Introduction to Car Headlight:

A car headlight is a device used to illuminate the road ahead in vehicles and is located at the front end of the vehicle. These are also referred to as Headlamps. But in terms of usage, the headlamp is the term used for the light source device and the headlight is the term for the beam of light, which is produced and distributed uniformly by the device.

These are one of the most essential features of a car as they play a very significant role in ensuring safety and drivability.

According to the US NHTSA which is a traffic safety administration, half of all traffic-related fatalities occur in the dark, despite only 25% of traffic traveling during darkness.

The primary objective of using headlights is to illuminate the road ahead and facilitate a fatigue-free visual for the driver.

Car Headlights and other light sources are thus the visual components associated with vehicle safety. These require official approval and are not the components to tamper with.

The nature and position of the lights on the vehicle and their design, colors, and photometric values are regulated by law.

The use of headlights in automobiles dates back to the 1880s with the use of gas headlamps.

Headlights come in different shapes and sizes along with various types of lenses and bulbs. These characteristics are used to differentiate between the types of headlights along with the likes of focus, the energy required, and light color.

Let’s see what are different types of headlights used.

History of Headlights in Automobiles:

The earliest headlights were fueled using acetylene gas or oil and operated during the late 1880s as the lamps were popular because the flame is resistant to wind and rain.

Pockley Automobile Electric Lighting Syndicate, located in Birmingham England marketed the world’s first electric lights as a complete set in 1908. It consisted of headlamps, side lamps, and tail lights and was powered by an eight-volt battery.

Cadillac integrated an electrical ignition and lighting system in their vehicle, which formed the modern vehicle electrical system in 1912.

The Guide Lamp Company integrated low-beam or dipping headlamps in 1915. The 1917 Cadillac model allowed the dipping light to be switched using a lever inside the car rather than requiring one to get out of the vehicle.

The foot-operated dip switch was introduced in 1927 and it became a standard.

Steering-linked lighting levers were integrated into the 1947 center-mounted Tucker Torpedo’s headlight.

In 1962, European headlamp makers introduced the halogen bulb for vehicle headlight use. These became available for use in the United States years later in 1979.

BMW introduced the High-intensity discharge (HID) systems in the BMW 7 Series in the early 1990s.

Different Types of Lights & Headlights used in the Car?

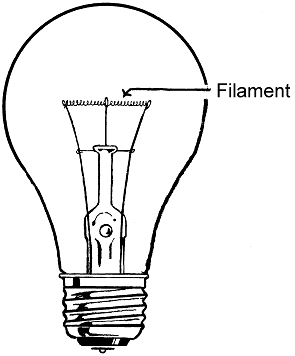

#1. Filament bulb:

A Filament headlight contains a thin tungsten filament that is surrounded by a vacuum in a glass filament capsule that is used, due to its extreme resistance to high temperatures.

These simple filament bulbs were used in the oldest cars and are similar to the bulbs used for household purposes.

These bulbs are heavy duty usually found in sealed beam reflective headlights and the tungsten filament is suspended in a vacuum.

The working of the filament bulb headlights depends on the passing of electricity through the tungsten filament inside the glass capsule. When electricity is passed through it, the filament heats and gives off light.

These headlights produce a yellowish-colored light and consume more energy for their function.

Moreover, these are generally much hotter than other headlights. The tungsten evaporates during the process and is deposited on the inner surface of the bulb.

This causes the bulb to blacken out, which makes the filament weak and eventually break. As a result, many European countries have begun a phase-out of these bulbs due to inefficiency.

#2. Halogen Light:

A halogen headlight contains a thin tungsten filament that is surrounded by a halogen gas in a glass filament capsule that is used, due to its extreme resistance to high temperatures. These are almost the replica of the filament bulb lights, except that these headlights use halogen gases like bromide or iodide inside them.

The tungsten heats up to approximately 2,500° Celsius due to the electrical current and it starts to glow, this is called an incandescent process.

The bulb requires an inert gas and a small amount of a halogen such as iodine or bromine for its work. A halogen bulb is similar to a regular electric bulb used for household purposes. The regular bulb has a filament wire that heats up and emits light. But the halogen lamp uses halogen gas to increase brightness.

The primary objective of a halogen gas involves extending the life of the tungsten filament.

Halogen headlights are found to be used on approximately 80% of the cars on the road today which makes them the most commonly available type of headlights.

The lifespan of these headlights ranges from about 450 hours to 1000 hours. The reason for the lifespan is because of heat and efficiency, which are both big factors.

The lamp used is also known as quartz halogen and tungsten halogen lamp. It is a processed form of the incandescent lamp.

The filament consists of ductile tungsten and is located in a gas-filled bulb just like a standard tungsten bulb. While operating at a higher filament temperature, results in more lumens output per watt input, a tungsten-halogen lamp has a much longer brightness lifetime than the other similar filaments operating without the halogen regeneration cycle.

The gas used in a halogen bulb is at high pressure (7-8 ATM) and the glass bulb is made up of fused quartz, high-silica glass, or aluminosilicate.

