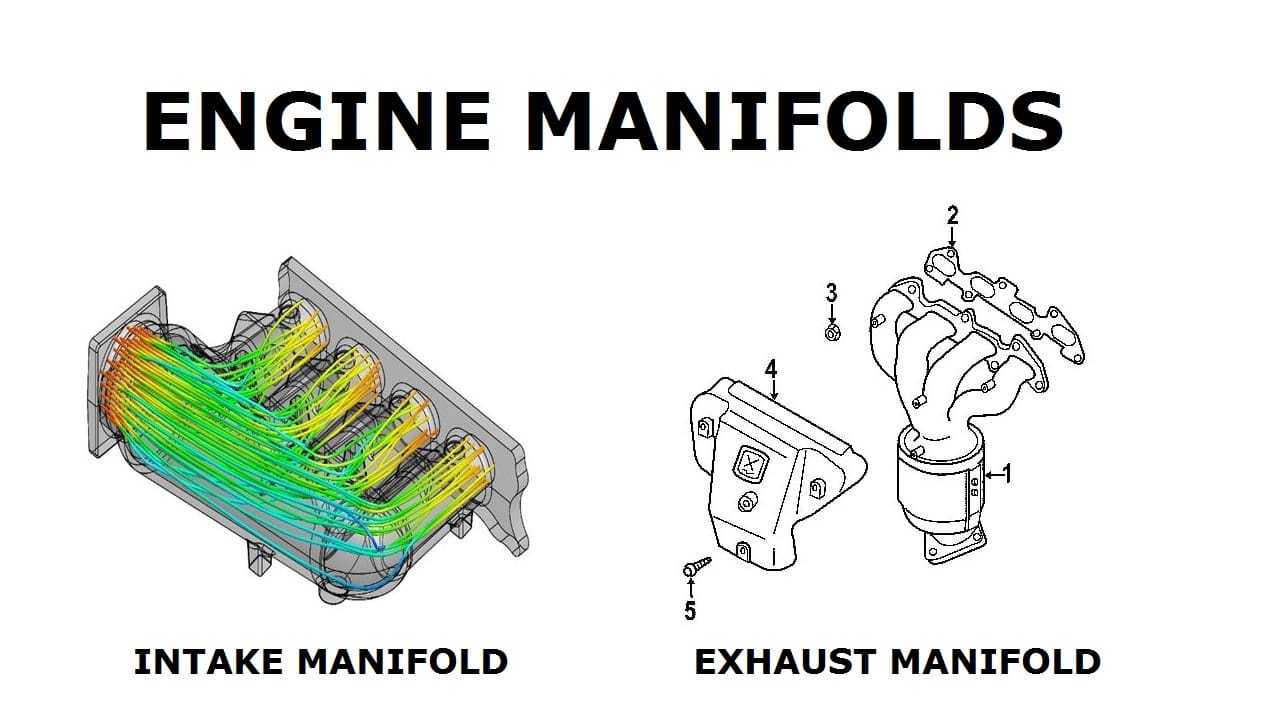

What is an Engine Manifolds?

Engine manifold is a complex tubular structure that is used for the exchange of input and exhaust fluids from an IC engine. Engine manifolds generally have one opening on one side and more than one opening on the other side, this means that the single tube branches into several branched tubes.

The input fluid gets disturbed evenly among the branched tubes which results in the common amount of flow from each output tube.

Engine manifolds are attached to the input and exhaust valves of an IC engine for the routing of fluid inside and outside the engine respectively.

Types of Engine Manifolds:

As discussed earlier the engine manifold transports fluid in and out of the engine. For these purposes, there are two types of engine manifold.

- Intake manifold and

- Exhaust manifold

#1. Intake manifold:

An intake manifold is a complex structure of pipes with one input end and several output ends. The intake manifold is also known as the inlet manifold.

