In this article, we will study the Definition, Parts or Construction, Working Principles, Advantages, Disadvantages, and Application of Multi Plate Clutch in detail.

Note: At the end of the article you can easily download whole articles in PDF format.

Let’s start with the definition first,

Multiplate Clutch Definition:

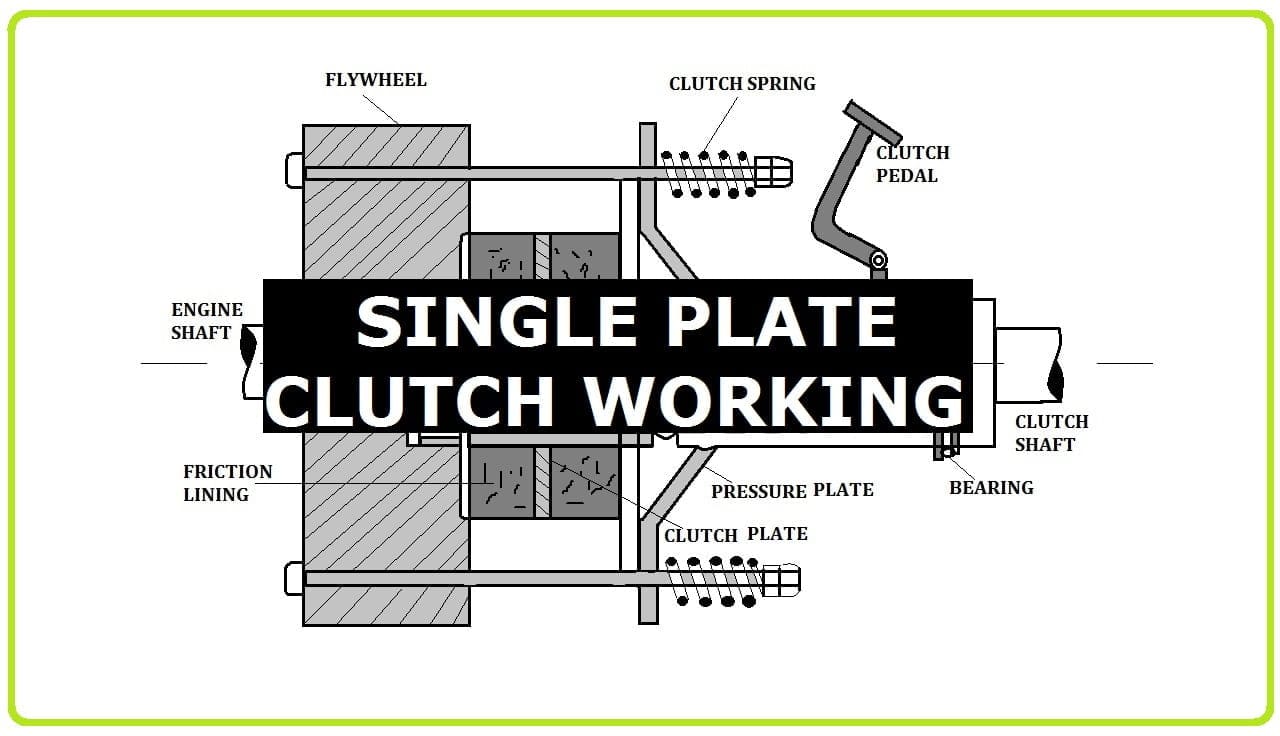

Multi-Plate Clutch is part of the transmission system as it is used to transmit the power from the engine shaft to the transmission or driven shaft for the drive to the required torque or speed required for the Output.

Multi-Plate Clutch is needed for high torque output like in trucks used for pickup Whereas a Single plate clutch will fail to provide that much frictional force between Flywheel and clutch plates.

Multi-Plate Clutch consists of a number of clutch plates that’s why it is called Multi-Plate clutch but in Single plate clutch, there is only one clutch plate.

