily rotate inside the hole. In the same sliding feet, the shaft is slide in the hole, so we design it accordingly.

Minimum and Maximum Limit of Hole and Shaft:

The following points to understand Minimum and Maximum Limit of Hole and Shaft:

- In hole and shaft, we have a minimum limit and maximum limit.

- The minimum limit means the minimum size of the shaft or diameter of the shaft. Similarly, the maximum limit means the maximum diameter of the shaft which is permitted or we can say the maximum size of the shaft.

- The dimension of the hole and shaft can vary from a minimum limit to a maximum limit.

- In the case of a hole when we are removing material from the hole that is increasing the size of a hole is called the maximum limit so the maximum limit is corresponding to the maximum material removal from the hole.

- Whereas when we talk about the minimum limit for the hole it indicates the maximum material which is present.

- So hole and shaft there exactly opposite to one another

- In the case of the shaft where the material is minimum, the size of the shaft is minimum Whereas in the case of a hole where the material is maximum present then it is called a minimum limit and when the material is removed then we get the maximum limit for a hole.

Now we will understand types of fit in detail. So let’s start:

Types of Fit:

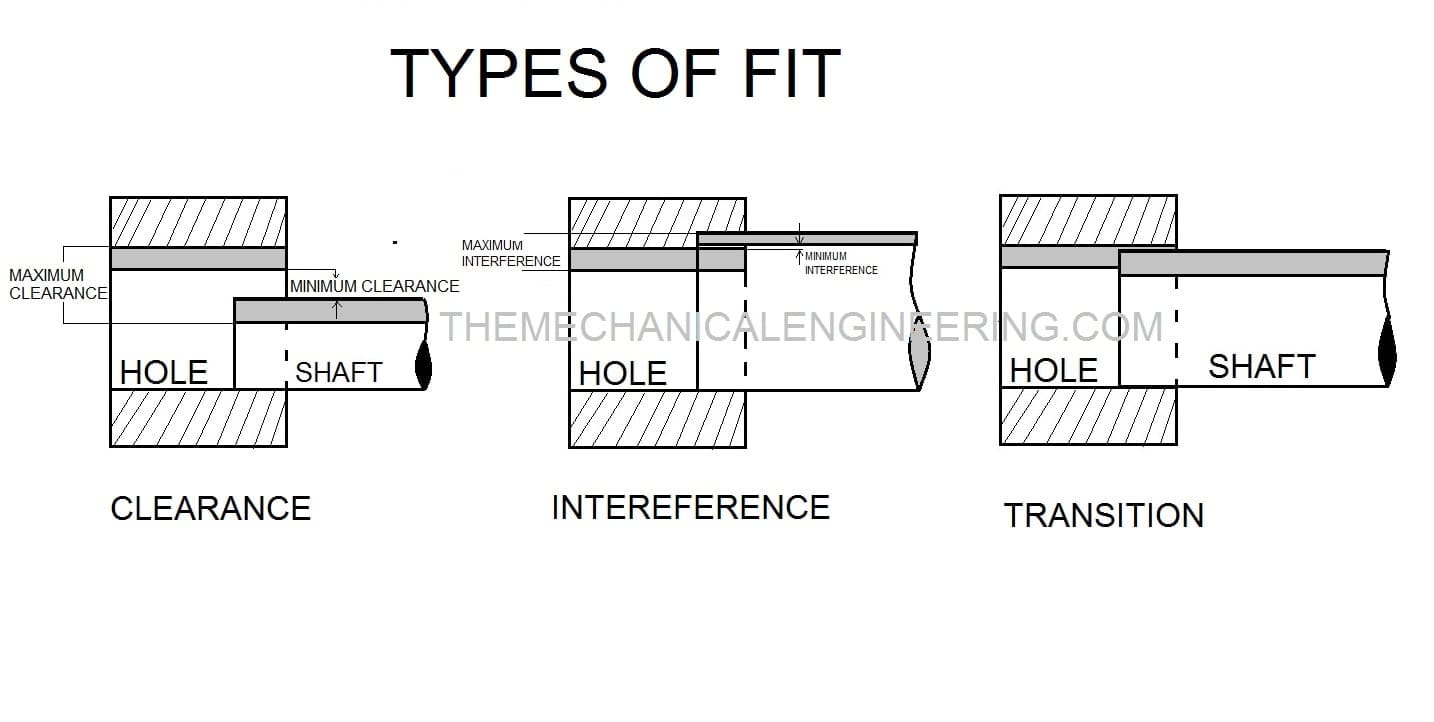

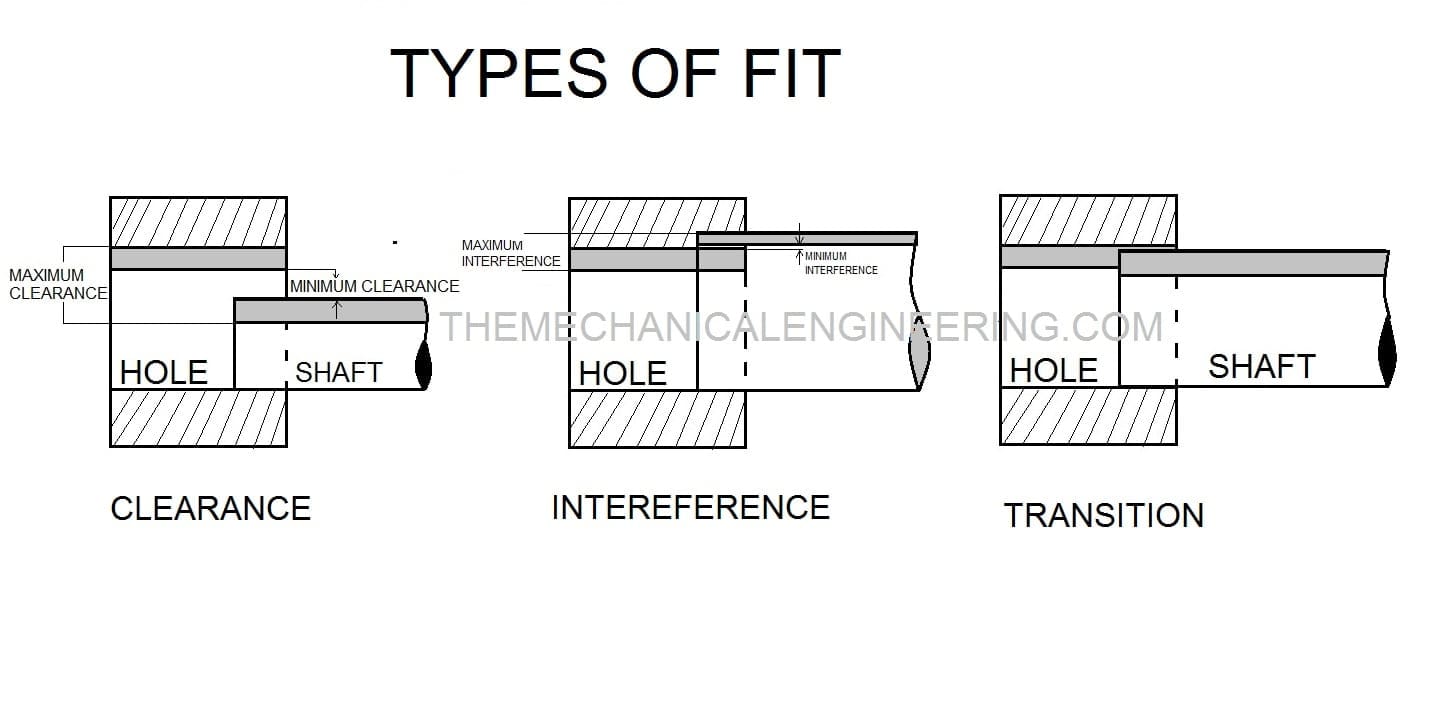

There are mainly three types of fit and those are:

- Clearance Fit

- Interference Fit and

- Transition Fit

Now we will try to study these three in detail.

Clearance Fit:

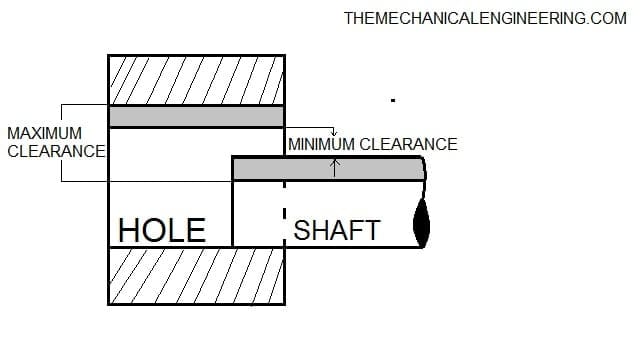

The clearance fit has a hole and a shaft in which there are upper and lower limits. Inside the hole along with these both come in the tolerance zone.

What is the Tolerance zone?

Suppose we have to make a 10 mm nut for a 10 mm bolt. But due to human and machining error, the diameter inside it became 9.98mm. Therefore the nut will not fit in the bolt and our joint will be spoiled. So tolerance zones are used to avoid this error.

We define a range in the tolerance zone, where the tolerances of nuts and bolts are a little bit even then they become fit and to keep the interchangeability Between two parts.

Now come to Clearance fit,

In this, the tolerance zone of the hole and the tolerance zone of the shaft, there is a lot of gap between them.

So if the hole is larger than the shaft and to allow the two mating parts to rotate or slide over each other, we call it clearance fit.

In the case of clearance fit the minimum size of the hole will always be greater than the maximum size of the shaft.

In any case, when we assemble the shaft and hole we are going to get the clearance that is a shaft can easily slide and at the same time, it can rotate inside the hole.

So we can easily make running fits and sliding fits in the clearance fits. Example: Piston and valve.

