Hello, reader in the last article we explained the piston of the engine in detail. The connecting rod is also a part of an IC Engine. Today we will study the Definition, Parts, Types, Function, and Material.

And at the end of the article you can download PDF version.

So lets start with the definition first,

Connecting rod Definition:

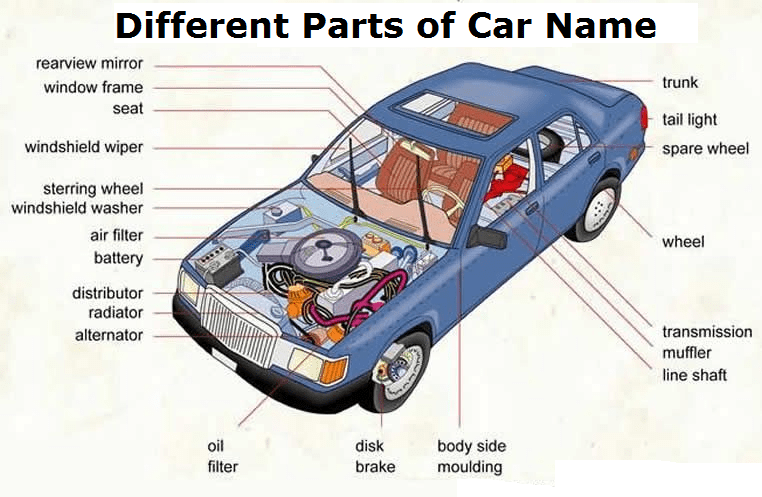

The connecting rod is defined as it is a mechanical component that helps to connect the piston and crankshaft of the engine. In other words, you can say it acts as an intermediate member between the piston and the cylinder.

