In this Planer Machine article, we will study Definition, Parts, Working, Types, Operation, Advantages, Disadvantages, and Application.

Note: At the end of the article you can download PDF of Planer Machine.

So now lets start with the Introduction first,

Planer Machine Introduction:

The principle of the planner machine is the concept of relative tool-work motions. Reciprocation of the tool or job and the slow, intermittent transverse feed motions are imparted to the job or tool by the fast straight path cutting motion.

Al the operations done in planning machines can be done in the shaping machine. Stroke length, larger size, and higher rigidity enable the planning machines to do more heavy-duty work on large jobs and their long surfaces.

It produces planes and flat surfaces with a single-point cutting tool. A planer machine is large and massive as compared to a shaper machine. The planer can do machining heavy workpiece, which cannot be done on a shaper surface.

Planer Machine Definition:

Planer Machine is a machine in which unwanted material is cut from the workpiece to produce a flat surface on the workpiece. Unlike Shaper Machine, in this machine, more than one tool can be set and perform an operation.

Now let’s see the construction or Parts of Planer Machine,

Planer Machine Parts:

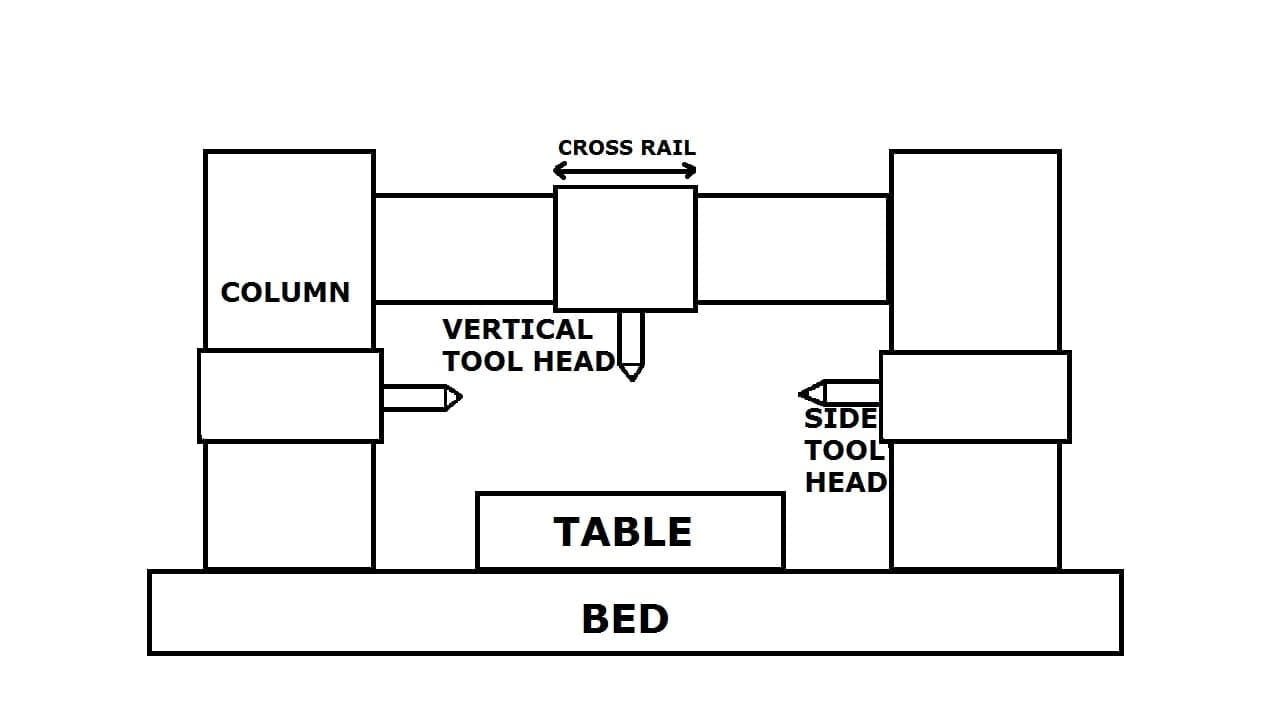

The following Construction or Main Parts of Planer Machine are:

- Bed

- Column or Housing

- Table

- Cross Rail

- Tool Head

- Driving

- Feed Mechanism

Bed:

The bed of a planer having cross ribs similar to box-like casting. It is heavy in weight and very large in size also it supports the column and moving parts of the machine.

The bed is made generally longer than the length of the table, almost twice the length. So that the full length of the table may across it. To support the table guideways may be provided on a very large machine.