Types of Clearance Fit:

There are five types of clearance fit:

- Slide fit

- Running Fit

- Loose Running Fits

- Easy Slide and

- Location clearance fit

Slide fit:

It has very little clearance between two parts which we say almost to zero but it provides very greater precision and accuracy in sliding and moving parts.

Example: Sliding gears, automobile assemblies, slide valves, clutch discs, parts of machine tools, tailstock spindle of the lathe machine, guiding of shafts, etc

Running Fit:

For rotation of components at a moderate speed, the running fit has to be employed where accuracy is not necessary.

Running fit has large clearance and it involves large temperature variations, high running speeds, and heavy journal pressures. Example: Gears, coupling, etc.

Loose running Fits:

Loose running fits are employed for rotations at high speeds of the parts and have a larger clearance where accuracy is not important.

Example: Latches, pivots, heat, parts affected by corrosion, contamination, etc.

Easy slide:

Easy slide employed for small clearance between the hole and shaft. The easy-slide has been used for non-regular motions and for slow regular motion. Example: Piston.

Location clearance fit:

It provides very close and minimal clearance for the accurate precise requirement and with the help of lubrication, parts can be assembled without force and turn and slide free properly. Example: Guiding of shafts, roller guides, etc.

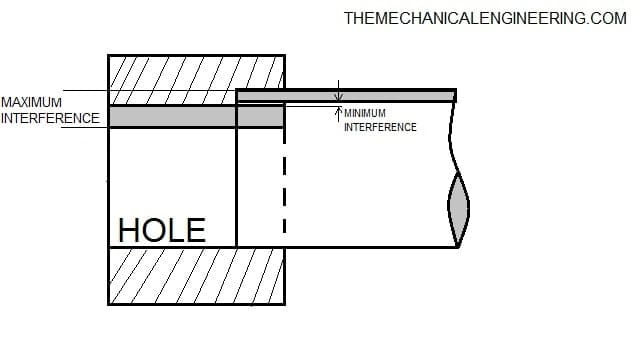

Interference Fit:

In Interference Fit, the tolerance zone of the shaft goes above the tolerance zone of the hole. This means the shaft here is of large size, and the hole is of small size.

To make the fits between these two, we required high force to assemble and disassemble so generally we use a hammer. Another way is by using hydraulic press we can fit the shaft into the hole.

Another way is to heat the hole and put it in the shaft and let it cool, then it will shrink together and it will join each other.

It is tighter than the clearance fit. It is also known as a friction fit or press fit because to join the components it needs to be some external degree of force.

Types of Interference Fit:

There are three types of Interference fit:

- Force Fit

- Tight Fit and

- Shrink Fit

Force fit:

To mating the high interference fit, it requires a very high temperature for heating the part to assemble the shaft with a hole. The external force is required for the mating parts.

Example: Gears, shafts, etc.

Tight Fit:

It provides minimal interference than force fits. Example: Stepped pulley of a conveyor, cylindrical grinding of a machine, etc.

Driving fits:

It requires medium interference which can be assembled by higher forces for cold forging or hot forging. Driving fits are more reliable than tight fits.

Example: Shafts, gears, bushes, etc.

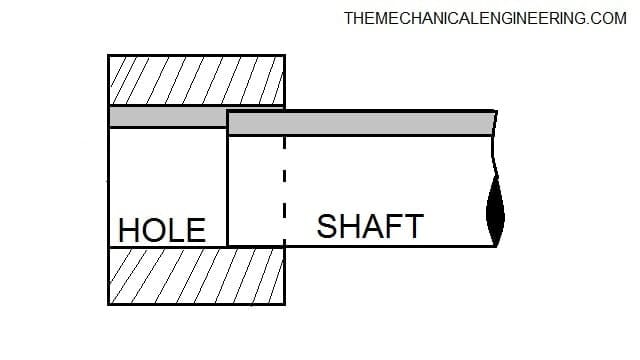

Transition Fit:

In transition fit, the tolerance zone of the shaft lies between the lower to the middle of the tolerance zone of the hole means here hole is smaller than the shaft.

So to make this fit we have to make slight pressure on the shaft to go inside the hole. We also call it Push Fits. Transition fit has great precision and accurate alignment between two mating parts. Example: Shaft key.

Types of transition fits:

- Similar fit and

- Fixed fit

Similar Fit:

It provides very negligible clearance or very small interference and assembly is achievable with using a rubber mallet. Example: Gears, Hubs, pulleys, bearing, etc.

Fixed fit:

It provides a small clearance or minimal interference fit which can be assembled or disassembled using light pressing force. Example: Driven bushes, armatures on shaft, plugs, etc.

Types of Fit Animated Video:

Internal Resources:

- Braking System Types

- Single Plate Clutch

- Multi-Plate Clutch

- Drilling Machine

- Shaper Machine

- Planer Machine

- Slotter Machine

- Grinding Machine

- Punch Press Machine

- NC Machine

Reference [External Links]:

So finally our topic ends here. Do let me know your thoughts on this topic Fit and Types. If you like the article then please share it with your friends and family.

Discussion about this post