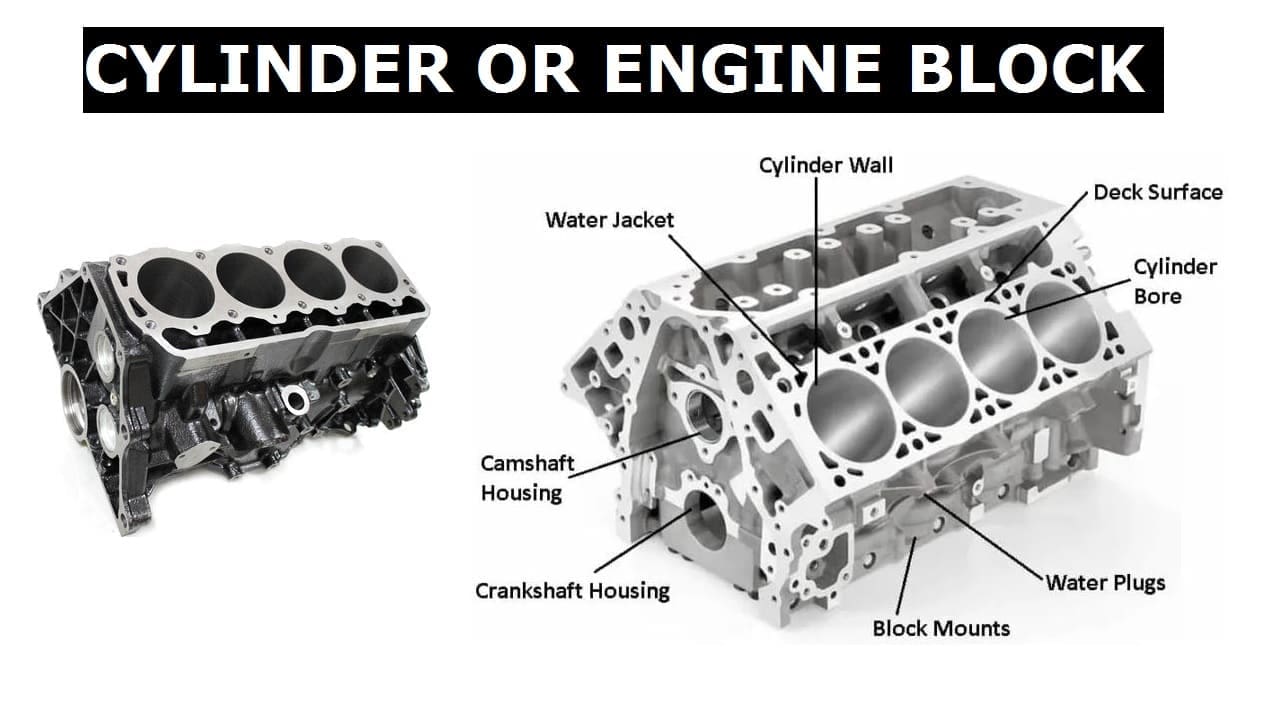

As the name suggests an intake manifold is used to deliver the fluid into the cylinder block via an inlet valve. The fluid entering the diesel engine is air and the fluid entering the petrol engine is the mixture of air and fuel.

Construction of an intake manifold:

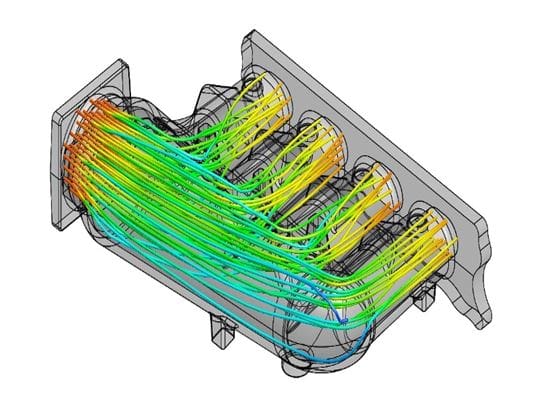

The figure below shows the basic construction of an intake manifold.

In the figure, one can observe that there is a single input tube and 4 output tubes. This means that the intake manifold is used for a 4 cylinder engine.

Each of the four output tubes is connected to the inlet valves. This provides an even transfer or charge or air in every cylinder.

The charge enters from a carburetor in the case of a petrol engine and in the case of a diesel engine only air enters through an air filter.

The design of intake manifolds is done such that there should not be an uneven distribution of charge or air in each cylinder.

In the case of a petrol engine, the intake manifold must have a higher temperature so that the air-fuel mixture does not get condensed. For this reason, the temperature of the intake manifold is kept high using hot exhaust gases.

This is very much needed in cold areas or regions. The modern-day intake manifold consists of an ECU sensor that senses the input pressure, the flow of the charge, etc.

Working of the intake manifold:

When the engine starts it requires charge in the case of petrol engines and air in the case of diesel engines.

The charge/air must be distributed evenly among each cylinder of a multi-cylinder engine.

The air/charge via an air filter enters the single opening of the intake manifold and then gets evenly distributed among the branched tubes.

Then the air/charge from the branched tubes enters the cylinder block through the intake valve.

Important points about an inlet manifold:

- Inlet manifolds must be designed accurately.

- It must be checked for any leakage before installation.

- A gasket should be used between the engine block and output tube to prevent leakage.

- If the charge or air is not distributed evenly between all the cylinders the power in each cylinder will be different and this can cause rough running of the engine.

