In this article, we are going to study Scotch Marine Boiler and Its sub-topics like Definition, Parts, Working Principle, Types, Advantages, Disadvantages, Application in detail.

And at the end, you can download the PDF version easily.

So let’s start our topic with a Definition first,

Scotch Marine Boiler Definition:

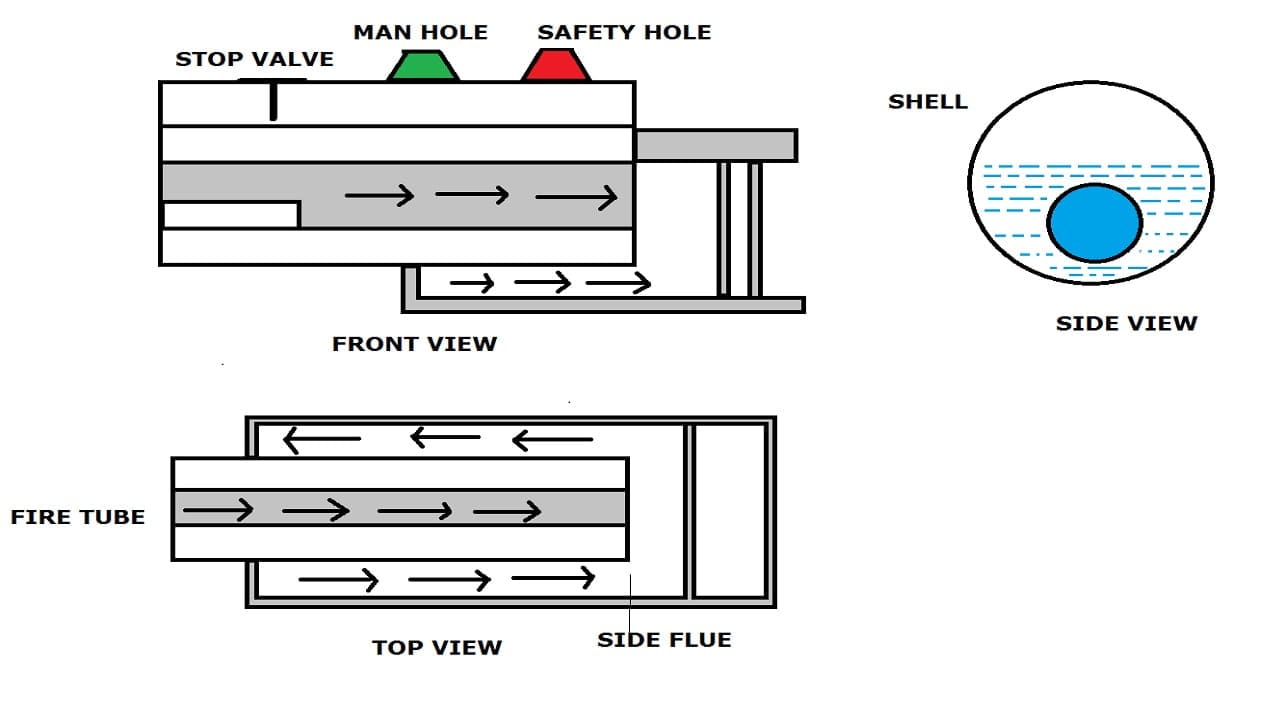

Scotch Marine Boiler is also known as a fire tube boiler. It is one of the most common boilers, which are generally used in the marine sections on ships. This boiler is used for the ability of compactness and efficiency in operations.

The general outline of the fire-tube boiler is that it consists of two or more horizontal cylinder furnaces, located at the base of the boiler shell. The burst gases and smoke pass from the furnace to the back of the boiler and return to its small tubes and get worn out of the chimney.

Construction or Parts of Scotch Marine Boiler:

The following Main Parts or Construction of the Scotch Marine boiler:

- Furnace

- Combustion chamber

- Smokebox

- Chimney

- Boiler shell

- Soot boiler

- Main-hole

- Safety tube and

- Boiler-tube

Furnace:

The furnace is placed above the grate at the base of the boiler; the solid fuel inside the boiler is burnt down by the use of this furnace.

