Loeffler Boiler is a high-pressure boiler. In this article, we will study Definitions, Parts, Working principles, Types, Advantages, Disadvantages, and Applications of the Loeffler Boiler in detail.

Before moving to our main topic Loeffler boiler. Let’s have an overview of High-pressure boiler first,

High-pressure boilers are boilers that operate under High-Pressures. But why are High-Pressure boilers used?

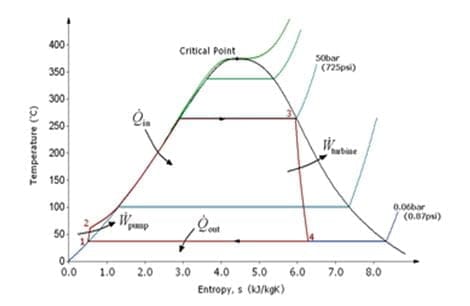

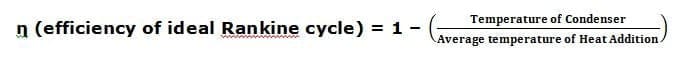

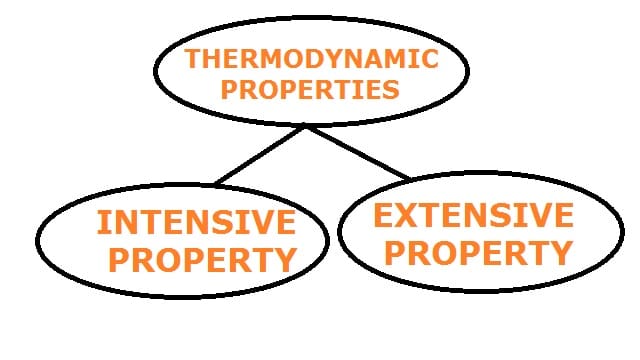

In this above diagram, Process 2-3 is the heat-addition process of the Rankine cycle, which is a constant pressure process, where the boiler operates. The efficiency of the Rankine cycle depends upon the average temperature of heat addition from points 2 to 3, efficiency being directly proportional to the average temperature of heat addition which itself is directly proportional to the pressure at which heat addition is taking place in the boiler.

- Therefore, High-Pressure boilers are used for increased efficiency of the cycle.

- Low-pressure boilers operate at less than 20 bar pressure. Ex. Lancashire Boiler, Cochran Boiler

- Medium-pressure boilers operate at pressure more than 20 bar and less than 75 bar.

- High-pressure boilers operate at more than 75 bar pressure. Ex. LaMont Boiler, Benson Boiler, Loeffler Boiler. In High-Pressure Boilers, water circulation is Forced Water Circulation, where water is circulated in a boiler via a pump (centrifugal pumps are employed for this purpose).

