Hello, Today in this article I will cover all the information about Punch Press Machine in very detail.

Note: If you want a PDF, You can download it at the end of the articles.

So, let’s get started with what is Punch Press?

What is the Definition of Punch Press Machine?

A punch press machine is used in the deformation of metal by applying pressure to the die attached to the workpiece. The main functions of the punch press are punching, notching, piercing, slotting, and perforating.

The punch press uses its transmission structure to produce appropriate pressure and kinetic energy near the bottom dead center along with the die resulting in plastic deformation of the workpiece according to the desired shape.

A punch press is used when the raw material is too hard to cut manually. Then a manufacturer may use a punch press.

The principle of punch press working is converting the circular motion into the straight-line movement.

It can be small and manually run or, it can be a large CNC-operated automatic machine.

Did you know? The paper punching machine you use daily works on the same principle.

Now moving to different parts of this machine,

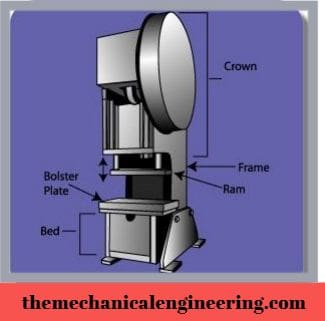

Parts or Construction of Punch Press Machine:

The following different Parts of the Punch Press Machine is:

- Base or Bed

- Frame

- Ram

- Pitman

- Driving Mechanism

- Controlling Mechanism

- Flywheel

- Brakes and

- Bolster Plate

Base or Bed:

The base or bed is the lower part of the frame and one of the most significant components of the punch press as it provides support to workpiece holding dies and different controlling mechanisms of the press.

The size of the workpiece that can be operated depends on the size of the base. In some unique cases, the bed carries a tilting mechanism for the frame.

Frame:

The frame is responsible for supporting the structure of the press. It provides support for the ram driving mechanism and controlling mechanism.

The frame is divided into two parts, the upper part known as the crown and the lower section known as the bed.

Ram:

This is the prime operating part of the press as it works directly on the workpiece. The ram moves up and down between its guideways with a predetermined stroke length and strength.

This up and down motion is known as the stroke. The crown contains a power mechanism or motor that supports the up and down movement of the ram.

You can adjust the stroke length and the strength of the ram as per requirements. The punch is attached at the bottom of the ram.

Pitman:

Pitman is the part that connects the ram and crankshaft.

Driving Mechanism:

This uses a crankshaft and eccentric mechanism to drive the ram by providing power from the motor to the ram.

Controlling Mechanism:

These are used to operate the press under calculated control conditions. The controlling mechanism adjusts two mechanisms that are the length of the stroke of the ram and the power of the stroke of the ram.

Power transfer can be disengaged using a clutch included in the driving system. Now microprocessors are used to guide the operation of the machines. These presses give reliable and accurate control with automation.

Flywheel:

This is the energy storing device of the press. It is responsible for maintaining the constant speed of the ram and avoiding fluctuations.

Brakes:

Brakes are the most crucial part of any mobile system as it helps to avoid accidents. Generally, this machine uses two brakes, a standard brake which brings the driveshaft to rest quickly by disconnecting it from the flywheel.

And an emergency brake is located at the foot of any machine. These include normal stronger braking with a power shut switch.

Bolster Plate:

It is a thick plate attached to the base of the press to clamp the bottom part of the die.

Types of Punch Press Machine:

Punch Press Machine has been categorized into two types:

- According to driver types and

- Slider Movement.

According to the Drive types:

This has been categorized into four types:

- Flywheel Drive

- Mechanical Drive

- Hydraulic Drive and

- Servo Drive

Flywheel Drive:

Today most of the punch press machines are hydraulically powered but, in older days, A heavy constantly rotating flywheel provided power to the ram.

Using the pitman’s arm, the flywheel drives the ram. In the 19th century, the flywheels were driven by a leather drive belt attached to the line shafting. In modern operation, an electric motor is used to power the punching press machine.

Mechanical Drive:

These are the most commonly used punch presses. There are two types of mechanical punch presses based on the clutch or braking system they hold. Usually, older presses are full revolution presses that require a complete revolution of the crankshaft to stop the operation.

Full revolution clutch presses are hazardous and prohibited in many countries unless the pinch point is fully secured. A set of elevated keys or dogs are responsible for stopping the ram.

A complete revolution press can pause the ram at the top dead center. Newer presses are the half or partial revolution presses having brakings system similar to commercial trucks.

