Measuring tools are devices used to measure and compare the quantities of real-world objects and events. The measurement gives a number to quantify the item under study and the referenced unit of measurement.

Measuring tools with perfect methods that describe the use of the tools are how these relations of numbers are obtained. A single error in measurement can ruin the whole project and in order to avoid such errors, it is required to be well-versed in the different types of measuring tools and their functions.

The purpose of measurement tools is to make our lives better and safer, and hence they enhance the quality and quantity of life.

Arguably, the ability to measure physical properties accurately has a direct correlation with the survival value that thus gives humans an adaptive, evolutionary advantage honed through many years of natural selection.

The overall purpose of measurement can be categorized into measurement being in the service of quality, monitoring, safety, design, assembly, and problem-solving.

It is noteworthy that measurement sometimes serves multiple purposes. Therefore, to help you introduce these tools, we have gathered a list of essential measuring tools with their use.

Some of the most essential measuring tools in today’s industry are Caliper, Compass, Micrometer, Pressure gauge, Speedometer, Tape measurer, Measuring squares, Odometer, Thermometer, and many more.

What are the Different Types of Measuring Tools?

#1. Measuring Tape

The measuring tape is among the most versatile measuring devices. It is a ruler that can be folded into any form and it is used to measure length or width.

In the simplest form, they consist of a fabric or plastic ribbon with measures in inches, centimeters, and/or millimeters written on.

One end of the measuring tape usually consists of a hook or a lock to get an error-free measurement.

A spring-loaded housing that can be clipped onto a belt is utilized by the self-detecting metal tape.

The most frequent tape measures are of the size with lengths of 12 feet, 25 feet, or 100 feet.

The shape makes it very convenient to carry huge length measurements in your pocket, also allowing you to measure curves and corners.

In today’s fast-evolving technology, it may be found almost anywhere, even in miniature items.

#2. Compass

A compass is a drawing instrument technically used for drawing circles and arcs in geometry. It is a very useful measuring tool that may be used for a variety of tasks such as algebra, drafting, navigation, and other things.

The word is derived from the Latin word compasses which means ‘circle’ in Latin. It is a very familiar word in the field of architecture as well. Its utilization extends to the shipbuilding and carpentry processes as well.

Compasses have two “legs” which are used to adjust or change the radius of the circle drawn and the legs are made up of metal.

One leg is used to hold the center of the circle and the other leg is measured to the distance of the radii and used to draw the circumference. It is also utilized as a divider to separate distances, especially on maps.

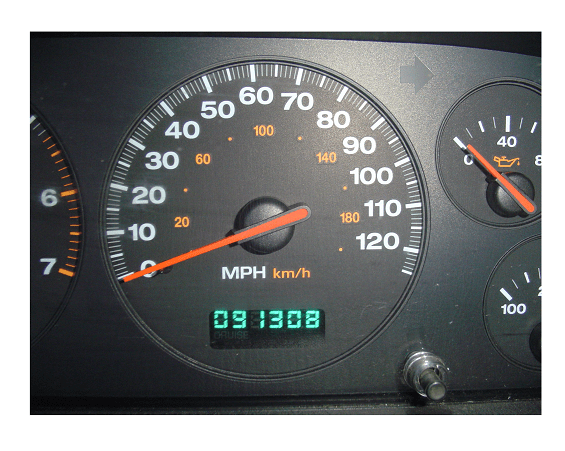

#3. Speedometer

The speedometer is a very common type of measuring tool used for determining and displaying a vehicle’s speed.

Since the 1900s, motor vehicles have been equipped with these and used as the standard equipment. The speedometer’s mechanism revolves around a round magnet that rotates 1,000 times each mile of vehicle travel.

The types of speedometers have eventually increased with time, employing different names and different speed-sensing mechanisms. These measuring tools can be classified among precision measuring equipment.

Upon classification, speedometers in the modern age consist of mainly two types- Mechanical and Digital Eddy current speedometers.