It is a single-ended boiler that consists of four furnaces. These furnaces are normally channelized for strength. In this type of boiler, each furnace has its separate combustion chamber.

Combustion Chamber:

The Combustion Chamber is located at the base of the boiler shield, used to produce steam by burning fuel from the water retained at the shell. The chamber consists of fine plates, top plate, backplate, two sides’ plate, and tube plate.

Smoke Box:

The smoke-box consists of several smoke tubes which are placed horizontally, connected with the combustion chamber of the chimney. The smoke moves to the smoke tubes and lastly enters the chimney.

Chimney:

The chimney is placed to wear out the unwanted gases and smoke out of the boiler, and it is released into the atmosphere.

Soot Blower:

Its general design is to remove soot, which is deposited at the base of the internal surface of the boiler. The boiler becomes less efficient when the soot is not removed.

Main-Hole:

A manhole is also convened as a manhole, as a man enters (the boiler specialist) when the working parts of the boiler get damaged.

Safety valve:

It gives instructions about the boiler such as pressure, water, heat, and other substance use.

Boiler tube:

The boiler tube has an instrument that is used to produce a whistle when it reaches the limit as per set.

Boiler shell:

A boiler shell is an important part of the boiler. It consists of steel and produces much strength to protect the internal parts of the boiler.

Now we will see how does it work?

Scotch Marine Boiler Working Principle:

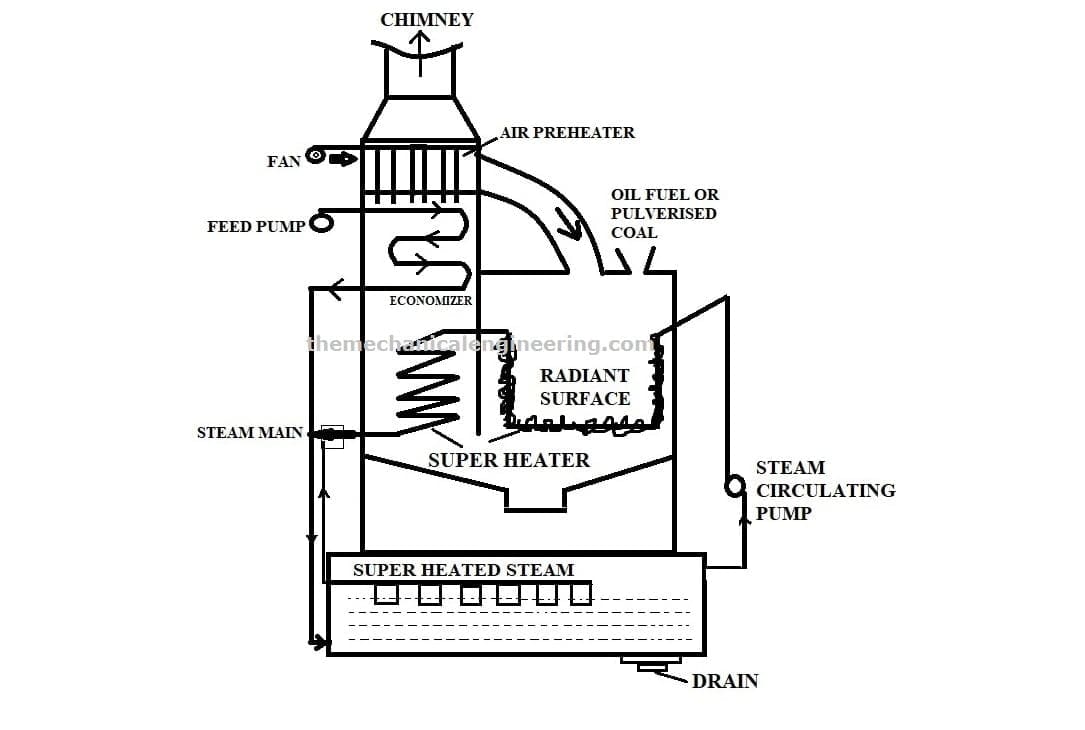

The fuel gets filled into the furnace through the medium of a fire- hole and heat is ignited.

The fuel gets burnt on the furnace and results in generating the burnt gases. This heated gas moves to the combustion chamber, as a result of producing a large amount of heat into the combustion chamber, used to heat the surrounded water.

