The Cornish Boiler was invented in 1812 by mining engineer Richard Trevithick. In this article, we will study Cornish Boiler in depth.

Notes: PDF at the end you can download easily.

Let’s start our topic,

What is a Cornish boiler?

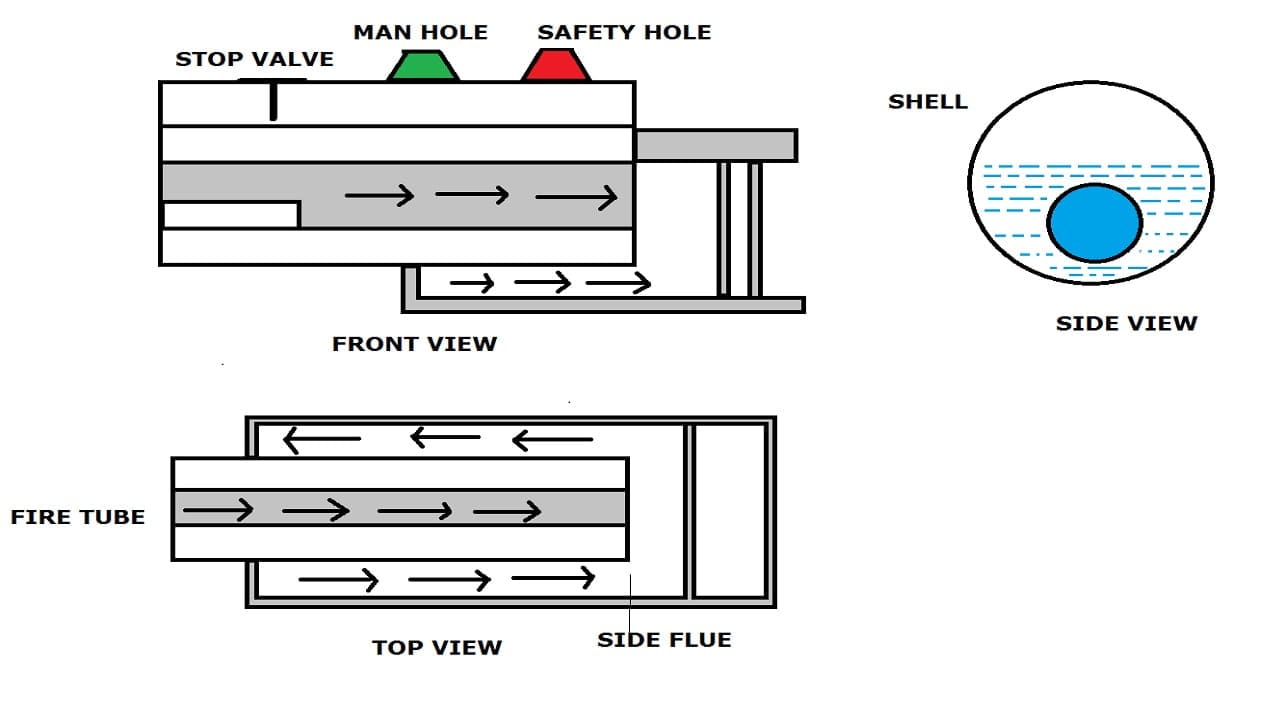

Cornish boiler is a fire-type boiler in which hot gases passing through a tube raise the temperature of the surrounding water to produce steam. It is horizontally placed. The circulation of gases is natural i.e no external force is applied here, the gases travel upwards due to low density.

The working of a Cornish boiler is similar to that of a Lancashire boiler but in a Lancashire boiler, two fire tubes are used whereas in a Cornish boiler only one fire tube is used. It is capable of producing steam at 1350 kg/hr and can take a maximum steam pressure of 11 bar.

Cornish Boiler Construction or Parts:

The cornish boiler consists of a cylindrical shell that is mounted on brickwork. The length of the shell is about 4-7m and the diameter of the cell is about 1.25 m-1.8m [Sources: Green Mechanic].

An entrance is provided known as a fire door, through which coal is inserted in the boiler.

Mountings such as safety valve, steam stop valve, and manhole are provided on the upper surface of the boiler to ensure the proper functioning of the boiler.

A pressure gauge is provided near the steam valve which indicates steam pressure.

Inside the shell, a fire tube is present around which water is there. The fire tube is located in the middle of the water surrounded area and hot gases pass through this tube.

A grate is present at the front end, on which coal is kept. An arc-shaped like structure is provided at the end of the grate which allows only hot gases to pass through the tube and prevents the entry of coal and ashes.

Spaces for the flow of flue gases are provided on either side of the tube which is known as side flues, and below known as bottom flues. The flue gases pass through these spaces to provide more heat to the water in order to increase efficiency.

The blow-off valve is located at the bottom left corner of the shell.

The main components of a Cornish boiler are as follows:

- Safety Valve

- Side flue and Bottom flue

- Manhole

- Steam stop valve

- Water level indicator

- Grate

- Firetube

- Shell

- Blow-off valve

- Ash pit

- Chimney

Safety Valve:

It prevents the buildup of excess pressure inside the boiler. As soon as pressure exceeds the maximum limit, the safety valve opens and lets it escape to the atmosphere. A safety valve is extremely important because of the high-pressure environment inside the boiler.

