Hello, In this article we will study Propeller Shaft and its subtopic like Definition, Characteristics, Construction or Parts, Types, Material, Advantages, Disadvantages and Application in detail.

Note: At the end, I have attached a PDF, which you can easily download.

The term drive shaft was used in the mid-19th century for the first time. In 1861 Watkins and Bryson patented the term for a mowing machine where the shaft was used to transmit power from the wheels of the mowing machine to the cutting machine using a gear train.

In the 1890s the term drive shaft became quite common. In the year 1899 Bukey used this term for power transmission from wheel to the driven machinery using universal joints.

The first use of drive shaft also known as propeller shaft in the automobile was done in the year 1901 by an automobile company in a gasoline car.

Now we will study the definition,

What is Definition of Propeller Shaft?

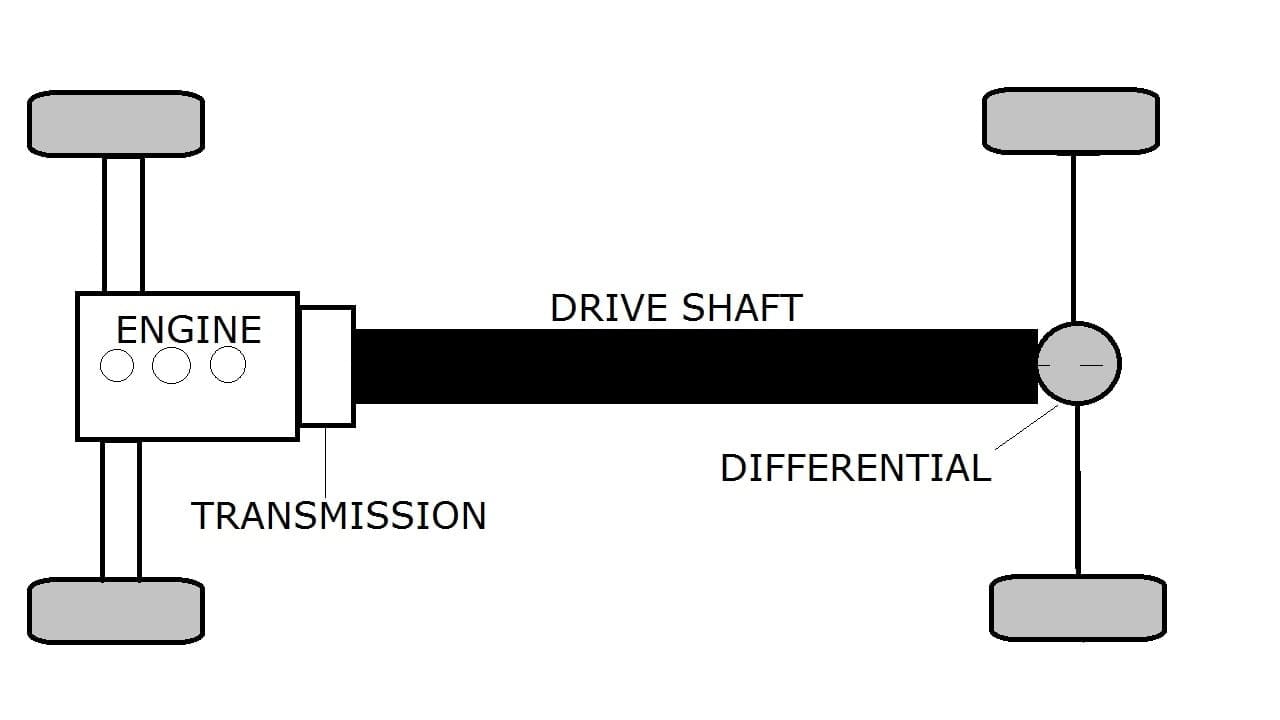

The component which is used to transfer torque from the gearbox to the rear axle or differential is called a propeller shaft. It is not only used in cars but is also used in boats and aeroplanes. It is also known as the Cardan shaft or drive shaft.

The propeller shaft is a hollow tube-like structure with a combination of universal and slip spline joints. In most cars except the modern-day cars, the engine is situated at the front end and it is used to drive the rear wheels.

Hence, The shaft is used to transmit the power from one end of the automobile to the other end. In automobiles where the front wheel is given power, a short shaft is used.

Characteristics of the Propeller Shaft:

The following characteristics are:

- The propeller shaft transmits power from the gearbox’s output shaft to the differential.

- There are no or very few power losses, this means there is no change in the RPM when the power is transmitted.

- It can transmit power at a different elevation like if the gearbox output shaft is at 1 meter from the ground and differential is at 0.5 meters from the ground.

- The shaft can adjust itself while the vehicle runs through obstacles such as a speed breaker.

Construction or Parts of Propeller Shaft:

A propeller shaft consists of three main components:

- Universal joints

- Split spline joints and

- Tubular shafts

Let’s understand one by one in detail,

Universal joint:

A universal joint is the most important component of a propeller shaft there are two universal joints in a single-piece propeller shaft. The number of universal joints can be up to three or four depending on the type of propeller shaft.