While mechanical speedometers worked on the mechanism of the rotating magnet, the eddy current speedometer works on the measurement of rotational speed. This is done by measuring the speed generated by the transmission and delivering the information to the drive cable.

The drive cable is the attachment between the transmission and instrument cluster in the vehicle’s deck. The instrument cluster contains a needle, which is held in place by a hairspring and is used to indicate the vehicle speed.

Another type of speedometer is an electric speedometer, which receives its data from the vehicle speed sensor instead of the drive cable.

Its located near the transmission output shaft and has a magnetic field around it which creates impulses. For every 40,000 impulses, the odometer increases by one mile.

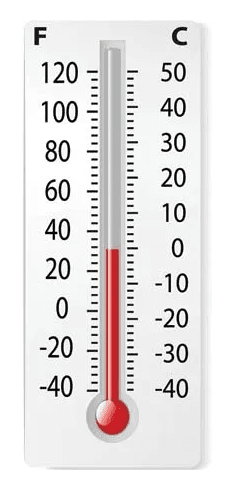

#4. Thermometer

As the name suggests, thermometers are devices used to measure temperature. It is an essential device in fields such as manufacturing, scientific research, and medical practice.

These are often inexpensive, long-lasting, and accurate, and calibration is simple. The working of a thermometer is made up of two parts: a temperature sensor to detect the temperature change, and a transformation of that change into a numerical value (Fahrenheit and Degree celsius unit.

The medium used for the working changes with the type of thermometer. The major types include Liquid thermometers, Dial thermometers, and electronic thermometers.

Liquid thermometers are the simplest, typically consisting of a liquid in a tube that rises and falls against a linear scale (one with equally spaced divisions) marked with the temperature. The liquids used are usually mercury or alcohol-based.

Dial thermometers work like a gauge with a metallic pointer and metallic strip. The metallic strips are designed to expand and bend with the temperature change. The metallic pointer expands with the increase in temperature and the more the pointer pushes up the scale.

Electronic thermometers were designed to overcome the time delay caused by the other methods.

These work on the principle of resistance of a piece of metal with the temperature change. These work by putting a voltage across its metal probe and measuring the amount of current flow in it. The higher the temperature, the higher the resistance.

These thermometers have a microchip inside to measure and convert the resistance into temperature. Thermometers are extensively utilized in technology and industry, meteorology, medicine, and scientific research to monitor processes.

#5. Digital angle gauge

Angle gauges were established to measure difficult angles accurately and to create reliable data. These types of equipment made it simple to measure any angle surface.

A digital angle gauge is more accurate, easier to operate, and faster than an analog angle gauge. These have a powerful magnetic base along with automatic calibration settings for establishing the correct bevel and miter angles on powered saws.

Digital angle gauges are inexpensive along with being extremely precise.

A digital angle gauge consists of a gauge body that has a reference surface that is engageable with an object to be measured for angular inclination.

An angle sensor and processor mounted in the body determine the inclination angle of the object with which the reference surface of the gauge body is engaged. These have accuracy in the range of ±0.1- 0.2.

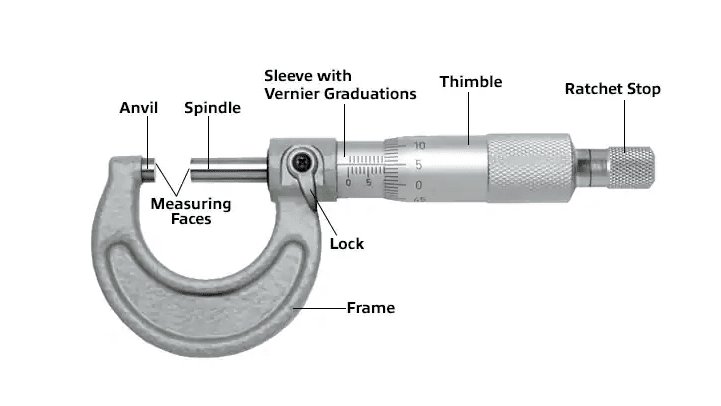

#6. Micrometer

A micrometer is a device used for measuring linear dimensions such as lengths, thickness, and diameters. These types of measuring tools look like a caliper, but it screws down, instead of sliding mechanism.

