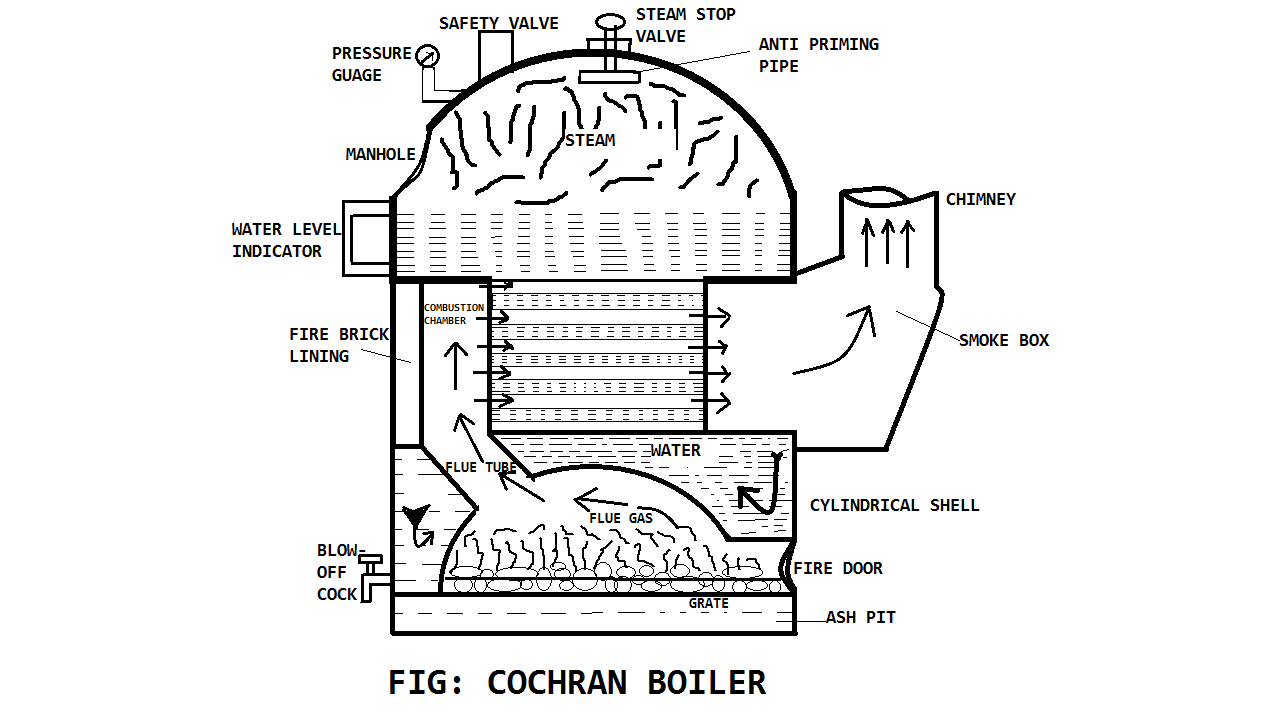

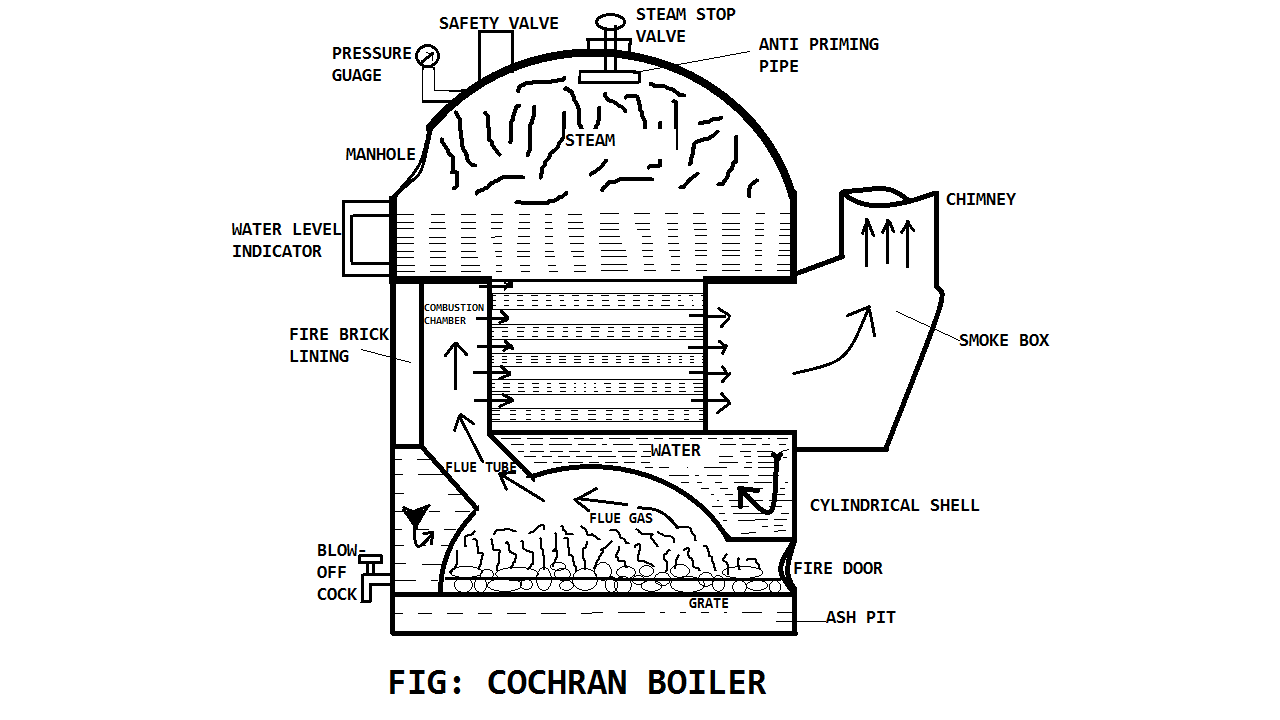

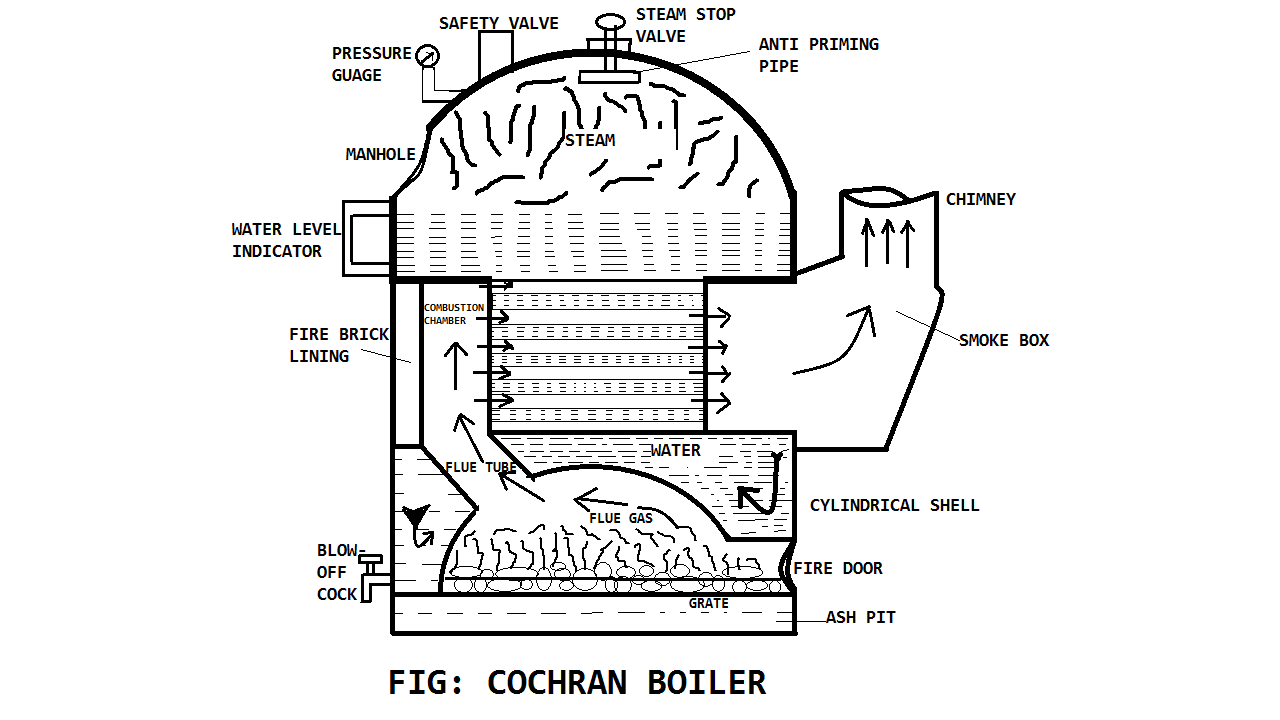

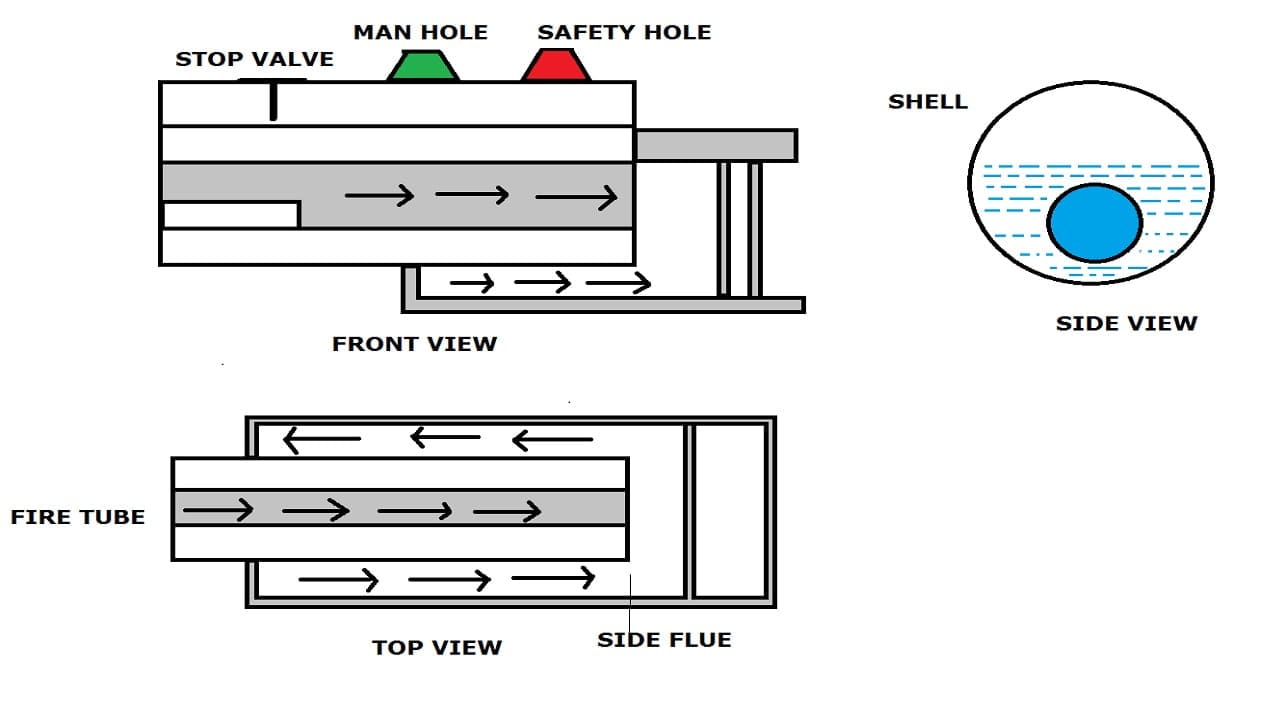

Cochran Boiler is a simple fire tube boiler with multiple fire tubes. It is a modification of a simple vertical boiler.

In the Cochran boiler, the heating surface is replaced with multiple fire tubes that’s why it is the modification of Simple Vertical Boiler. Cochran boiler has greater efficiency comparatively Simple vertical boiler.

Here in this article, we are going to study Definition, Parts or Construction, Working Principle, Advantages, Disadvantages, and Application in very detail.

Note: At the end of every article, you can download PDF.

let’s start with the definition first,

Cochran Boiler Definition:

Cochran boiler is a fire tube boiler (Fire inside the boiler and water surrounding them) in which coal or gases as a working fluid is used, for generating the steam, and that steam is further used for several purposes.

Now comes to the construction,

Cochran Boiler Parts or Construction:

Let’s study one by one,

#1. Grate:

The grate is basically known as the door for placing the fuel. It is made of iron bars and the iron bars are divided into a segment and each segment has two to three bars.

There is adequate space available here for airflow. This airflow helps in the burning of fuel inside the combustion chamber.

#2. Fire door:

The fire is provided through the fire door to start burning fuel inside the boiler.

#3. Ash Pit:

Here, ashes are accumulated under the fire. The ashpit is located below the grate.

#4. Flue Gases:

When the burning of fuel starts in the combustion chamber, it produces a gas that has a certain amount of temperature and this temperature is increasing because of more fuel burning in the combustion chamber already.

The flue gases reach that temperature, where the water surrounds them, starts getting heat and further continuously supply of heat the water gets superheated. The gas is called flue gases.

#5. Flue Pipes:

The main function of the flue pipe is to transmit the hot flue gases from the grate to the combustion chamber. It is connected from the grate to the combustion chamber.

#6. Combustion Chamber:

The combustion chamber is lined with fire bricks on the side of the shell to prevent overheating. The fuel coal which is in the solid form is introduced to burn and produce heat. The combustion chamber has a large area and here the burning of fuel takes place.