A universal joint is that component that allows rotation of the propeller shaft on various axis. It is a flexible joint that compensates for the elevation difference between the gearbox output shaft and the differential.

Slip spline joint:

A slip spline joint is generally used at the output side of the propeller shaft. It helps in torque transmission at various lengths of the propeller shaft. It comes in action during the obstacles faced by the automobile.

For example, when a car approaches a speed breaker the rear wheels will be pushed up this results in compression of the propeller shaft as soon as the car passes the breaker the dampers push back the rear wheel which results in the normal length of the shaft.

To transmit power during such conditions a slip spline joint is used. It also protects the shaft from compressive and tensile stresses.

Tubular shaft:

The tubular shafts are used to compensate for the distance factor between the gearbox and the rear axle. There can be two or more tubular shafts depending on the type of propeller shaft.

The tubular shafts can be short as well as long depending on the distance from the gearbox to the axle. In the case of a rear-wheel drive, long tubular shafts are used and in the case of a front-wheel drive, short tubular shafts are used.

The tubular cross-section provides better strength and flexibility and is lightweight when compared to a filled cross-section.

Flange yoke:

Flange yoke is the first connecting member which connects the whole drive shaft assembly with the gearbox.

Bearings:

There are present at many rotational joints in the shaft. The function of bearings is to reduce friction and reduce heat generation.

Propeller Shaft Working Video [In Hindi]:

Working Animated Video:

Types of Propeller Shafts:

There are two basic types of propeller shaft:

- Single piece or one-piece type and

- Two-piece type propeller shaft.

Single piece type propeller shaft:

In this type, there are two universal joints, one slip spline joint, and one tubular shaft. It is used for short-distance transmission.

Such as cars and is also used widely for front and four-wheel drive. It provides better strength to the arrangement. It is more durable than a two-piece type propeller shaft this is due to the friction welding at the junctions.

Two-piece type propeller shaft:

There are three universal joints, one slip joint and two tubular shafts in the arrangement of two-piece type. It is used for long-distance transmission. Such as busses and trucks.

The strength factor is less due to the increased number of joints. It is less durable as friction welding is not done. The torque transmission is less than that of a single piece.

Materials used for making Propeller Shafts:

The following material can be used for making Propeller shaft are SM45C steel, Epoxy composite material Alloys of aluminium and stainless steel, SAE1045 steel, and Kevlar epoxy.

SM45C steel:

SM45C is a low-carbon high-quality structural steel. The wear resistance of this material is high which is a requirement for the propeller shafts. It is a quenched and tempered form of steel. The tensile strength of SM45C is greater than 600MPa.

Epoxy composite material:

Propeller shafts are also made of epoxy composite materials mainly carbon epoxy composites. These have a high tensile strength varying from 800-1300 MPa. These materials are ideal for making high-precision tubes.

Alloys of aluminium and stainless steel:

Different alloys of aluminium and stainless steel are used for making propeller shafts as they are strong and can sustain the torsional vibrations. The tensile strength of aluminium alloys is also high.

SAE1045 steel:

SAE1045 is high-quality steel with a tensile strength varying from 570-700MPa. It has good machinability and weldability. It is widely used for making propeller shafts in various automobiles.

Kevlar epoxy:

Kevlar epoxy is another material that can be used for making propeller shafts.

It is an uncommon material for propeller shafts as studies are still in progress on this material.

Although a simulation-based study says that Kevlar epoxy serves as a better material than the conventional materials used for making propeller shafts as it is lighter and stronger.

Requirement of a Propeller shaft:

The following requirement is:

- Lightweight: it must be lightweight to ensure the proper weight of the vehicle.

- Thermal resistance: the material used must not show high variations in physical properties under increased temperature.

- High torsional strength: the propeller shaft must have high torsional strength to survive under high torque conditions.

- Damping quality: there are many variations that a propeller shaft has to face hence it is important to have a damping quality to absorb vibrations.

Advantages of Propeller shafts:

Following advantages of Propeller shaft:

- Low or no power losses.

- The weight of the shaft is less due to the tubular structure.

- Construction is not very complex.

- Ensures safe power transmission.

- Low noise at high torques.

- It is durable.

Disadvantages of Propeller shaft:

Following disadvantages of Propeller shaft:

- May damage if the RPM is too high.

- Hollow propeller shafts are costly.

- They are not very strong

- Not suitable to counter bending forces.

- There may be an oil leakage problem at the spline.

Applications of Propeller shafts:

Following application of Propeller shaft:

- Propeller shafts are used in constructional motor vehicles.

- They are also used in various heavy-duty machines.

- Propeller shafts are widely used in commercial automobiles.

- It is also used in ships for providing power to the propeller.

- It was also used in old airplanes.