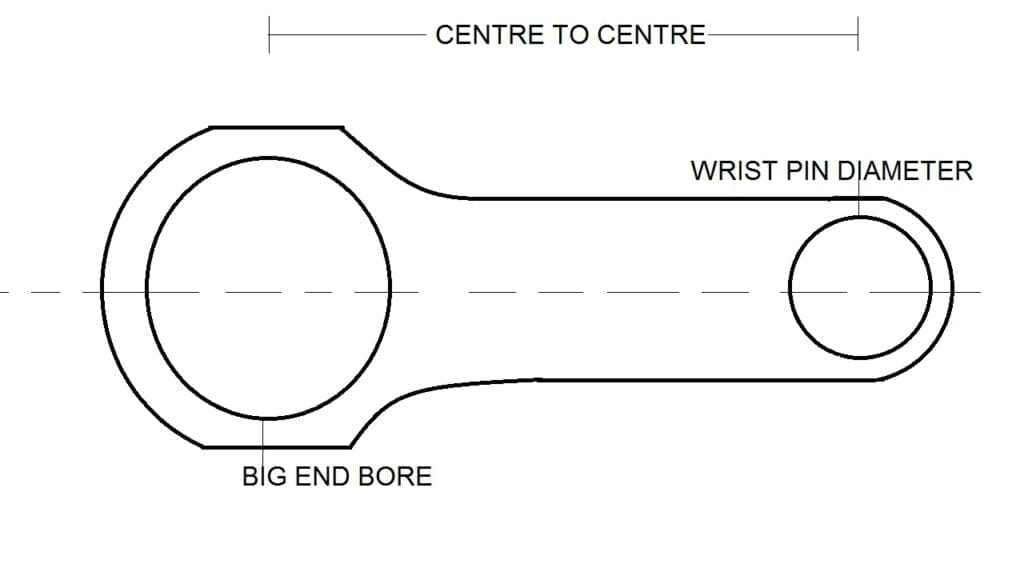

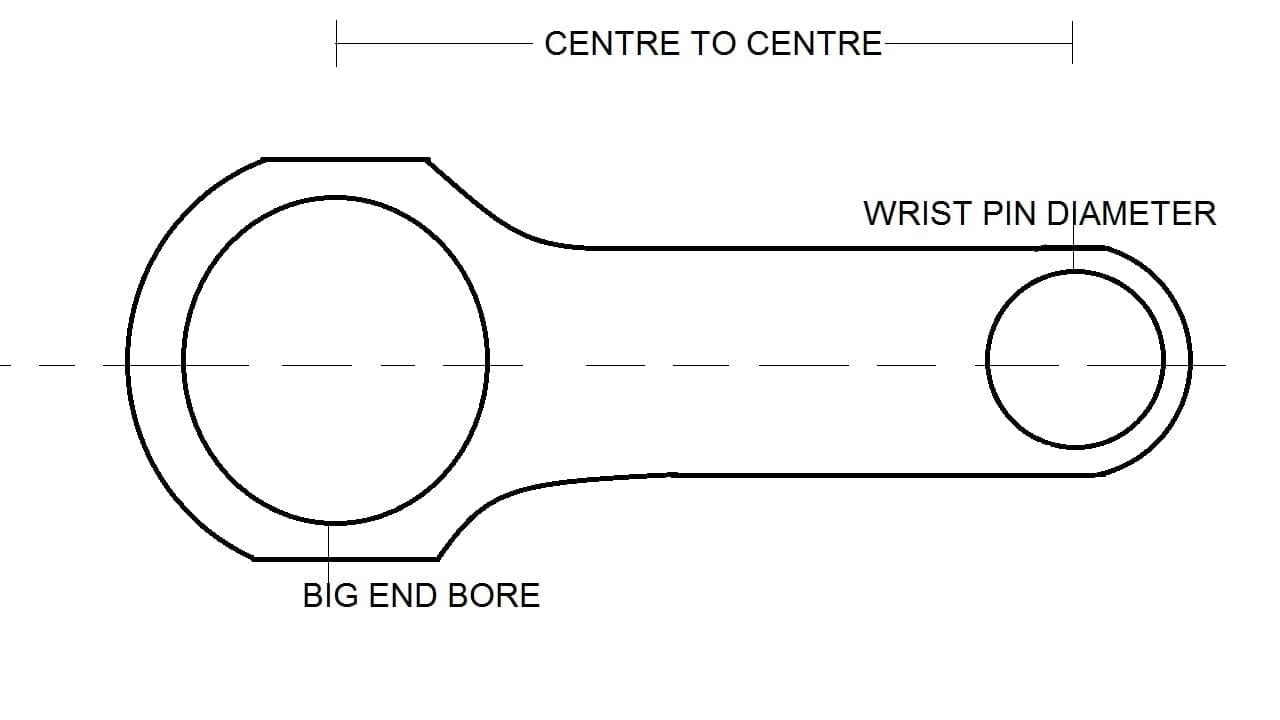

Connecting rod Parts or Construction:

The following Construction or Parts of Connecting Rod is:

- Small End

- Bigger End

- Bearing insert

- Bushing

- Bolt and nut

- I-section beam

- Shank

It connects to one side with the pistol pin and the other side connects with the crank.

Small and Bigger End:

The rod which is facing the piston side is termed as a small end. And which is on the crank side is termed as a bigger end.

Bearing insert:

There is a bearing insert inside the bigger end which is attached to the cap, which is called the bearing insert.

Shank:

Apart from this, both the bolt and nut acts to connect the connecting rod and cap. And we use a section beam which we call a shank. The cross-section of the rod can be rectangular, tubular, and be a circular section.

The length of the rod depends on the ratio of (l/r)

Where, l = length of the shank and r = radius of the shank.

If the length is low then the l/r ratio will also be low, Due to this, the rod will increase in angularity due to which the side thrust on the piston will increase which causes increasing linear wear.

In the same way, if the length is more then the ratio of l / k will be more. Due to this, the angularity of the rod will decrease, so due to this, the side thrust on the piston will also decrease which causes less wear is obtained in the cylinder.

Note: The higher the length, the more the engine size will also increase, so the ratio of l/r is kept between 4 and 5.

Bush and bearing:

Bush and bearing are installed at both ends of the connecting road. The phosphor bronze bush is placed near the small end of the rod and the piston pin is connected with the smallest end piston.

The big end stays connected with the crank and the big end of the rod is divided into two half which we can easily mount above the crank bearing shell.

And then after connecting the rod with the crank in the last, both sides of the big end are joined with the help of nuts and bolts. So by combining all these we prepare the connecting rod.