The guideways should be horizontal and parallel to each other. The guideways are lubricated properly and to ensure a continuous and adequate supply of lubricants in modern machines, oil under pressure is pumped into the different parts of the guideways.

Column or Housing:

The housings also called columns like vertical structures placed on each side of the bed and are attached to the sides of the bed. They are heavily mechanized to continue severe forces due to cutting.

Cross rail may be made to slide up and down for accommodating different heights of work to the front face of each housing is accurately machined to provide precision ways.

Two side-tool head also slide upon it. Planer housing encloses the Crossrail elevating screw, vertical and crossfeed screws for tool heads, counterbalancing weight for the Crossrail.

The planer screws can be operated by hand or power.

Table:

The table of the planer supports the workpiece and reciprocates along with the ways of the bed. The planer table is a heavy rectangular casting that has T-slots provided on the entire length of the table so that the work and work holding devices attached to it.

In the end, a hollow space is left which acts as a carrier for collecting chips. Works can also rest upon the troughs of the planer.

The table is made up of one single casting but it is divided by the table of planer there are two separate tables mounted upon the bed ways.

Hydraulic bumpers are attached to the end of the bed to stop the table from overrunning that will give the cushioning effect. If the table overruns, a large cutting tool bolted along the underside of the table which will take a deep cut on a replaceable block absorbing the kinetic energy of the moving table.

Cross Rail:

The Crossrail is a casting that connects the two housings. Crossrail provides rigidity to the machine. It occupies the face of the housing and can be clamped at the position by manual, hydraulic devices.

The Crossrail when clamped should remain absolutely parallel to the top surface of the table, i.e. It must be horizontal irrespective of its position.

Two tool heads are mounted which are called railhead. It has screws for vertical and crossfeed of the tool heads and a screw for elevating the rail. The planer screws can be operated by hand or power.

Tool Head:

Tool head is a component assembled to saddle, which has the tool post in it. The tool post is attached to the head so that on to and from of the table the cutting tool force is raised.

The cutting edge of the tool will be saved as of being damage and permits the automatic supply to function with no intrusion.

It has Saddle, Swivel base, Vertical Slide, Apron, Clapper box, Clapper block, Toolpost, Down feed screw, Apron, clamping bolt, Apron swiveling pin, Mechanism for cross and down-feed of the tool.

Driving and Feed Mechanism:

The feeding mechanism of the tool head is by the hand of power in a crosswise or in a vertical direction. The drive mechanism is located under the table and The motor drive is at one side of the planer.

The size of the planer is specified by the maximum length of the stroke and it is also specified by the largest rectangular size that can be machined.

Now we study working of Planer Machine,

Planer Machine Working Principle:

The worktable can be move and the tool head of the machine is in a stationary position. The workpiece is fixed on the work table and

The single point cutting tool is attached to the tool head and now we switch on the machine that means power supply to the machine and the worktable moves forward.

Hence it cuts the material and it is called cutting stroke. The worktable moves downward there is no cutting of material so this is called the return stroke. The process will be continued unless you change the power supply or others.

Planer Machine Working Video:

Planer Machine Mechanism:

Kinematics and its mechanism involve transformation and transmission of rotation of the motor into reciprocating motion of the work table and the transverse motions of the tools.

The reciprocation motion of the table that gives cutting motion to the job, is obtained by a rack-pinion mechanism. The rack is fitted with the table and the pinion is fitted on the output shaft of the speed gearbox.

The blocks hold the cutting tools that move horizontally along the rail by the screw-nut system and the rail is again moved up and down by screw-nut pair different from it.

The belts are used as drivers to reciprocate the table alternatively. The greater arc of contact on the larger pulley is used to drive the table.

Greater power and less speed is required during the cutting stroke and is done by connecting the cross belt with a larger diameter pulley which is fed on the shaft.

The power from the shaft transmits through pinion P and spur gear.

Now moving to types,

Planer Machine Types:

Planer Machine have five different Types:

- Double Housing Planer Machine

- Pit Planer Machine

- Open Side Machine

- Edge Planer Machine and

- Divided Table Planer Machine

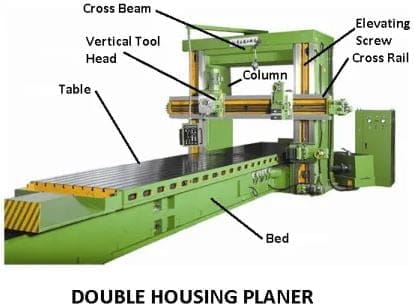

Double Housing Planer Machine:

Most of the workshops use a double housing planer machine. Double housing planers have a long heavy base with machined guideways accurate on which a table reciprocates. The bed length is greater than twice the length of the table.