It consists of a ratchet knob attached to the spindle, the spindle is connected to the anvil via a C-shaped frame that has a movable jaw. The movement of the setup is controlled using the ratchet.

The object to be measured is placed in between the spindle and the anvil. The spindle is extremely accurate, and the ratchet knob is adjusted to revolve the spindle until the object is locked in between the anvil and the spindle.

The scale on the ratchet knob is used to measure the dimension. They are sometimes known as screw gauges or calipers due to their resemblance in structure.

In digital micrometers, the work distance between the two caliper heads is quickly measured. It also allows measurements accurate up to three or four decimal places.

Devices such as Micrometers, along with dials, verniers, and digital calipers, are commonly used for precise component measurement in mechanical engineering and manufacturing, as well as in most mechanical trades.

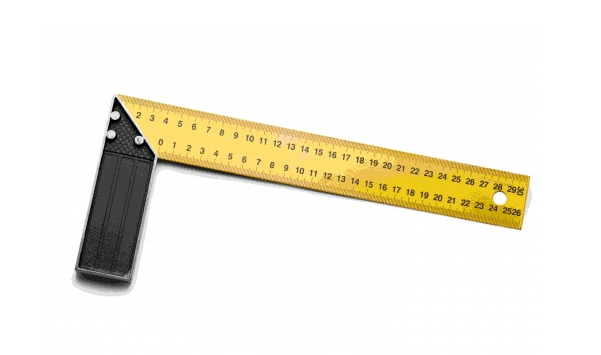

#7. Measuring Squares

Measuring Squares devices that consist of two straightedges set at right angles to each other. Squares are often used for measuring a 90° angle, whereas a miter square is used to measure and refer to a 45° angle.

Its application is to incorporate a straight line or angle while drawing or marking the dimensions. Some special types of these tools are combination squares, drywall squares, framing squares, and speed squares.

Carpenters and machinists extensively use them to analyze the precision of right angles when drawing lines on the material before cutting.

A scale (ruler) for measuring distances or calculating angles is also one sort of square measuring device. These are commonly referred to as the carpenter’s square.

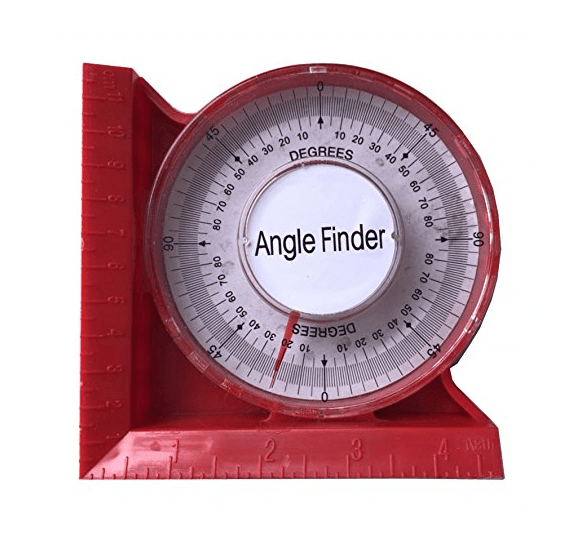

#8. Angel Locator

The angle locator is also referred to as an angle finder. It is used to measure angles and replicate the angle of an existing area. These are commonly utilized in the construction or carpentry industry.

This measuring tool consists of a magnetic base that allows them to be attached to metal measuring objects. It is a manual tool with a digital display that needs to be placed at the ends of the workpiece and use the readings obtained to determine your angle.