Related Resources:

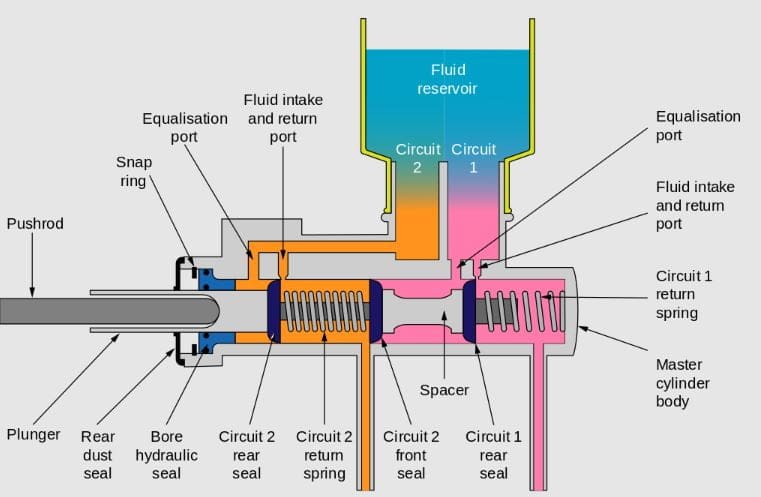

- Braking System Types

- Single Plate Clutch

- Multi-Plate Clutch

- Clutch complete Notes

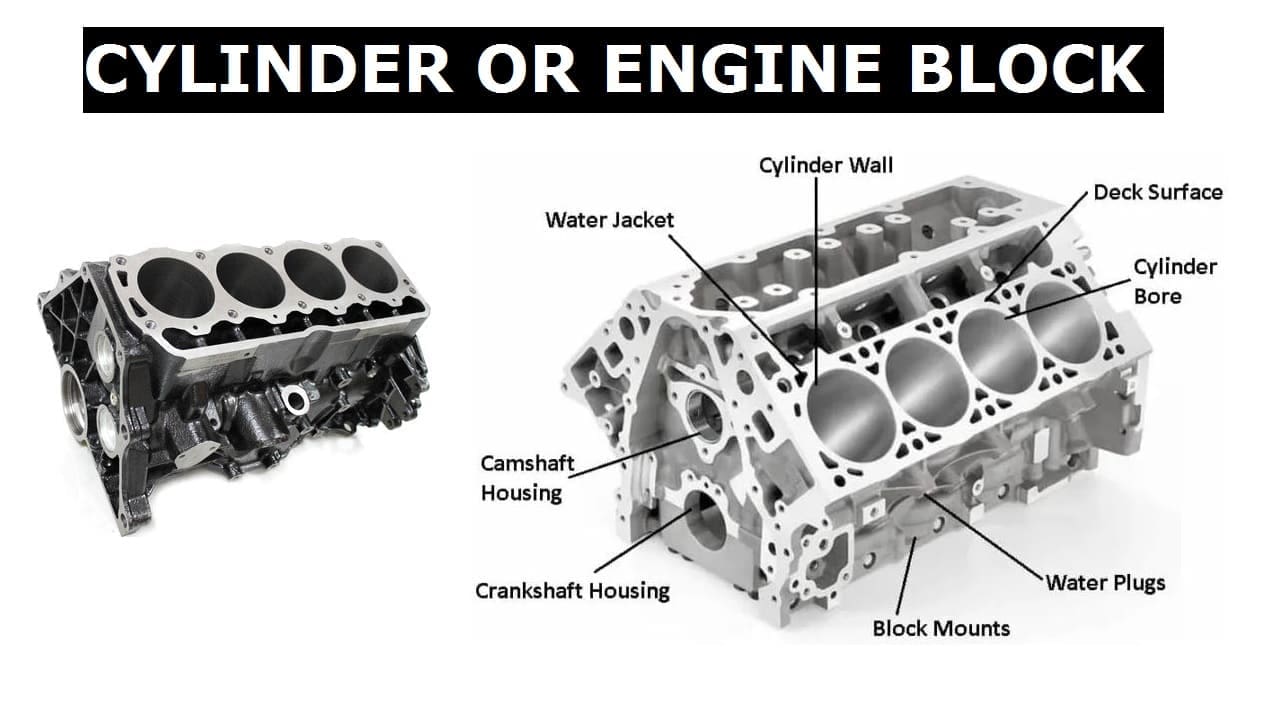

- Cylinder Head

- Cylinder Block

- Electronic Ignition System

- Battery Ignition System

- Magneto Ignition System

- Lubrication System Types

Reference:

- https://www.sciencedirect.com/topics/engineering/propeller-shaft

- https://www.youtube.com/channel/UCl0qZwRZEI68jRmT65-_BIA

- https://www.youtube.com/channel/UCNrYkkIkpj3Z0o98LWVHg5g

Conclusion:

So here we have studied the Drive shaft in detail. Let me know what else I can help you in this topic or any other topic?. You can check our another article I am sure that can boost your knowledge. Till then Thank you for reading.

Discussion about this post