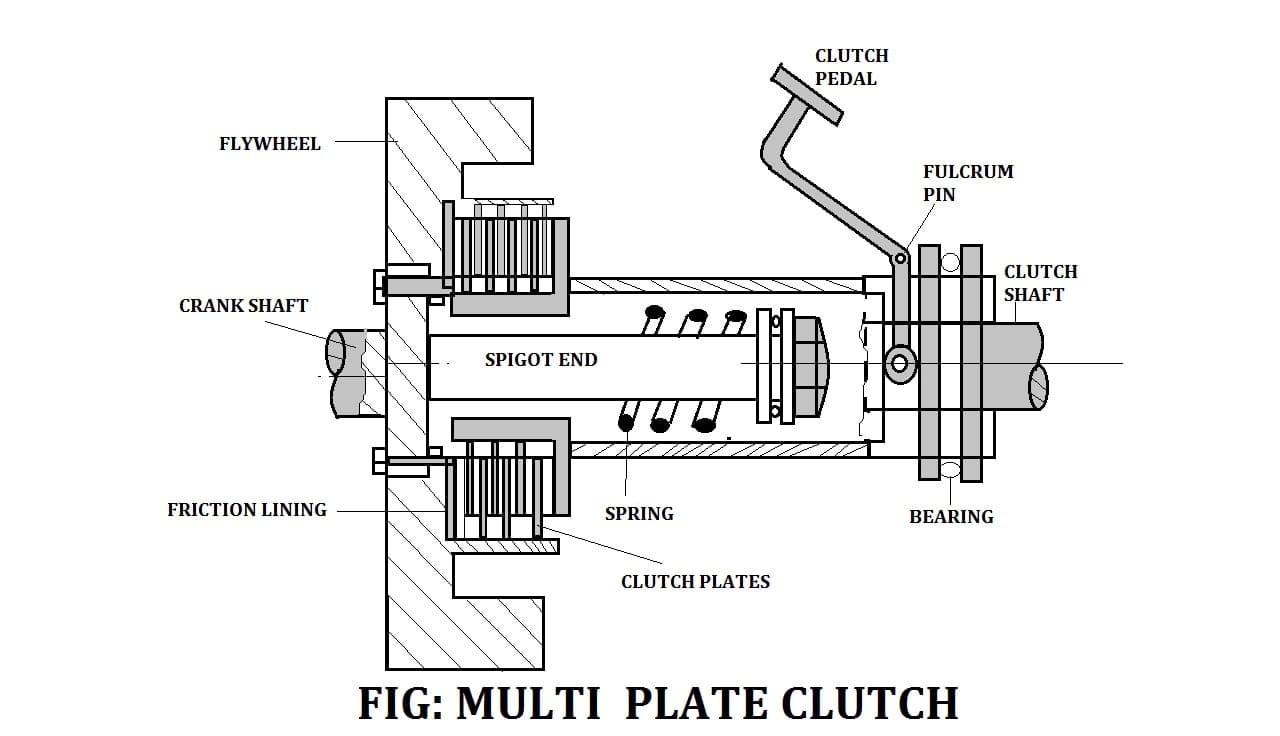

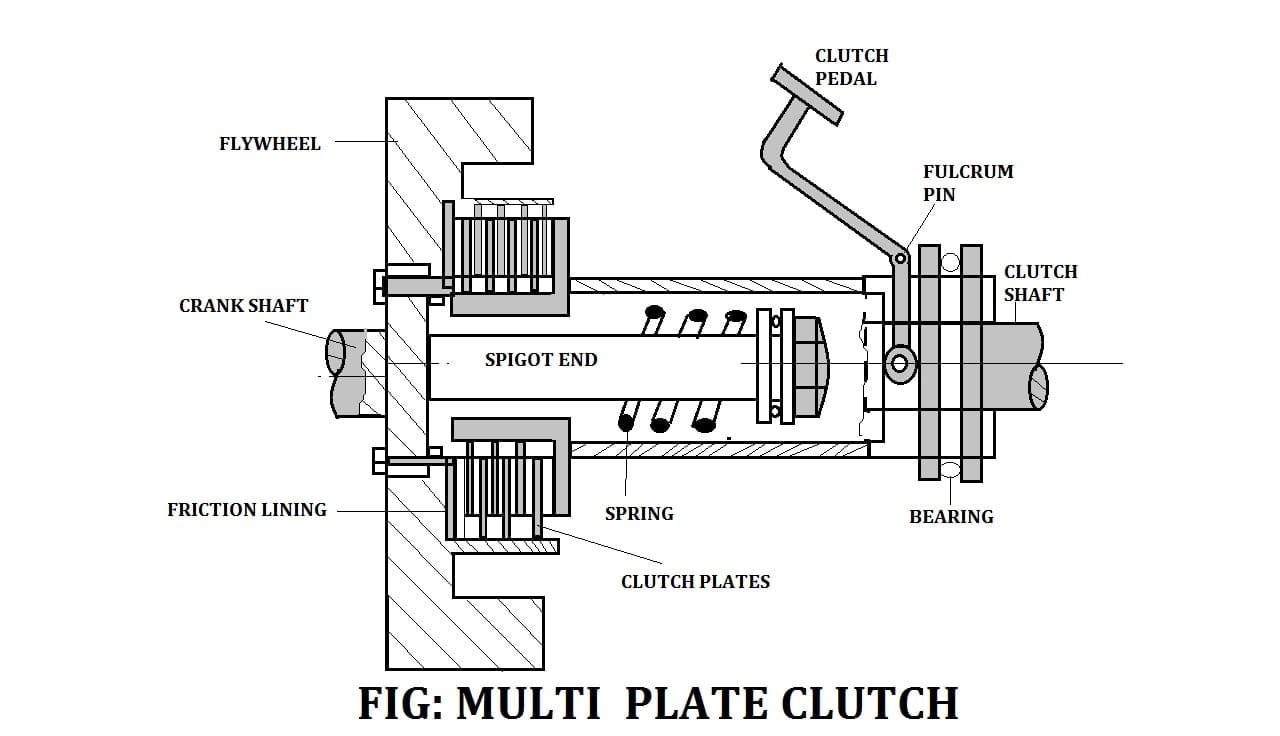

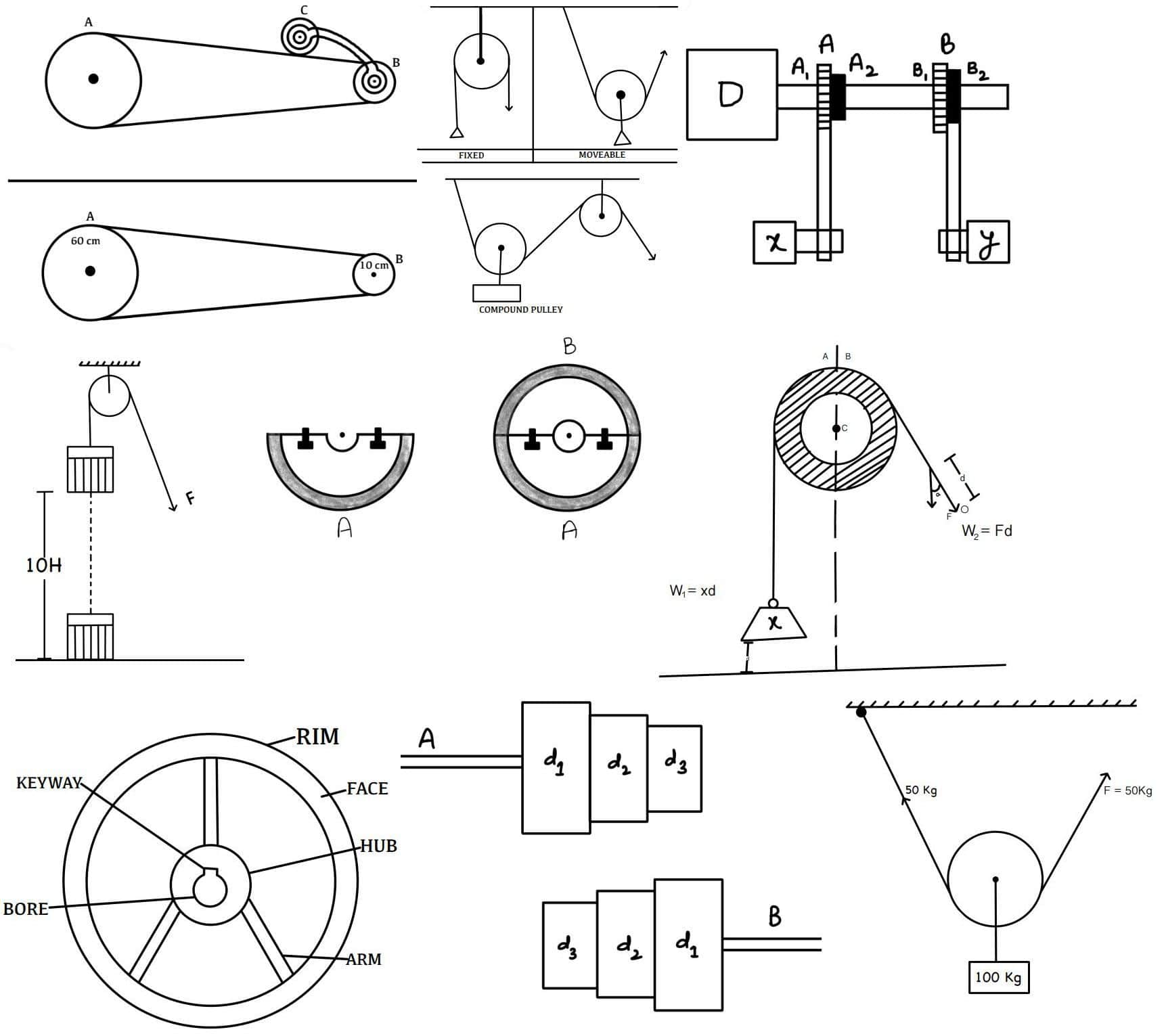

Multi-Plate Clutch Construction or Parts:

The construction or Main Parts of Multi-Plate clutch are:

- Flywheel

- Pressure plates

- Clutch hub or Inner hub

- Clutch Pedal

- Steel plates or Driven Plates

- Friction plates or drive plates and

- Clutch springs

Flywheel:

The flywheel is an important part of the engine and also a clutch system. The power transmission from the engine output shaft to the transmission shaft is obtained by the frictional contact between the clutch and the flywheel of the engine. It transmits generated power from one shaft to another shaft.

Pressure Plates:

The Pressure Plate is mounted on a splined shaft so that it can slide back and forth. The Friction discs are bolted to the pressure plate. Its sliding is controlled by the clutch pedal.