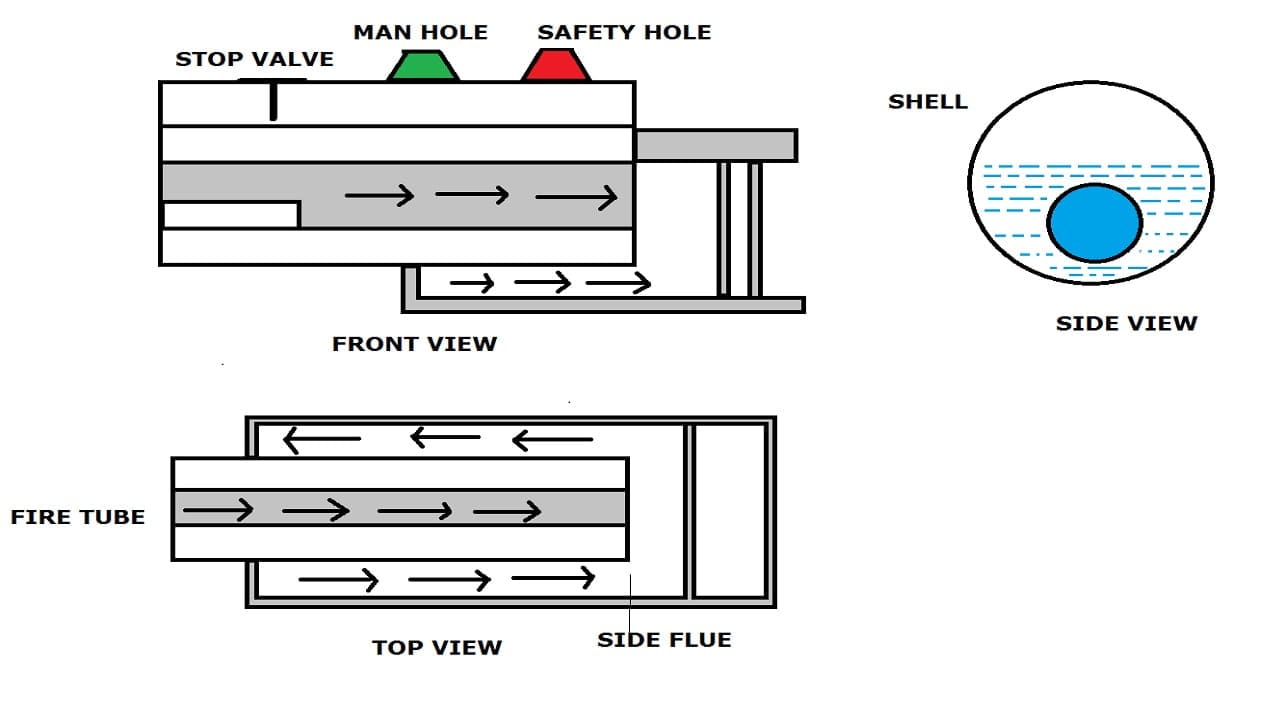

The design of High-Pressure Boilers is robust. These types of boilers are generally water-tube boilers ( water is inside the tubes and hot gases surround them ) because High-Pressure is in the tubes and not in flue gases.

The Benefit of High-Pressure boilers:

- The temperature of the Boiler remains uniform because it operates at High-Pressure and temperature.

- Scale formation is prevented due to the high velocity of water through the tubes because of forced water circulation.

- Freedom of placement of grate due to the forced circulation of water through tubes.

- The efficiency of High-Pressure boilers is high. Therefore, the amount of steam required for the same output is low.

Now coming to our main topic,

What is the Definition of Loeffler Boiler?

Loeffler Boiler is a High-Pressure, forced-circulation, water-tube boiler. Two important features of this boiler are a) the Use of turbines and b) the use of superheated steam to generate steam. The principle behind the working of Loeffler Boiler is “evaporation of feedwater by means of superheated steam from the superheater”. This prevents any soot deposition (will be discussed later).

Since Loeffler boilers are used for marine applications and sooting is prevented, saline water can also be used. Also, we are getting output from two turbines, Loeffler boilers are compact boilers. The Loeffler Boiler has a generating capacity of 100 tonnes/h of steam, operating at 140 bar and 500°C.

Construction or Parts of Loeffler Boiler:

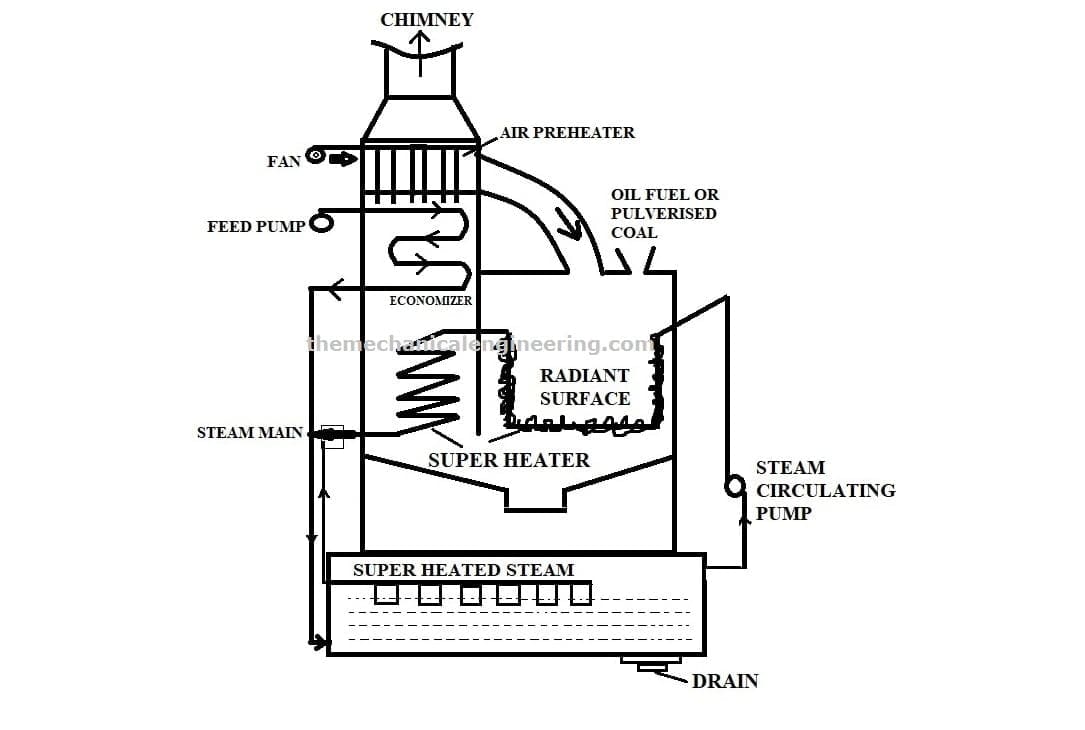

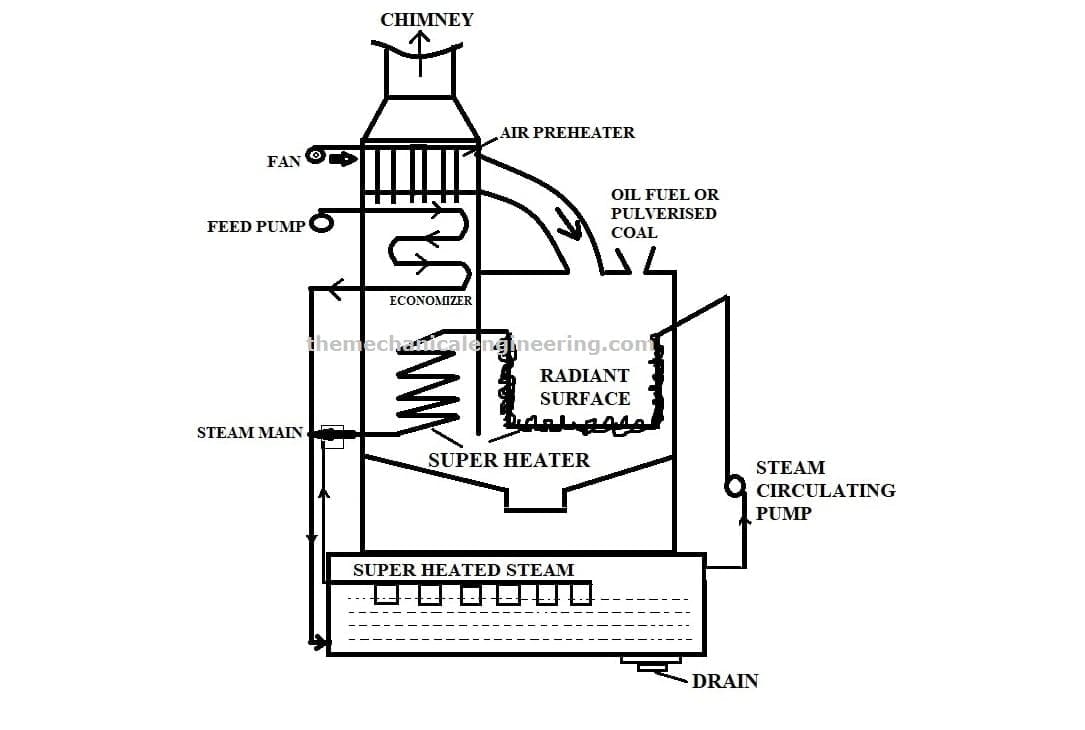

Loeffler Boiler consists of the following Parts:

- Feed Pump

- Economizer

- Air Preheater

- Evaporating Drum

- Mixing Nozzle

- Steam Circulating Pump

- Superheaters

- Radiant Superheater

- Convective Superheater

- Turbine

- Steam Main

- Fan

- Chimney

Feed Pump:

The feed pump is made of high strength, corrosion, and erosion-resistant martensitic chrome steels (chrome content of 13-14%). And It serves to feed the boiler with a quantity of feedwater corresponding to the quantity of steam required.

Economizer:

An economizer is a device that facilitates the exchange of heat energy between the flue gases and feedwater before the flue gases leave the boiler through the chimney.

In Figure 1, feedwater at point 2 is High-Pressure feedwater. Heating this feedwater increases the net ( average ) temperature of heat addition or decreases the amount of heat required in the boiler.

The economizer consists of vertical cast iron ( steel water pipes ) connected at both ends by horizontal pipes (Top header and bottom header). Heat exchange takes place while feedwater is rising in the vertical pipes.

Soot deposition problem is prevalent in boilers, especially economizers.