The use of the angle locator allows easy at-a-glance measurement of angles from 0° to 90°. This device becomes essential when there is a need to find an angle inside a closet or small space, so having a tool like this will greatly simplify the process.

#9. Bubble Inclinometer

As the name implies, an inclinometer is a device used to measure an inclination. In other words, an inclinometer is used for measuring angles of slope, elevation, or depression of an object concerning gravity’s direction.

Clinometers can measure both inclines and declines. The three different units of measure are namely degrees, percentage points, and topos.

It is an essential and smart choice to determine a particular inclination or declination. These are specifically designed to measure the range of motion of a joint and can also be used to measure the stability of the grade.

To identify the range of motion of a joint, the bubble inclinometer is set to zero, and then the change in slope is determined by the difference as it undergoes its changes.

This application is often utilized by sports therapists to determine a healthy range of motion at critical junctures of the body. Other applications can be found in the aircraft industry and game controllers.

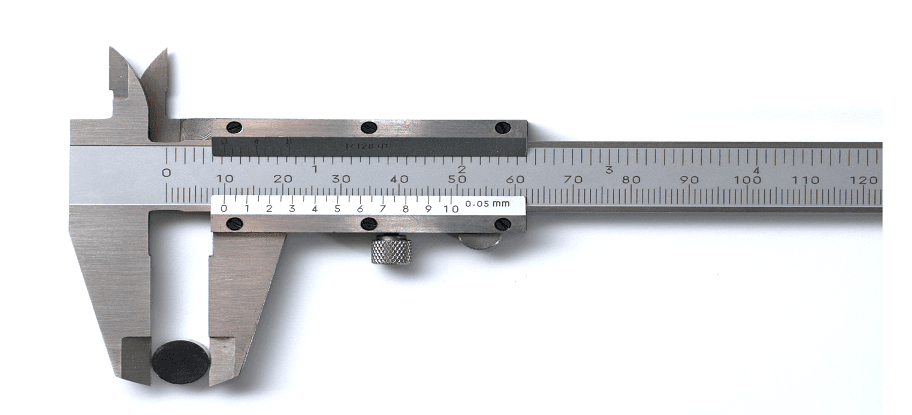

#10. Caliper

A caliper is an instrument used to measure the dimensions of an object such as thickness, outside and inside diameter, length, width, and depth. These measuring tools facilitate multiple-dimensional measurements and are usually made of steel.

The applications of these tools are used in engineering, medicine, construction, household, and metalworking.

The object to be measured is placed in between the tips or teeth of the caliper.

By adjusting the tips of the calipers to fit across the object to be measured, the total length can be easily measured with the help of a fixed ruler.

The measurement can be read on a controlled scale, dial, or digital display in different types of calipers. Moreover, calipers can be used for measuring the separation between two surfaces of an object.

The caliper is removed after the tips have been adjusted to the ends of the object being measured and the reading is obtained by measuring the distance between the tips using a measuring tool, such as a ruler.

There are numerous varieties of calipers in terms of dimensions, including outside, inside, spring, transfer, and hermaphrodite calipers.

The different variants of the caliper in terms of applications include the vernier scale, digital caliper, compass, dial caliper, odd leg caliper, and micrometer caliper.

#11. Level

The level is a type of measuring tool that is used to establish or verify points in the same horizontal plane in a process known as leveling, indicating the horizontal plane.

It is an optical device that consists of air bubbles in a liquid medium to display measured results.

It is used in conjunction with a leveling staff to establish the relative height levels of objects or marks. It is used to measure height differences and to transfer, measure, and set heights of known objects or marks in the fields of construction.

It consists of a tube that is sealed and fixed horizontally to a block of wood with a smooth bottom surface.

When the glass tube of the level is tilted, the adjustment in the horizontal is indicated by the movement of the bubble.

Builders generally use longer-level instruments that range from 2-, 4- or 6 feet in length.