Two vertical housings are mounted one housing: One on each side and these are connected at the top by a cross member. It has a horizontal cross rail that carries two tool heads slides over the vertical faces of the machine housing.

Tool heads are moved by hand or power in the cross or vertical direction for the feeding operation. Double housing planer is a high speed, heavy-duty as well as rigid machines.

It has a high degree of surface finish. Work is mounted on a table which reciprocates while the tool is held on the machine frame. It can make deep cuts and heavy feeds can be applied to finish the work in a short time. The tool is stationery and work is moving. Heavier, stronger, and larger tools are used.

Throughout the stroke cutting and return, speeds are uniform. Double housing Planer consumes a power of 150 horsepower and the double housing holds the large floor area.

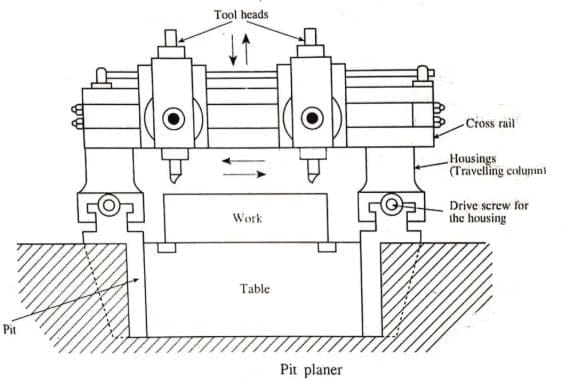

Pit Planer Machine:

Pit planer has a massive construction in which the table is kept in a pit and kept stationary. The crosses rail reciprocates on a horizontal rail mounted on both sides of the table.

The table of the planer is leveled with the floor, so heavy work can be loaded. It has two tool heads and these can be moved horizontally and vertically to have the feed. By means of a motor, a driving screw is used for driving the column.

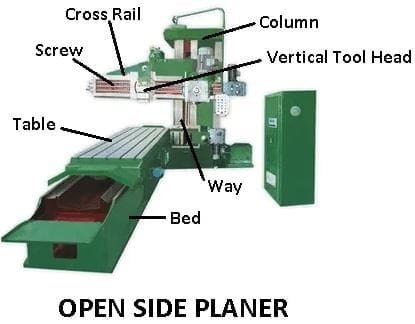

Open Side Planer Machine:

One housing on one side of the base is attached or clamped on which a cross rail on a table moves.

The open side planer machine has three tool heads mounted on the machine. Single housing will bear the entire load, Therefore it should be rigid and robust to face the forces.

It can slide along the guideways of the housing in the vertical direction which carries the tool heads.

Edge Planer Machine:

Edge planer is also called plate planer and is used for bevelling and squaring the edges of steel plates used for pressure vessels in different applications and in the ship buildings industry.

The table holds the work that remains in a stationary position. The workpiece can be attached by air-operated clamps. The tool-head that mounts on the carriage moves along two horizontal guideways.

Divided Table Planer Machine

Divided table Planer Machine has two tables on the bed that can reciprocate separately or jointly. This will saves the idle time when you set the work.

Divided type planer is mostly suitable for mass production work that can Machine is to be done identically, the work on one of the tables is loaded, the other part can reciprocate the cutting tool for the finishing process.

Finishing the work can be done after the table is stopped and the finished job is ejected by shifting the table to the end. Heavy and large jobs are clamped together therefore given the reciprocating movement by the tool.

Now we will study Advantages, Disadvantages and Application.

Planer Machine Advantages:

The following advantages of Planer Machine as follows:

- It has Greater accuracy,

- Good surface finish,

- More than one tool can perform on the workpiece at a time and

- Low maintenance is required.

Planer Machine Disadvantages:

The following disadvantages of Planer Machine as follows:

- The cost of the machine is on the higher side.

- The power consumption is quite more.

- The skilled worker required.

- Only tool single point is used.

Planer Machine Application:

The following application of Planer Machine as follows:

- The Planer machine is used for Flat surfaces on the workpiece.

- Cutting angular surfaces is one of the major applications.

- Cutting slots and grooves.

Related Article:

Milling Machine

Drilling Machine

Shaper Machine

Slotter Machine

So here we have studied Planer Machine in detail. Let me know what else I can help you with this. Till then if this article found helpful then don’t forget to share it on social platforms.

Discussion about this post