Flue gases pass over the vertical tubes for heat exchange. Flue gases consist of burnt carbon particles that stick to the surface of tubes and lead to the problem of soot deposition which hampers the heat transfer capacity of the economizer. Therefore, soot scrapers are provided with a pulley and chain arrangement to scratch the surface of the tubes to remove soot.

However, in the Loeffler boiler, steam is generated by superheated steam and not by flue gases. Therefore the soot deposition problem is eliminated in the evaporating drum.

Air Preheater:

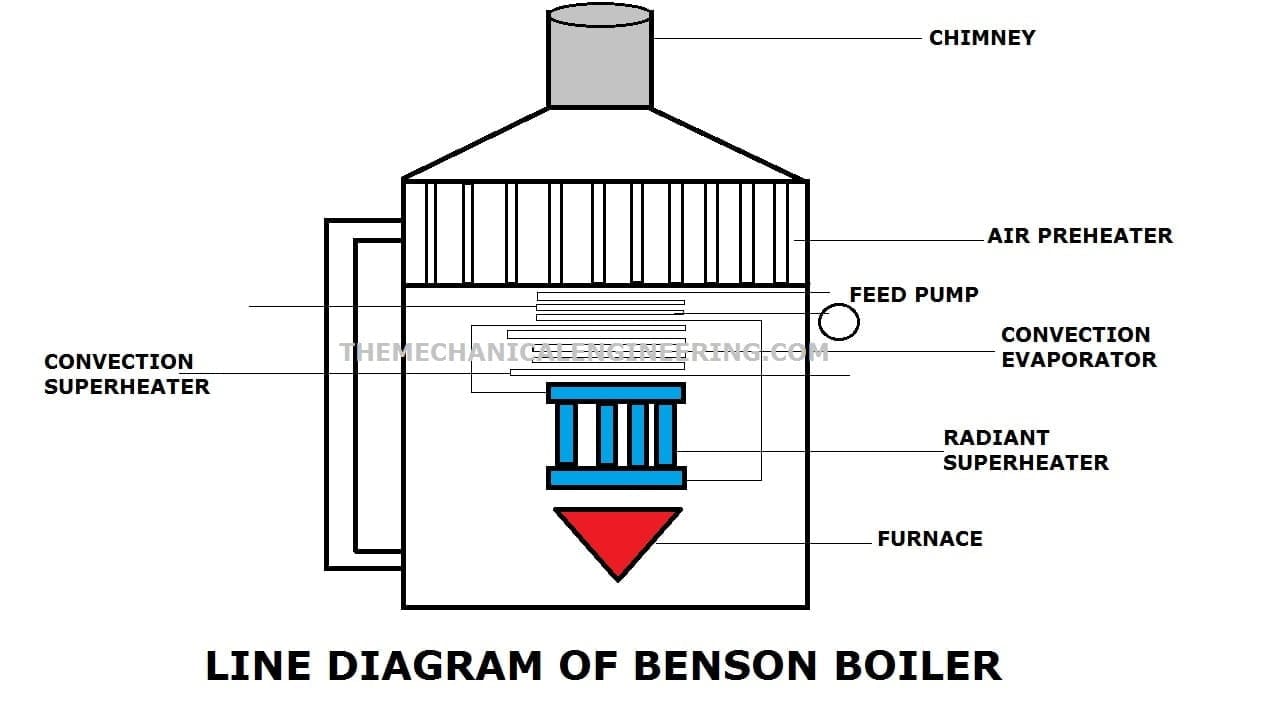

Air Preheater is a device designed to heat air. It increases the efficiency of the boiler by heating the air through the exchange of the energy between flue gases and air before sending the air to the grate for combustion purposes. Air preheaters are installed between the economizer and chimney.

Evaporating Drum:

Evaporating Drum is placed at the bottom of the boiler, and is a reservoir of water/steam.

Mixing Nozzle:

Mixing Nozzle facilitates mixing of feed water and superheated steam for evaporation in the evaporating drum.

Steam Circulating Pump:

A steam Circulating pump is a centrifugal pump, designed to generate forced circulation in the Loeffler boiler, to transmit steam to the boiler.

Super Heaters:

Superheaters are coil-type heat exchangers to convert low-quality steam (high moisture content in steam) to high-quality steam ( low moisture content in steam ).

Radiant Super heater:

Radiant Superheater (Placed in the radiant zone of the combustion chamber, thus, heated by direct flame radiation) and temperature difference between saturated steam and superheated steam is 100℃.