Materials used to make the intake manifold:

Traditional intake manifolds are made of either cast iron or aluminum. But in some modern-day engines, the intake manifolds are made of thermoplastic materials. Nylon 6/6 is the material that is generally used for making intake manifolds for multi-cylinder engines.

The use of plastic intake manifolds has increased in recent years in Europe. About 50% of the total plastic intake manifolds can be seen in automobiles in Europe. The main reason for using plastic intake manifolds is that they are lightweight and inexpensive.

Advantages of the intake manifold:

- Low cost.

- Simple mechanism.

- Even distribution of charge.

- Can be controlled using the software.

Disadvantages of the intake manifold:

- Complex design.

- Vacuum is generated.

- Leakages are difficult to find out.

- Corrosion is also an issue.

#2. Exhaust manifold:

The exhaust manifold is a complex structure of tubes with several input openings and one output opening. These are used to remove the exhaust gases out from the engine via exhaust/outlet valves. It allows the burnt gases containing carbon and other chemical toxins to vent out from the engine to the silencer of the vehicle.

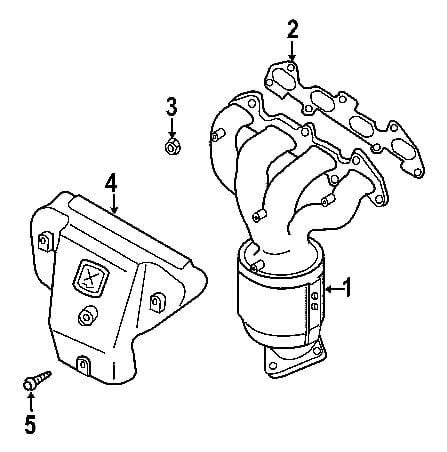

Construction of an exhaust manifold:

The basic diagram of an exhaust manifold is given below. The diagram shows an exhaust manifold with three input pipes and one output pipe this means that the exhaust manifold shown in the figure is for a 3 cylinder engine.

The exhaust manifold provides a clean transfer of exhaust gases out of the cylinder block. They are designed in such a way that the back force generated by the exhaust gases is minimized. The exhaust manifold is connected to the engine block with the help of a gasket so that there should not be any leakage.

When the exhaust valve opens the exhaust gases from the cylinder reach the input opening of the exhaust manifold. Gases from each cylinder are received by the exhaust manifold and then it is pushed out from the single output passage.

There is an oxygen sensor fitted inside the exhaust manifold to detect the amount of oxygen present in the exhaust gases.

An important part of the exhaust manifold of the petrol engine is the heart valve. The heat directs the hot exhaust gases to the intake manifold to heat the air-fuel mixture so that it does not get condensed.

Working of an Exhaust manifold:

The exhaust gases leaving from each cylinder of a multi-cylinder engine require proper emission without generation of back-pressure.

The input openings of the exhaust manifold are connected to each of the cylinder blocks.

The exhaust gases are collected by each opening and then are released through a single output tube which is connected to the silencer of the vehicle.

Important points about the exhaust manifold:

- The design of the exhaust manifold must ensure proper scavenging of the exhaust gases.

- There should not be a generation of backpressure.

- If there is a leak in the exhaust manifold, a noise is generated which is known as puffing noise.

- Sometimes the puffing noise is heard at the time of starting and it vanishes when the engine temperature rises. In this case, the exhaust manifold must be checked.

Materials used for making exhaust manifold:

The exhaust manifold is generally made of cast iron. The reason behind this is the high working temperature. Though aluminum is a metal and is used for making intake manifolds it heats up very rapidly hence is not a preferable choice for exhaust manifolds.

On the other hand, one cannot think of using any kind of plastic to operate at such high temperatures. Hence cast iron being cheap and easy to handle as well as providing fair resistance against heat is the suitable material for making exhaust manifolds.

Advantages of the exhaust manifold:

- The exhaust manifold prevents the engine from overheating.

- It uses exhaust gases to heat the intake manifold.

- Prevents the exhaust gases from coming back into the cylinder.

Disadvantages of the exhaust manifold:

- Leakage is a common problem with the exhaust manifold.

- Due to excess heat Corrosion may occur.

- Results in the noisy operation of the engine.

Internal Resources:

- Flywheel

- Camshaft

- Propeller Shaft

- Clutch complete Notes

- Electronic Ignition System

- Battery Ignition System

- Lubrication System Types

- Braking System Types

- Magneto Ignition System

- Single Plate Clutch

- Multi-Plate Clutch

Reference [External Links]:

- https://en.wikipedia.org/wiki/Inlet_manifold

- https://en.wikipedia.org/wiki/Exhaust_manifold

- Youtube Video: Intake Manifold

Conclusion:

So here we have studied Engine Manifold in detail. Let me know what else I can help you in this topic or any other topic?.

Discussion about this post