Clutch hub or Inner hub:

It is a rotating part attached to spline parts that provide torsional dampness. It has the pinion gear and the axle drive that is mounted on the axle housing and rested on the tapered bearings.

For this purpose, at least one plate is attached to the spline at a proper angle for the smooth functioning of the clutch.

Clutch Padel:

A clutch pedal modulates or amplifies the clutch mechanism with help of a clutch pressure plate. Our foot will press the clutch pedal to engage and disengage the clutch with the help of the spring and pins mechanism. It pulls the pressure plate away from the clutch plate.

Steel plates or driven plates:

It is made up of non-corrosive steel material. The steel plates have the lugs or projection on the inner diameter that have the main function to control the power transmission of the input shaft.

It is the main part of the clutch that decides the functionality of the clutch. If the clutch overheats, the steel plates become discolored and it is a sign that it should be replaced.

Friction plates or drive plates:

A friction Clutch plate is used to transmit the input shaft and the engine at the same rotating speed. When the clutch is engaged friction plate is sandwiched between the flywheel and the pressure plate.

Friction should be sufficient so that there will be no slippage. mostly friction plate is made up of asbestos.

Clutch springs:

It is used to engage or disengage the clutch mechanism and store the torque energy and give back when required. Clutch springs are of two types coil clutch springs and tension clutch springs.