The water gets transformed into steam and passes to the steam turbine.

The water encircles the furnace, combustion chamber, and smoke tubes resulting in providing a greater heating surface for the water.

The exhaust burnt gas moves to the chimney through smoke tubes.

The chimney helps in discharging the gases into the environment.

In this boiler, the degree of water is retained a little above the combustion chamber.

Scotch Marine Boiler Working Video:

You can watch the video at 1.5x.

Scotch Marine Boiler Design:

Two Basic Design of Scotch Marine Boiler:

- Dryback boiler and

- Wetback boiler

Dryback boiler:

The Dryback boiler contains a rear wall that is lined with refractory, which moves from the combustion gasses, the furnace, to the tube sheets and reflects burner heat, causing an external radiation loss. This design of boiler operates using a rear tube and features convenient fire-slide and water-slide access.

Advantages:

- Minimum maintenance is required with strong construction for extra-life.

- It consists of a large combustion chamber with minimum heat release for complete combustion.

- It is way more durable than others

- Available in both steam and hot water version.

Wetback Boiler:

This boiler shows a reversal chamber that is surrounded by water, uses as a medium to direct flue gasses from the furnace to the tube. The surrounding water captures heat, increasing the operational efficiency as heat from the combustion passes rapidly into the warm heating water instead of refractory. It uses a separate tube sheet, between tubes passes tobe more pardoning with load changes.

Advantages:

- Its Door design lessens the need for floor space requirements.

- No cost of refractory for its maintenance.

- It increases the efficiency of water-absorbing burner heat.

- It could be opened immediately, as it requires less cooling period

- It consists of separate tubesheets, which can be expanded and contracted in response to temperature changes between passes.

- It has a non-proprietary design for cheap and easy installation.

Types of Scotch Marine Boiler?

There are two types of Scotch Marine Boiler:

- Single-handed boiler and

- Double-handed boiler.

Single-handed boiler:

It has a circular boiler shell with a large diameter and a short length. Its length varies up to 3.5 meters. It consists of four furnaces. It is the most traditional type of boiler, which is used in steamship for many countries.

Double-handed boiler:

The double-handed scotch marine boiler has a vertical Galloway tube made into the combustion chamber. It circulates the water in the boiler and has a length of up to 6.5 meters. In this boiler, the furnaces are present at the end of it. The number of furnaces changes from 2 to 4 at each end.

Advantages of Scotch Marine Boiler:

The following advantages of Scotch Marine Boiler:

- The Boiler is made with a lot of heating surface, normally five Square feet of heat transfer surface per boiler HP. This produces higher resistance and efficiency to fouling.

- As this boiler has a large diameter shell that contains water and steam and also a steam chest, the disengaging area produces good quality steam without the addition of mechanical separation.

- The furnace can be manufactured large enough to support different fuels and emission requirements.

- It produces a higher level of energy, which allows it to generate a higher steam flow rate with a minimum amount of pressure.

- Its large-sized shell allows more flexibility in water treatment and blowdown maintenance.

Disadvantages of Scotch Marine Boiler:

The following disadvantages of Scotch Marine Boiler:

- It requires more loads of area for a based output.

- The variations in loads cannot be easily controlled.

- Mostly used in small power plants.

- The steam rate formation and quality are not much than the water tube boilers for suitable power generation.

- Because of the large diameter, the steam pressure is limited to around 300 PSI.

- It runs with a longer warmup cycle, frequently requires backup boilers to be kept for faster response, this makes it more expensive and complicates the process.

Application of the Scotch Marine Boiler:

The following two main applications of Scotch Marine Boiler:

- This boiler is commonly used in marine sections, for its compactness, efficiency, and favorableto operate in any type of water

- The Boiler is mainly used in ships.

Internal Resources:

- Water-tube boiler

- Fire Tube boiler

- Cornish Boiler

- Lamont Boiler

- Babcock and Wilcox Boiler

- Lancashire Boiler

- Cochran Boiler

- Benson Boiler

Conclusion:

Here we studied Scotch Marine Boiler in detail. Let me know what further I can help you with. Till then if this article helps you please share it with your friends and family. Thank you for reading.

Discussion about this post