The heat produced here has a certain amount of temperature and sends to the fire tube therefore with this amount of temperature the water surrounds gets heated.

#7. Smoke Box:

The smokebox is basically used for storing and releasing the smoke to the chimney during the working process of the Cochran boiler.

It is made of riveted or welded steel plate and the floor is lined with concrete for the protection of the steel from rainwater, hot char, or acid attacks.

#8. Chimney:

The chimney location is at the top of the boiler. It is connected to the smokebox. When the gas gets completely burns and remains only smoke, then this smoke is sent to the smokebox and further, it is sent to the chimney. And from the chimney, the smoke is released into the atmosphere.

#9. Water level Indicator:

It is the most important component of the Cochran boiler. The water level indicator is a measuring instrument and It measures the level of water and gives the detail of the water level in the boiler.

There are few marks available on the instrument for the indication of water level. If it does not function on time then there may be seen damage in the boiler.

#10. Man Hole:

It is also a very important part of the boiler. When things in the boiler get damaged and not working, then a boiler specialist enters through the Man Hole and fixes the damaged parts.

We can say it is for fixing the boiler or its part when it is not working properly.

#11. Pressure gauge:

The pressure gauge is installed at the front of the boiler as you can see in the diagram. We use this instrument in several places. The work of this instrument is to measure the pressure of the steam of the boiler.

In the boiler when pressure is low or the pressure is high, the pressure gauge indicates the pressure of the system, and therefore according to need we control the system.

#12. Safety Valve:

It is to prevent an increase in steam pressure. When the pressure increases above design pressure, the valve opens and discharges the steam to the atmosphere and, When this pressure falls just below the design pressure, the valve closes automatically. Usually, the valve is spring-controlled.

#13. Steam stop valve:

The steam stop valve regulates the supply of steam outside. First, from the boiler, the steam generated comes to an anti priming pipe here some parts of water particles will be removed and it completely remains dry steam then further this steam is used for needed place.

#14. Anti Primimg Pipe:

Anti priming pipe is provided in the boiler for extracting steam from the boiler is only dry saturated steam.

#15. A blow of valve:

Water contains some impurities like mud, sand, and salt. Due to the heating of water, these impurities are deposited to the ground creating a problem and it has to be removed.

So the Blow-off-valve is used for removing these things.

After studying construction now let’s have an overview of how it works,

Cochran Boiler Working Principle:

Working of the Cochran boiler is from the grate the fuel gases or coal are used and that is inserted.

From the firing door, the fire is provided to start the burning of fuel.

The burning of fuel generates hot flue gases and it comes to the combustion chamber. Here almost the temperature is maximum.

We know this is a fire tube boiler. In the tube, hot flue gases pass and water is surrounded.

So the hot flue gases are passing through tubes. The hotness of the fire tube starts heating the surrounded water. The water starts evaporating and at some point it becomes steam.

Now the steam comes at the top of the boiler.

With the use of an Anti priming pipe, the complete steam is extracted from the boiler and here the steam stop valve is placed which works is to transfer the steam to other laces such as the turbine and so on.

When the fuel is burned completely and it becomes ash it comes down to the ash pit and the smoke is released to the chimney and to the atmosphere.

Cochran Boiler Working Video:

It has some advantages and disadvantages too:

Cochran Boiler Advantages:

The following advantages of Cochran Boiler are:

- Coal or Oil type of fuel can be used.

- It is a quick and easy installation.

- Installation and Initial cost of Cochran boiler is a low comparatively another boiler.

- It is a portable(Easily move) type boiler.

- The minimum floor required.

- It has a high volume to area ratio.

Cochran Boiler Disadvantages:

The following disadvantages of Cochran Boiler are:

- Steam generation is low due to vertical design and it is major disadvantages.

- The pressure range is also limited.

- Maintenance is difficult.

Cochran Boiler Application:

The main application of Cochran Boiler is:

- Cochran Boiler used in small power plants and some industries too.

- Refining units.

- Paper manufacturing plants.

- Chemical processing divisions.

Cochran Boiler Specification:

The following Specification of Cochran Boiler are:

- Efficiency is 75 percent.

- Heating Surface area 120 sq meter.

- Working pressure 7 bar and a maximum up to 15 bar.

- Height and Shell diameter is 5.75 and 2.75 meter.

Also, you can read related articles:

References [External Links]:

So here we finally studied all the Cochran Boiler in detail. I hope you have understood this topic. If yes then please share it with your friends and family. Do let me know what further topic I can help you with. Till then Thank you so much for visiting. Bye.

Discussion about this post