They are also used in clutch dampers to control the vibrations produced during engaging and disengaging.

Multi-Plate Clutch Working Principle:

In 2 wheeler vehicles as in bikes and scooters there is the problem of packaging due to that small size of them, So to get the required output, instead of a large single plate Clutch, A multi-plate Clutch having small clutch plates is used to transmit power between engine shaft and the transmission shaft.

When there is the gradual Engagement of the clutch in order to transmit power between the Flywheel and the driven shaft multiple plates of multi-plate clutch provide more frictional force between the Flywheel and the pressure plate as compared to single plate clutch

Due to this, the chances of slip are almost zero or negligible in the multi-plate clutch which is helpful in getting a required mechanical advantage.

For example, anti terrain vehicle ATV has different ups and downs or different road challenges like in our college’s competition held named BAJA SAE.

A multi-plate clutch is required to maintain the smooth and steady Engagement between the engine and the driven shaft that continuously provides the required amount of torque and speed to the driven shaft.

The efforts required by the driver on the clutch pedal in order to engage or disengage the clutch are less in the multi-plate clutch as compared to a single plate clutch.

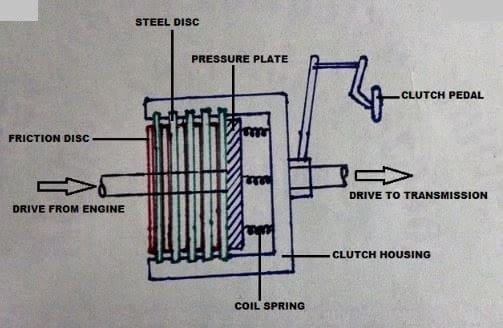

A multi-plate clutch consists of a number of clutch plates, instead of only one clutch plate as in the case of the single-clutch plate. The increased number of friction surfaces obviously increases the capacity of the clutch to transmit torque.

The plates are a fit to the engine shaft as well as the gearbox shaft in between.

Each of the alternate plates slides in grooves splines on the Flywheel and the other slides on splines on the pressure plate. Torque Transmitting capacity is more but heat generation is more & Coefficient of friction is low.

When the Clutch pedal is not pressed the thrust springs will not move forward due to which the stiffness provided by the springs maintains the pressure over the pressure plate that has friction lines on its inner surface.

Due to this pressure over the pressure surface, the frictional contact between the friction lines of the pressure plate and the friction lines of multiple clutch plates is maintained due to which frictional force is applied over the Flywheel.

Due to this frictional force, the frictional contact between the multiple clutch plates and the Flywheel is maintained which in turn finally provides clutch engagement.

When the clutch pedal has pressed the fulcrum is attached at the inner side and rotates due to the inner splined sleeve through which the pressure plate is attached moves outward which in turn applies pressure over the thrust springs.

Due to this force, the trust springs move which in turn releases pressure over the pressure plate, and finally, the frictional force between pressure plates, clutch plate, and the Flywheel is removed.

In a multi-plate clutch, the number of frictional linings and the metal plates is increased which increases the ability of the clutch to transmit the rotational force or ability of the force to rotate.

The rings of friction are splined on the outer circumference and Engaged with splines on the Flywheel. They are free to slide in the axial direction the friction material thus rotates the flywheel which will transmit the torque.

The driven shaft can also support discs on the splines which also rotate with the driven shaft and can slide axially. If the action force on the pedal is removed or released a spring presses the discs into contact with the friction rings and the torque is transmitted between the driveshaft and the driven shaft.

If n is the total number of plates both the driving and the driven members the number of active surfaces will be n-1 because there is one line or surface common.

Multi Plate Clutch Video:

Multi-Plate Clutch Types:

There are three types of Multi-plate Clutch:

- Spring type Multi-plate clutch.

- Diaphragm Type Multi-plate Clutch and

- Hydraulic Operated or Automatic Clutch.