Side flue and Bottom flue:

They are spaces provided at the side and bottom of the fire tube to enable the hot flue gases to pass through and increase the temperature of the water.

Manhole:

To maintain the cleanliness of the boiler, a manhole is provided at the top. A person can enter inside through the manhole and usually once or twice a year, clean the entire boiler. Maintenance of the boiler is essential because salt is sometimes deposited in the boiler.

Steam stop valve:

A steam stop valve is used to regulate the flow of steam. The valve is initially closed. When steam pressure exceeds a certain limit, the valve opens and expels the excess pressure into the atmosphere.

Water level indicator:

The water level indicator indicates the level of water in the boiler. It sends a signal when the water level is too high or too low. It consists of equal spacings so that air can enter and proper combustion takes place.

Grate:

The grate is a framework of metal bars on which coal is kept. It is located at the front end of the boiler. It is generally made up of cast steel.

Fire tube:

A fire-tube is a long, horizontal tube that is located in the middle of the surrounding water area. Flue gases pass through it.

Shell:

It is the outermost part of the boiler which consists of the fire tube and water surrounding it. A shell also acts as structural support.

Blow-off Valve:

It is located at the bottom left corner of the boiler and is used to discharge dirt and impurities from the boiler during a maintenance check.

Ash pit:

It is a small chamber located below the grate used to collect the ashes developed by the burning of coal.

Chimney:

It is a vertical pipe located at the back end of the chimney. Flue gases are released into the atmosphere via the chimney.

Cornish Boiler Working Principle:

A Cornish boiler works on the principle of Thermal conduction, that is hot gases emerging from the combustion of fuel with air pass through a fire tube and transfer the heat to the surrounding water by thermal conduction. This heat increases the temperature of the water to the extent to which it starts boiling.

Note: thermal conduction is a microscopic process in which a particle carrying energy transfers it to the nearest particle by collision.

Step by step Working in brief:

Fuel is inserted through the fire door and placed over the grate, and burnt over the grate which emits hot flue gases due to combustion.

The grate is provided with equal spacings to ensure complete combustion of the fuel with air.

The hot flue gases from the grate travel through the fire tube and heat transfer take place between the hot gases and the surrounding water.

Then the gases move along the side flues and enter the bottom flue.

Due to the defined flow of flue gases, the water in the shell is heated from the bottom by the bottom flue and the side by the side flue. and also from the center of the fire tube.

When the gases increase the temperature of the walls of the tubes due to which heat transfer takes place between water and tube walls.

This heat transfer increases the temperature of the water so that it starts boiling and converts into vapors.

The gases after passing through the bottom flue finally exit the atmosphere through a chimney.

Advantages of Cornish Boiler:

The following advantages of Cornish Boiler are:

- Due to its simple design and easy construction, it is easy to operate.

- Cornish boilers are portable and small due to which it becomes easy to install it.

- The cost of maintenance is low. A maintenance check is required only once or twice a year.

- The chances of an explosion of the boiler are very less due to low pressure.

Disadvantages of Cornish Boiler:

The following disadvantages of Cornish Boiler are:

- The rate of steam production i.e. 1350 kg/hour is very low, so it can’t be used in large power plants.

- Pressure is low in Cornish boilers so it is less efficient than other boilers.

- If by chance, the boiler bursts it can lead to a lot of damage

- It requires more floor area.

- The circulation of water is not in a definite direction.

Applications of Cornish Boiler:

The following application of Cornish Boiler is:

- It is used in textile, chemical, and paper industries also Used in laboratories and at marine.

- Used to produce steam to run steam turbines.

Internal Resources for You:

- Fire Tube boiler

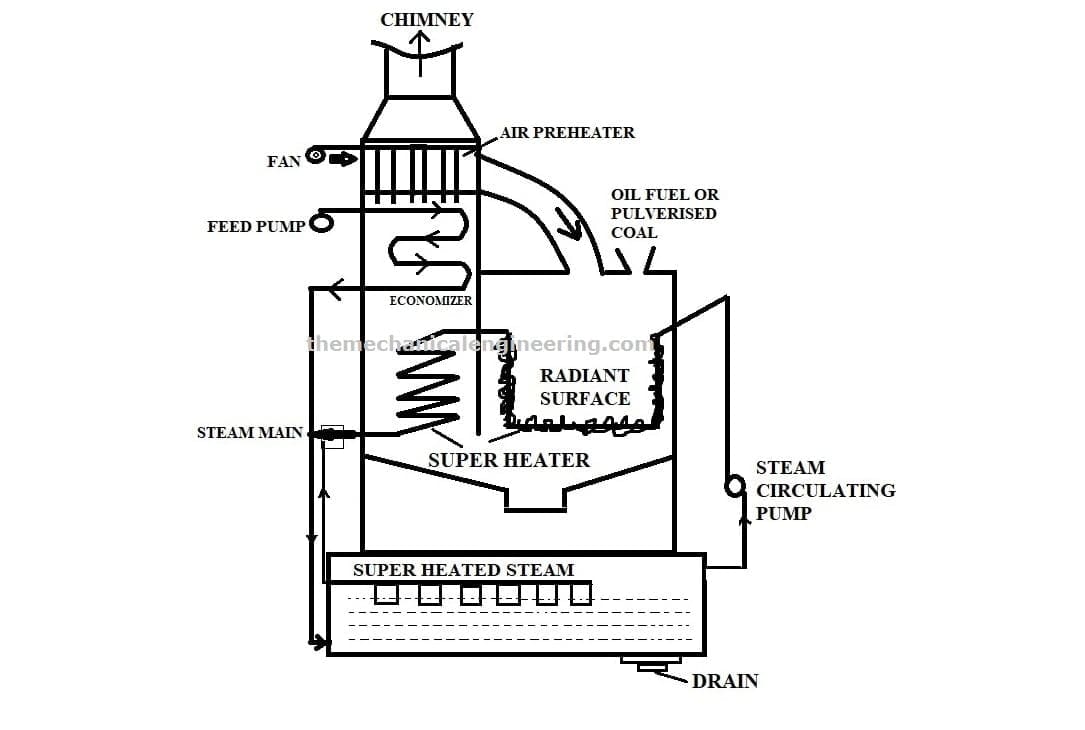

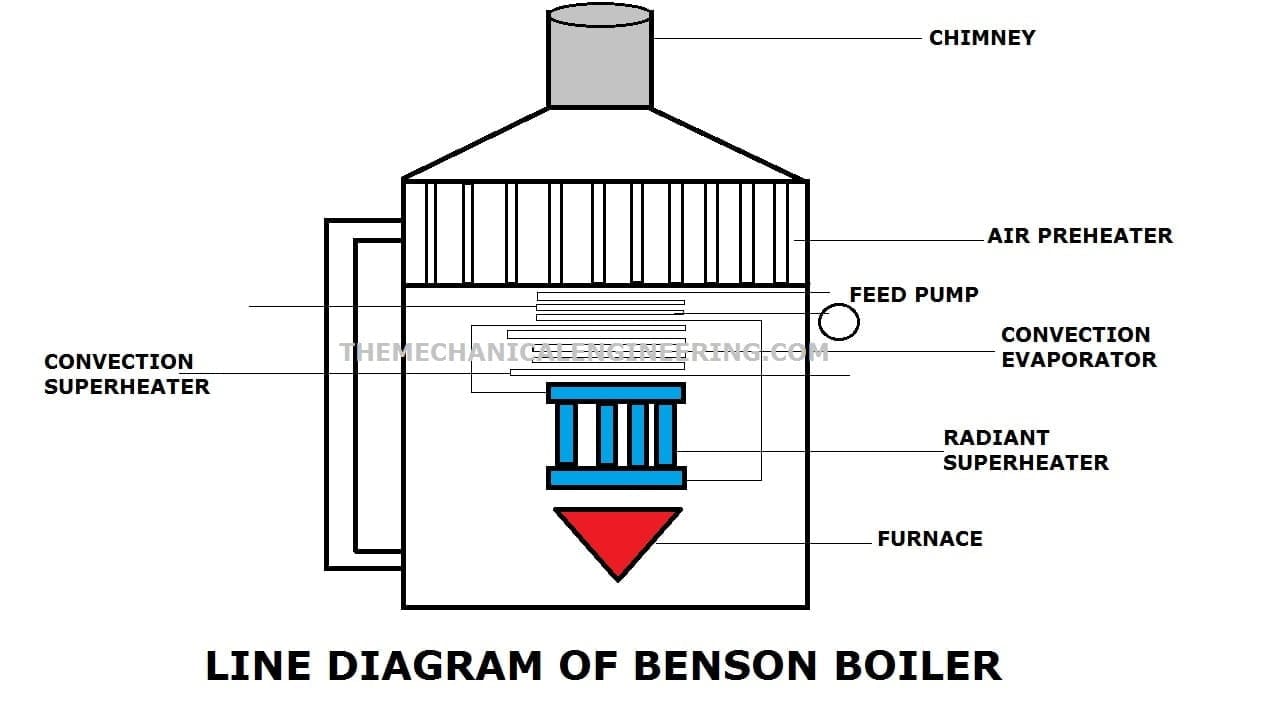

- Benson Boiler

- Locomotive Boiler

- Lamont Boiler

- Cochran Boiler

- Water Tube Boiler

- Difference between Fire Tube and Water Tube Boiler

Reference [External Links]:

Conclusion:

Here we finally studied the Cornish Boiler and its sub-topic Definitions, Parts, Working principles, Advantages, Disadvantages, Applications in detail. I have also written many articles on boiler and types if you are interested then please do check out and Share it with your friends.

And let me know your doubt bout this topic in the comment section. And If there are any improvements needed do let me know or any further recommendations in the comment section.

Discussion about this post