Modern automatic levels work on the principle of establishing a visual level relationship between two or more points, for which an inbuilt telescope and a highly accurate bubble level are used to achieve the necessary accuracy, also the modern automatic versions self-compensate for slight errors in the coarse leveling of the traditional instrument, and are thereby quicker to use.

These are utilized in construction works, woodworking, and metalworking shops.

#12. Laser Level

The laser level is a controlling and measuring tool that consists of a rotating laser beam projector that is firmly entrenched in a tripod.

The leveling is as per the accuracy of the tool and it projects a fixed green or red beam in a plane about the horizontal and/or vertical axis.

Certain types can measure the distance from the unit up to the end of the laser beam. This avails a fast and accurate solution for worksite distance measurement.

Types of laser levels are tower mounted and rotary laser level. A tower-mounted laser level is used along with a sensor on a wheel tractor-scraper in the process of land laser leveling.

A rotary laser level is more of an advanced laser level. It spins the beam of light in such a way that it gives the effect of a complete 360-degree horizontal or vertical plane.

This causes the level to illuminate not just a fixed line, but a horizontal plane. Laser levels are commonly utilized for leveling and aligning applications in the construction and surveying industry.

#13. Odometer

The odometer is a measuring device used in automobiles to measure the distance traveled by a vehicle, such as a bicycle or a car. The distance traveled by car is used for maintenance purposes. It can be produced either electronically, mechanically, or by a combination of both (electromechanical).

Earlier, most odometers used to work by counting wheel rotations and assuming that the distance traveled is the number of wheel rotations times the tire circumference, which is a standard tire diameter times pi (3.1416).

But it could create errors if nonstandard or severely worn or underinflated tires are used. Mechanical odometers are the most common type. It is mounted by a flexible cable made from a tightly wound spring in bikes.

In cars, mechanical odometers are a pair of gears with an incredibly excess gear ratio. Such odometers are being replaced by digital odometers that offer additional features and are cheaper, but they have limited life capacity.

In modern-day cars, electronic odometers are used. These contain a toothed wheel mounted to the output shaft of the transmission and a magnetic sensor that counts the pulses as each tooth of the wheel goes by.

The distance covered (along with a lot of other data) is a single-wire single-wire communications bus from the engine control unit (ECU) to the dashboard.

The trip meter is a deviation from the odometer yet a part of it. It is reset at any point in a journey, making it possible to record the distance traveled in any particular journey or part of a journey.

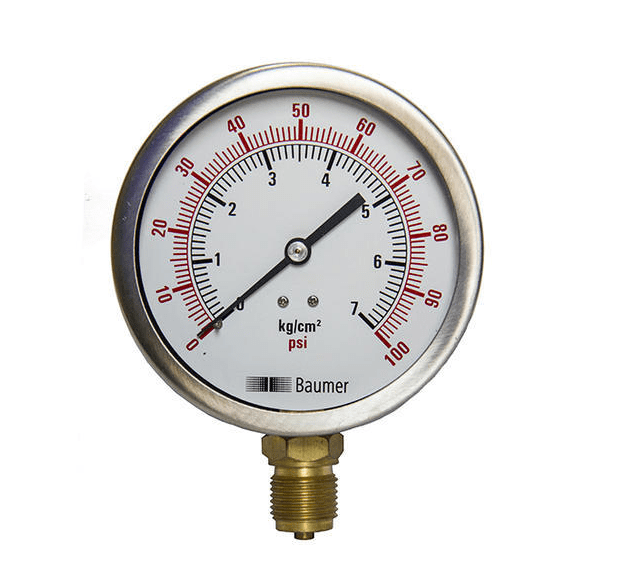

#14. Pressure Gauge

Measurement of the pressure means analyzing the force applied by the fluid on a surface. The purpose of the pressure gauge is to measure and display the pressure. These are used to quantify everything from altitude to air pressure to depth to blood pressure.

