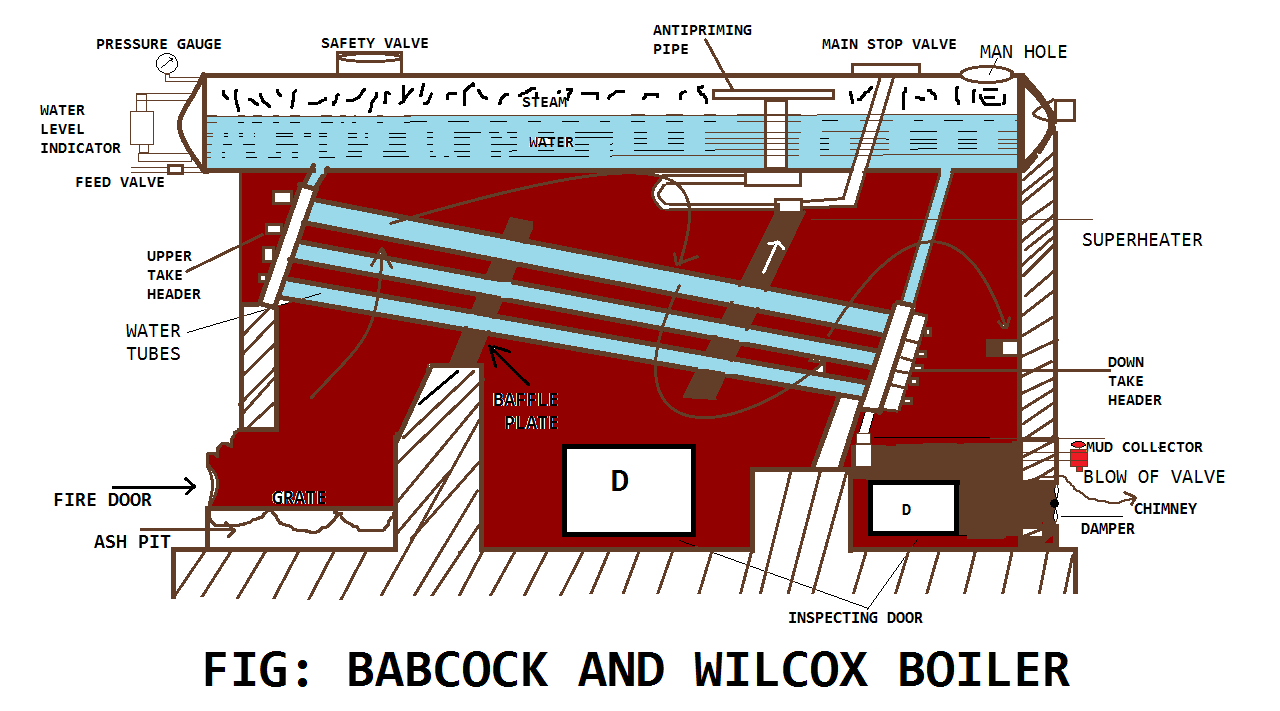

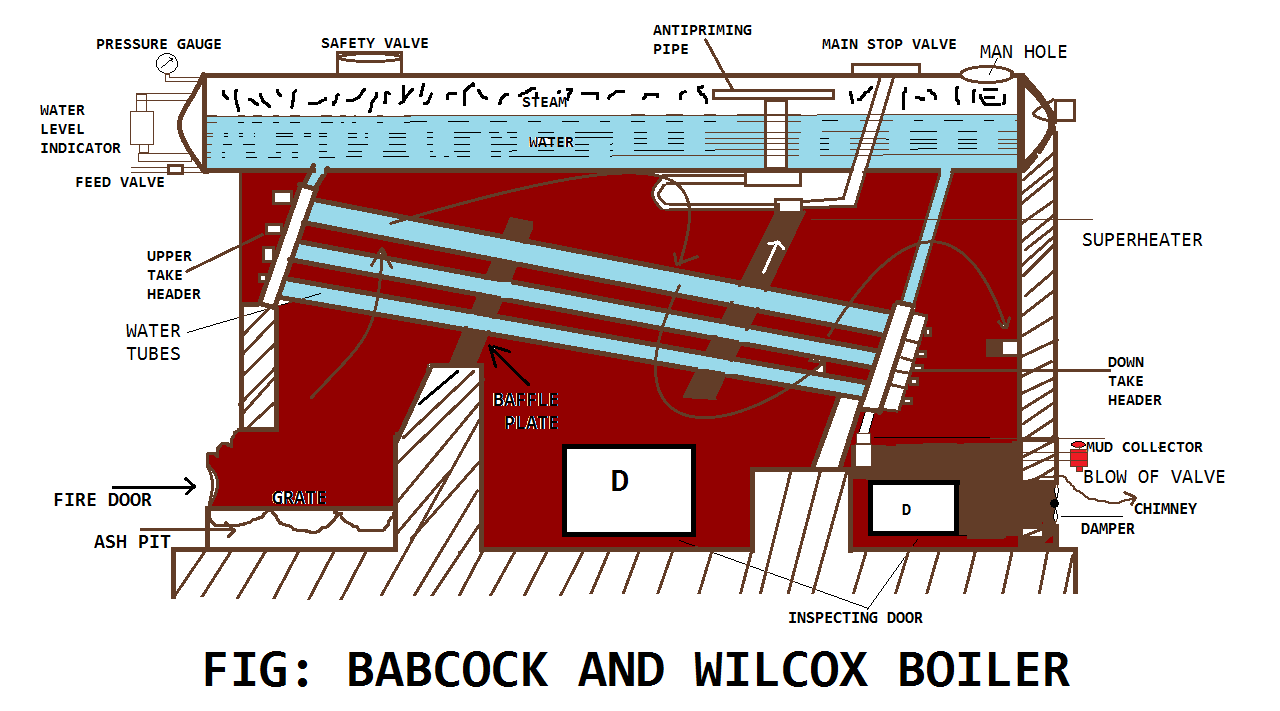

Babcock and Wilcox Boiler is a simple water tube boiler in which water is flowing in the tube and hot gases surround them.

Here we are going to study Definition, Construction or Parts, Working Principle, Application, Advantages, Disadvantages of Babcock and Wilcox Boiler in very detail.

At the end of every article, you can download PDF.

Let’s start with the definition first,

Babcock and Wilcox Boiler Definition:

Babcock and Wilcox Boiler is a horizontal type drum axis, stationary, high pressure, natural circulation, solid fuel-fired water tube boiler in which coal is burned to heat the water for changing the phase into steam and later that steam is used for power generation.

Now comes to the construction,

Babcock and Wilcox Boiler Parts or Construction:

Babcock and Wilcox Boiler consist of the following Parts or Construction:

- Drum

- Inspecting Door

- Fire door

- Grate

- Ash pit

- Baffle Plate

- Upper take header

- Down header

- Feed Valve

- Water level Indicator

- Pressure gauge

- Safety Valve

- anti Primimg Pipe

- Main Stop Valve

- Manhole

- Superheater

- Drum

- Mud collector

- A blow of valve

- Damper

- Chimney and more

Let us study one by one,

Drum:

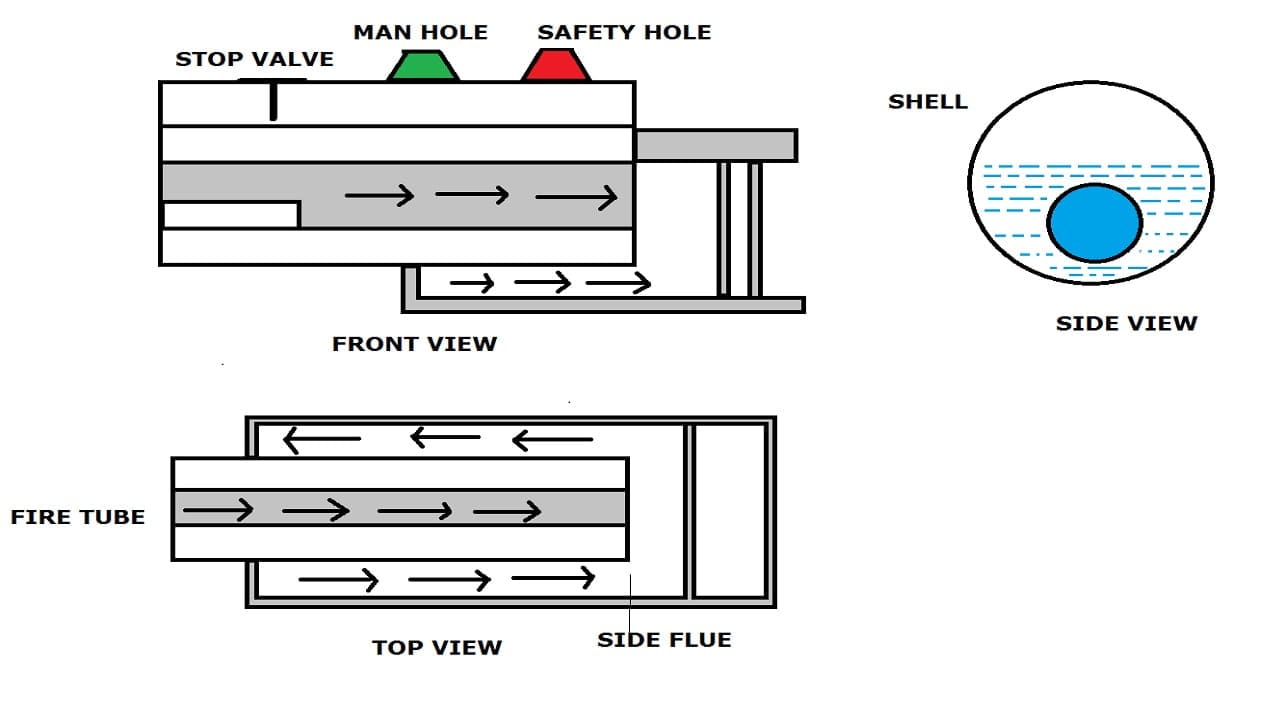

It is a horizontal axis and it contains water and steam as you can see in the diagram. The water drum is connected by a tube with an uptake header or riser at the other end.

Inspection Door:

The inspection door is provided for inspecting and cleaning the boiler. When the boiler parts get damaged and it is not functioning properly then through the inspection door the boiler specialists enter into the boiler and fix the damage parts.

Fire Door:

The Fire door is basically for providing the fire to start burning of fuel. Basically here we provide the solid fuel for burning.

Grate:

It is basically known as the door for placing the fuel coal.

Ash Pit:

After the burning of fuel coal, the completely burned fuel which becomes ash now will come to the ash pit. The ash pit is located below the grate.

Baffle Plate:

The baffle plate is present in the water tube boiler. The main function of the baffle plate is to divert the flue gases direction so that from one side to another side hot flue gases can easily go.

Upper and Down take header:

Upper take header connected to the drum from a very short pipe and down take header is connected to a long pipe.

The water comes from the drum through a long pipe to the down take header and it flows through the entire tube.

The steam formed will go up by a shorter tube (Upper take header).

Water level Indicator:

The Water level indicator is a measuring instrument. It measures the level of water and gives detail of the level of water.

Pressure gauge:

We use this instrument in several places. The works are to measure the pressure of the steam.

Safety Valve:

The safety valve is to prevent an increase in steam pressure.

Main stop valve:

The steam stop valve regulates the supply of steam outside to the boiler. First, from the boiler, the steam generated comes to an anti priming pipe here some parts of water particles will be removed and it completely remains dry steam then further this steam is used for needed place.

Man Hole:

Manhole is a very important part of the boiler. When parts or accessories get damaged or not working, then a boiler specialist engineer enters through the Man Hole and fixes the damaged parts.

Anti Primimg Pipe:

Anti priming pipe is provided in the boiler for extracting steam from the boiler is only dry saturated steam.

Mud Collector:

The impurities or contamination from the water will store here.

A blow of valve:

It is attached to the mud collector. Water contains some impurities like mud, sand, and salt. Due to the heating of water, these impurities deposited in the ground that creates a problem and it has to be removed.

So the Blow-off-valve is used for removing impurities from the mud collector.

Damper:

A Damper is here for removing the smokes from the boiler and it sends to the chimney.