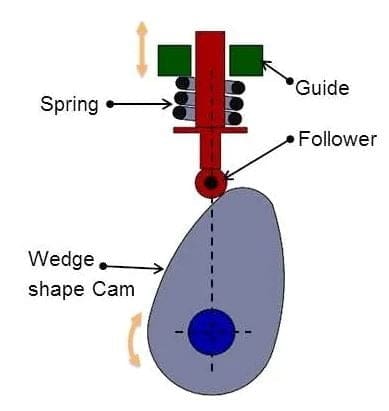

Spring Type Multi-plate Clutch:

This type of clutch is used in old cars and bikes. In this type of clutch, a cover is attached with the Flywheel of the engine and it is used where the multiple clutch plate of pressure thrust bearing are of packing type the clutch, plates are attached over each other and placed on the splined shaft

It also has a pressure plate which is used where it is having an outer sleeve connected to the pedal fork in such a manner that pressing of the pedal will move the pressure plate outward direction in order to disengage the clutch so as to perform the operation of the clutch

This pressure plate used is made in touch with the clutch plate in order to engage the clutch and the release of the contact will give disengagement of the clutch

The Engagement of the clutch is performed by the stiffness of the spring which should be enough to deal with the load that it will exert on the transmission body and also provided by the number of thrust springs placed in a circle which is used behind the pressure plates due to the compression of these thrust springs disengagement of the clutch occurs.

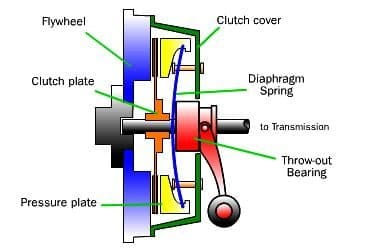

Diaphragm Type Multi-plate Clutch:

Used in modern cars and bikes. It is the change version of spring type multi-plate clutch in which the thrust springs placed in rotation from the spring type clutch is replaced with a special crown-shaped spring called diaphragm spring

During the Engaged state of the clutch, the fingers like fins of the diaphragm clutch will be in floating type mode due to which the multiple clutch plates which have friction lining on the other end attached will make continuous frictional contact with the Flywheel resulting in power between the engine Flywheel and the driving shaft.

When the driver presses the clutch in order to shift gear the force will be applied by the driver over pedal is transferred to the diaphragm spring which in turn size will decrease the fingers shape of the diaphragm spring will make disengagement of the clutch will happen.

Hydraulic Operated or Automatic Clutch:

It is one of the advanced types of clutch used in automobiles/vehicles that has an automatic transmission.

In this type of clutch Hydraulic device that has highly compressing fluid that is operated with the accelerator pedal and is coupled with the multi-plate clutch and the Engagement and disengagement of the clutch will be obtained by the output by the Hydraulic device which is controlled with the acceleration pedal.

A multi-plate clutch is the best clutch device for automatic transmission due to its high torque transmission and also due to its advantage of less input force that is needed to operate the clutch.

Multi-Plate Clutch Advantages:

The following Advantages of Multi Plate Clutch are:

- The Multi plates clutches will transmit very high torques due to the various no. of the friction linings or the friction surface.

- The size of the multi-plate clutch is quite less than the single plate clutch for the same power transmission so it is compact and used in modern vehicles where we don’t want any slippage.

- The Multi plates clutches have applications in heavy vehicles and racing cars to transmit high torque.

- The Multi plates clutches have applications in two-wheelers where there is a limitation of space.

Multi-Plate Clutch Disadvantages:

The following disadvantages are:

- Multi-plate clutches are too expensive due to no friction linings and high torque requirements.

- Multi-plate clutches are heavy due to the no. of friction lining and also due to large input of the force.

- the clutch engagement is not instantaneous.

Multi-Plate Clutch Application:

The following application is:

- Multi-Plate Clutch is used in racing motorcycles and cars.

- It is also used in heavy commercial vehicles to transmit high torque.

More Resources for You:

Reference [External Links]

This is all about Multi-Plate clutch from my side. Let me know your thoughts in the comment box. And if you like the article do share it with your friends and family.

Discussion about this post