It is measured in units of force per unit of surface area and the unit is Pascal. Pressure gauges are mainly of four types, namely gauge, ambient, absolute, and differential.

These are nothing but measurements of pressure concerning various surrounding factors. Gauge pressure involves a vented environment with ambient atmospheric pressure.

Sealed pressure involves the measurement of pressure applied to a sealed chamber closed with atmospheric pressure.

In absolute pressure, measurements are conducted in areas in a vacuum chamber removed from air (generating absolute pressure) for a reading of input pressure.

The differential pressure measurement is the difference between two pressures, usually between ambient and those internal to a sensor.

A pressure gauge is easy to read and often appears on the screen rapidly. Hydrostatic and aneroid gauges are among the most common types of analog pressure gauges.

Important applications of pressure include refrigeration and heating systems which require constant monitoring of pressure.

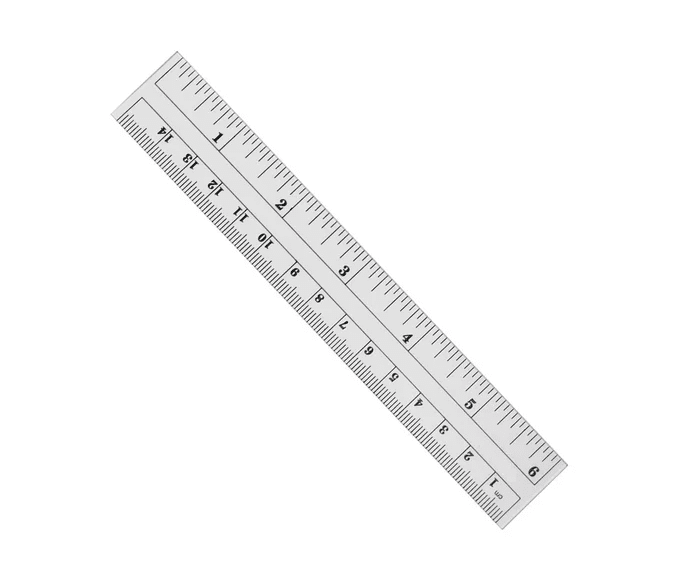

#15. Ruler

A ruler is a tool used to measure distances or draw straight lines in geometry and technical drawing as well as in the engineering and construction industries.

It is a staple in any workshop, acting as a basic tool for measuring length, drawing lines, and serving as a guide for cutting. The use of rulers dates back to 2650 B.C.

It is called ruler because of the meaning of the verb rule, “to exercise power” or “to control,” which came to also mean “mark with lines” in the 1590s. Commercially be termed as the most simple yet important measuring tools used in today’s industry.

The simplest purpose of measuring lateral dimensions plays an important role in the engineering and construction process. Commercially, they are mostly found in engineering, where they are used to ensure accurate measurements on flat surfaces.

The standard of measurement in a ruler is in both metric and customary units.

The distance on the line above is in centimeters and on the line below is in inches, and the interval in the ruler is called the hash mark. Rulers undoubtedly are probably the most semi-circle-shaped tool in use today.

#16. Protractor

Protractors are semi-circle-shaped measuring devices often made-up of plastic or glass. These are used to measure angles and are commonly marked with degrees.

Protractors that measure in radians are more mathematically oriented protractors that can be found on occasion.

A common protractor is shaped like a half circle, with an inner and outer scale, with marks indicating the range of 0 to 180 degrees. To measure an angle, the baseline is used as a pothe int of reference over which the baseline of the protractor is the angle.

Moreover, the center of the baseline should match with the vertices the s of tgla e and the angle should be counted from the side of the ray (Assumed in the case of a quadrilateral).

A tool called an angle protractor is used for more precise measurements often by engineers and designers. A further advanced protractor is a bevel protractor that has one or two swinging arms for measuring angles.

Discussion about this post