Chimney:

The smoke released by the damper now comes to the chimney. From here smokes are released to the atmosphere. After studying construction now let’s have an overview of how it works,

Babcock and Wilcox Boiler Working Principle:

The working is, first the fuel (coal) is placed at the grate, and water is supplied to the drum. Now from the fire door ‘fire’ is supplied, to start burning of coal. The start burning of coal produces hot gases.

Water from the long pipe as you can see in the diagram (down take a header) is coming and impurities parts get into the mud collector and water is moving to the tubes.

The temperature of the flue gases increasing so water starts gets heating.

Here the baffle plate is placed to divert the flue gases direction to another side for an equal amount of flue gases for heating.

The water starts evaporating in the tube as increases the temperatures.

The steam formed will go up by short pipes to the drum and to the superheater to form completely dry steam and during these process circulation of water is on. The smoke released by the damper to the chimney and to the atmosphere.

Babcock and Wilcox Boiler Working Video:

It has some advantages and disadvantages too:

Babcock and Wilcox Boiler Advantages:

The following advantages of the Babcock and Wilcox Boiler are:

- The overall efficiency of the Babcock and Wilcox boiler is high.

- This boiler occupies less space.

- The tubes used in the boiler can be exchanged easily when it gets damaged.

- A steam generation or production is high nearly around plus 20 tonnes per hour.

- The draught loss is limited.

- The transportation of the boiler is easy.

Babcock and Wilcox Boiler Disadvantages:

The following disadvantages of Babcock and Wilcox Boiler are:

- This boiler is not suitable for salty, Impure, and Sedemetry water. If these go to the boiler the overheating problem can occur that’s why water treatment is necessary before inserting water for the working process.

- The maintenance and Installation cost is more.

Babcock and Wilcox Boiler Application:

This boiler is used for power plants for the generation of electricity and some other industries too.

Babcock and Wilcox Boiler Sailent Features:

The following Silent features of this Boiler are:

- Babcock and Wilcox Boiler, Overall efficiency is high compare to other fire tube boiler.

- The tubes which get defective can be replaced easily.

- The draught loss is minimum.

- The water tubes are kept inclined to 15 degrees for the circulation of water.

- The operating pressure and steam generation are high compare to another boiler.

Also, you can read related articles:

- Water-tube boiler

- Fire Tube boiler

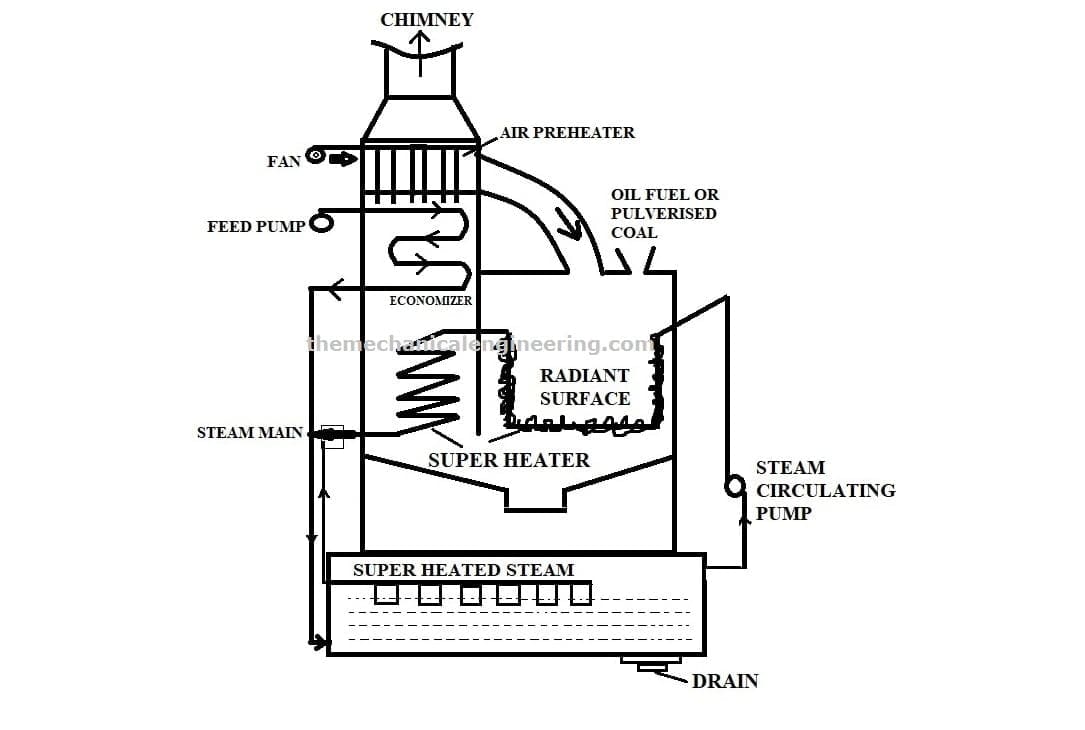

- Lamont Boiler

- Loeffler Boiler

- Lancashire Boiler

- Cochran Boiler

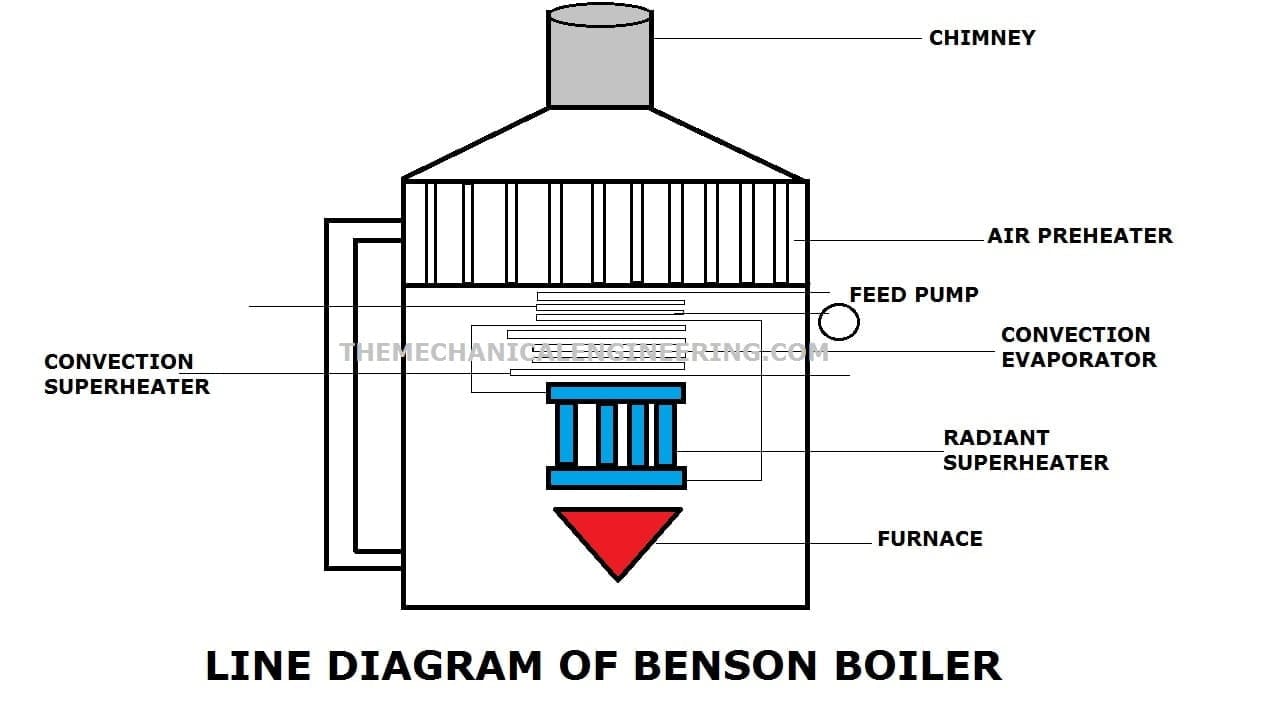

- Benson Boiler

- Cornish Boiler

Reference [External Links]:

- https://en.wikipedia.org/wiki/Water-tube_boiler

- https://www.nationalboard.org/index.aspx?pageID=134&ID=286

Conclusion:

Here we studied Babcock and Wilcox Boiler in detail. Let me know what further I can help you with. Till then if this article helps you please share it with your friends and family. Thank you for reading.

Discussion about this post