Convective Superheater:

Convective Superheater (placed in the convective zone of the furnace in the path of hot flue gas) increases the temperature of the steam to the desired temperature of 500℃ in the Loeffler boiler.

Superheating the working fluid increases the average temperature of heat addition. Thus the efficiency increases.

Reheaters:

Quality of steam at High-Pressure exit is achieved by reheating cycle which increases the efficiency of the cycle.

Turbine:

- Turbines transform the energy of steam into work.

- High-Pressure Turbines: extracts energy from High-Pressure superheated steam received from the main steam system.

- Turbines are composed of nozzles and blades in successive fashion to extract maximum work from the steam. However, the pressure decreases till the steam reaches the end of the turbine.

- low-pressure Turbines: extract work from low-pressure steam exiting High-Pressure turbines.

Steam Main:

Steam Main is a steel pipeline that carries steam from a steam boiler to steam turbines.

Fan Blower:

Fan ( Blower ) directs heated air into the combustion chamber for the combustion of fuel.

Chimney:

Chimney provided for the exhaust gases to be released into the atmosphere.

Loeffler Boiler Working Principle:

The flue gases ( involving CO2, H2O, O2, N2 ) from the combustion of fuel ( generally pulverized coal or natural gas ) are utilized for superheating the steam and in the economizer, preheater, and reheater section. The flue gases are then released into the atmosphere via Chimney.

Air is preheated in the Air Preheater by utilizing the energy of the flue gases from the combustion chamber. The Fan is employed to direct the preheated air into the combustion chamber for combustion of pulverized coal or Oil Fuel with increased combustion efficiency.

The feedwater is pumped into the Economizer with the help of a High-Pressure Feed Pump, where the exchange of energy takes place between the flue gases and the feedwater.

The feedwater is then drawn to the Evaporating Drum. In the evaporating drum, there are a number of nozzles that spray the water. This preheated feedwater is converted to steam ( by using the superheated steam as discussed later ) and is circulated to the Radiant Superheater by the Circulating Feed Pump.

The steam is superheated by passing through Radiant Superheater (through flame radiation) and Convective Superheater by utilizing the energy of flue gases from the combustion chamber, raising the temperature to 500°C.

The superheated steam is then passed through Steam Main to the prime mover ( turbine ) for electricity generation purposes. However, only 1/3rd of the total superheated steam is directed to the turbine. Rest 2/3rd is directed to the evaporating drum and is employed for evaporating the feedwater into steam.

After expansion in the High-Pressure turbine, the steam goes for reheating in the reheater cycle and is again redirected to the low-pressure turbine, the exhaust of which has sufficient energy to be used as process heat.

Loeffler Boiler Working Video:

Advantages of Loeffler Boiler:

The following advantages of Loeffler Boiler are:

- Loeffler boiler can use salt water for steam generation.

- This boiler can carry a higher concentration of salt than any other type.

- The deposition of salt and sediments on the inner surfaces of the water tubes is eliminated (which was the major difficulty experienced in the LaMont boiler).

- Using nozzles to distribute superheated steam in the evaporating drum for steam generation shuns priming and sound.

- Capable to react rapidly to sudden variation in load.

- More compact than indirectly heated boilers having a natural convention.

Disadvantages of Loeffler Boiler:

The following disadvantages of Loeffler Boiler are:

- Tightness of High-Pressure gas passage is essential.

- Using Evaporating Drum makes the whole setup bulky and costly

- The heat transfer rate decreased due to bubble formation.

Applications of Loeffler Boiler:

Loeffler Boilers with a generating capacity of 100 tonnes/h of steam, operating at 140 bar and 500°C have already been commissioned. This boiler can carry higher salt concentration than any other type and for its compact size, it is suitable for land or sea transport power generation. These boilers have marine applications and are used in the textile and medical industries.

Internal Resources:

- Water-tube boiler

- Fire Tube boiler

- Lamont Boiler

- Babcock and Wilcox Boiler

- Lancashire Boiler

- Cochran Boiler

- Benson Boiler

- Cornish Boiler

Reference [External Links]:

- https://en.wikipedia.org/wiki/Water-tube_boiler

- https://www.nationalboard.org/index.aspx?pageID=134&ID=286

- https://en.wikipedia.org/wiki/Fire-tube_boiler

Conclusion:

Here we studied Loeffler Boiler in detail, the term we studied are Definition, Parts, Working Principle, Types, Advantages, Disadvantages, and Application. Let me know what further I can help you with. Till then if this article helps you please share it with your friends and family. Thank you for reading.

Discussion about this post