Connecting rod Function:

The pull and push in the piston receive the piston pin, then the connecting rod acts as the transfer of the pull and pushes from the piston pin to the crank pin. That is, in any internal combustion engine with the help of it, the reciprocating motion is converted to rotary motion.

In the design requirements of the rod, the bearings are connected with the cap so that we have accurate and smooth rotation. Same as bush near the smaller end to fit to get accurate and smooth motion.

So It is connected to the piston pin or gudgeon pin on one side. And connected to the crankshaft on the other side, so the movement of the piston gives to the crank through the rod.

Connecting Rod Material:

These are the five materials which we use in the connecting rod:

- Mild carbon steel,

- Aluminum alloy,

- Alloy cast iron,

- Graphite cast iron and

- Alloy steel.

Manufacturing process: It is made from the drop forging process.

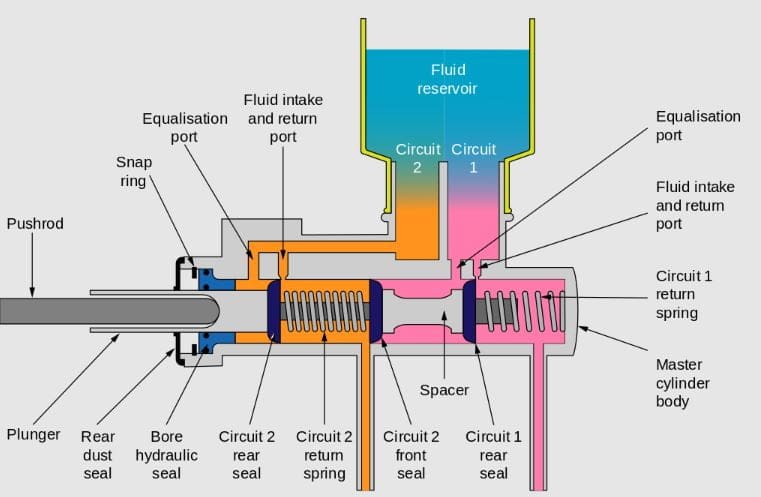

Connecting rod Lubrication Function:

Bearing is attached to both ends of the rod so we lubricate the bearing in two ways.

- Splash lubricant

- Pressure lubrication

Splash lubrication:

Splash lubrication is done in the bearings in the big end of the crankshaft. And pressure lubrication is done in the small end bearing.

In splash lubrication, a sprout is placed at an angle, so that whenever the rod is down, the sprout is inserted into the lubricating oil.

So that the lubricating oil reaches the end of the bearings through the sprout. So when this rod goes up, the sprout causes the oil to splash, so we call it to splash lubrication.

Pressure lubrication:

In pressure lubrication, the end of the connecting rod has a hole near the bearing, And there the oil pressure is sent for lubrication which we call pressure lubrication.

Connecting rod Types:

This mainly of two types depending on the structure

- Single piece and

- Two pieces or split piece of connecting rod

Single piece connecting rod:

The big end of a single rod is made in one part instead of two. A needle bearing is fitted in it

Two-piece or split piece of connecting rod:

This type of connecting rod in which consists big end is made up of 2 pieces

Let us also know about the bush and bearing of the connecting rod:

A bush made of bronze or gunmetal is fitted between the connecting rod’s small end and piston. The bearing on the big end is made up of :

- Low carbon steel

- Copper lead alloy

- Copper tin alloy

- Tin antimony alloy

- Tin antimony copper alloy

- Lead indium alloy

- Lead bronze alloy

- And tin aluminum alloy

Apart from this, the bearing is in 2 pieces, it is placed near the big end of the rods. The flange is used to prevent the moment between the two pieces.

Bearing clearance:

It is mainly two types

- Running bearing clearance

- Side bearing clearance

Running bearing clearance

It is the clearance between bearing and the crank surface.

Side bearing clearance

This is the clearance between the crankpin and the crank arm (Big end) thrust side.

Connecting Rod Inspection:

Normally the connecting rod is not crooked but can sometimes be bent due to preignition and detonation. Then it is inspected while fixing it.

Discussion about this post