Applying the stopping mechanism reduces the air allowing the clutch system to shut and the brake system to open, resulting in effectively stopping the ram at any point of its rotation.

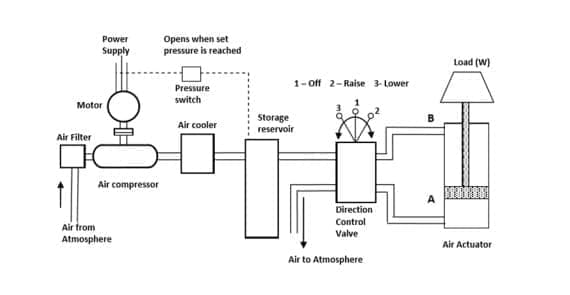

Hydraulic Punch Press:

These punch presses use a hydraulic cylinder rather than a flywheel to power the ram. And controlled by valve or feedback and valve. These valve-operated presses perform one stroke operation which means the ram will move up and down when commanded.

A controlled feedback system enhances the punching rate and provides higher control on the ram and, now the ram can function in a short window of stroke.

Servo Drive Turret Punch Press:

In this system, the original brake & clutch technology is combined with the hydraulic ram operated system. This reduces the operating cost and enhances reliability and performance. This system has a lower maintenance cost as it does not have hydraulics or an oil-cooling chiller. If a turret press can be provided with superior technology that stores and reuses the energy produced during ram deceleration can help in saving electricity.

According to slider movement:

This divides the punch presses into three types single action, double action, three action presses but most commonly used among these is a single movement punch press. Double and three actions are generally used in producing the car body and large-scaled parts.

Working Principle of Punching Press Machine:

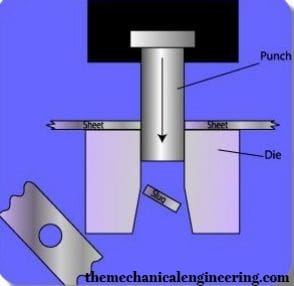

The punching press works on the principal conversion mechanism that converts the rotary motion to linear motion.

The main motor provides the power to drive the flywheel.

With a clutch and connecting rods, the flywheel drives the crankshaft or the eccentric gear.

To convert the circular motion to the linear motion. There is the need for a transfer point between the slider and the connecting rods.

There are two types of designs to convert circular motion into linear motion one is the spherical type. And another is a pin or cylindrical type.

During the operation, the drive mechanism powers the rams up and down movement.

This action opens and closes the upper die & lower die shoes.

During the operation, a sheet metal strip passes between the die shoes.

And finally, when the punch (ram attached with the die) moves down, applies pressure on the metal sheet and cuts a hole.

The detached portion falls from the opening of the die.

Punch Press Machine Working Video:

Advantages of Punch Press Machine:

There are the following advantages of Punch Press Machine:

Stable And High Precision: The equipment of the punch press such, as crankshaft, gear, ram are made in high heat that harden the equipment and provide stability and high wear and tear resistance.

Reliable and Safe Operation: These machines come in two types of brakes one normal and the other is an emergency brake which helps to stop the machine in an emergency. Now as the technology advances these machines come with advanced sensors to provide safe operations.

High productivity, reduce labor work, and automatic production: These machine provides higher productivity and reduces manual labor results reducing the cost and increasing efficiency. Now as technology advances this machine has a fully automated process that does not require manual labor.

Disadvantages of Punch Press Machine:

There are the following disadvantages of Punch Press Machine:

- These machines require generally higher investment.

- Produces loud noise.

- Complex parts are involved it requires an expert for a small error also.

- Not suitable for small-scale production.

Application of Punch Press Machine:

The following application of Punch Press Machine:

- Punching Press Machines are used in many industries but specifically in the metalworking industry.

- The punching press machine is used to manufacture different products in industries by making the hole in the workpiece used in automobiles, aerospace, manufacturing industry, defense equipment, etc.

- The punching press machines are also used in the food and restaurant industry to cut chapati, puri, papad from the atta sheet.

- A type of punching press we also use in our homes to punch papers.

Internal Resources:

- Milling Machine

- Drilling Machine

- Shaper Machine

- Slotter Machine

- Lathe Machine

- NC Machine

- Hot Working Process

- Cold Working Process

Conclusion:

Punching Presses are an important element of manufacturing that helps the manufacturing industries in metal cleaning and producing processes. There are different types of Punching presses like hydraulic, mechanical, servo drive, etc.

I hope, this article has helped you to get a clearer view of the Punching press and its working and applications. Please comment on all the queries regarding this article.

Discussion about this post