The glass used is stronger than the standard glass as it helps to contain the high pressure. This lamp is preferred as an industry standard for work and film/television lighting due to its moderate size and high-lumen output.

The halogen lamp is being replaced slowly by the white LED lamp, the miniature HID and fluorescent lamps, etc.

Advanced technology for increased efficiency halogens with 30+ lumens/watt is being brought into the market to change the sales decline in the future.

Halogen Headlight Advantages:

The advantages of Halogen-based headlights are that the lamps are small and lightweight, the production cost is low, and they do not use mercury as in CFLs i.e fluorescent or mercury vapor lights.

These also have a better color temperature than standard tungsten (2800-3400 K), it is more similar to the sunlight than the “orange” standard tungsten.

It can sustain for a longer amount of time than conventional incandescent.

Moreover, it does require any warm-up time and can be switched on to full brightness instantly. It is also dimmable.

The disadvantage of Halogen Headlight:

The disadvantages related to Halogen headlights include extremely hot surfaces which are easily capable of causing severe burns if the lamp is touched, the lamp is too sensitive to oils left by the human skin and if you touch it the oil left behind will heat up once the bulb is activated and the oil may cause an imbalance resulting in a rupture of the bulb.

The bulb also has a chance of blowing up and sending hot glass shards outward. A screen or layer of glass on the outside of the lamp is required to protect the users.

#3. HID

HID is an abbreviation for High-intensity discharge lamps which are a type of electrical gas-discharge lamp producing light utilizing an electric arc. It is between tungsten electrodes housed inside a translucent or transparent fused quartz or fused alumina arc tube.

The tube contains noble gas and often also consists of a suitable metal or metal salts. It is also known by the means of xenon lights due to the involvement of the noble gas in the working.

The filament does not get heated up, instead, xenon gas is electrically charged. HID produces a bluish-white light that is similar to natural light.

The arc’s initial strike is enabled by the noble gas. Once the arc starts, it heats up and evaporates the metallic mixture.

Its presence in the arc plasma helps to increase the intensity of visible light which is produced by the arc for given power input.

The metals tend to emit many spectral lines in the visible part of the spectrum. High-intensity discharge lamps are considered a type of arc lamp.

Different types of chemical variations are used in the arc tubes of HID lamps. It is dependent on the desired characteristics of light intensity, color rendering index (CRI), energy efficiency, correlated color temperature, and lifespan.

Varieties of HID lamps include Mercury halide lamps, Metal halide (MH) lamps, Ceramic MH lamps, sodium vapor lamps, and xenon short arc lamps.

The light-producing element of the lamp types is a stabilized arc discharge. It is contained within a refractory envelope arc tube with a wall loading of more than 3 W/cm².

Mercury-vapor lamps were the first commercially available HID lamps and they produced a bluish-green light. But the latest versions of these can produce light with a less defined color tint.

Metal-halide and ceramic metal-halide lamps can be used to obtain white light useful for applications such as entertainment and sports lighting.

Low-pressure sodium-vapor lamps are more efficient as they tend to produce a deep yellow-orange light and have an effective color rendering index (CRI) of about zero. Items viewed under low-pressure sodium vapor light appear monochromatic which makes them effective and useful as photographic safelights.

High-pressure sodium lamps are the opposite as they tend to produce a much whiter light with a characteristic orange-pink cast.

Advantages & Disadvantages:

The advantages of HID lights are that these lights are about 2 1/2 times more powerful than comparable standard halogen lights. They tend to produce a white-hot beam against that of the sunlight in halogen.

The disadvantages are that like fluorescent lamps, even HID lamps require the ballast to start and maintain the arc.

The methods used for the initial striking of the arc vary, namely mercury-vapor lamps and some metal-halide lamps use the third electrode near one of the main electrodes to get started, while other lamp styles are notably started using pulses of high voltage.

HID lamps have a small delay before lighting up and take some time to achieve full brightness.

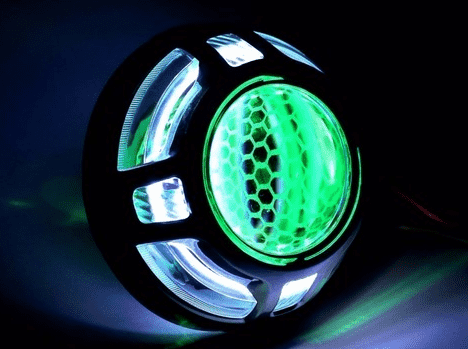

#4. LED:

This lighting is an advanced technology used to produce crystal-clear light. LED abbreviates for Light Emitting Diode. It is a simple semiconductor that emits light when current is passed through it.

The current in the semiconductor flows only in one direction. The energy drawn from the battery to emit light is less than the halogen and xenon lights in the case of the LED, as it requires relatively little current to illuminate.

The working of the LED lights is based on the flow of current from cathode to anode passing through the semiconducting material, which is a material with conductivity somewhere between metal and rubber.

It is made by mixing a material that can conduct electricity with an insulating material.

The semiconductor then emits photons which then illuminate the road ahead. These headlights produce a brighter, whiter light and tend to put out around 2,000-4,000 lumens.

As a result, LED lights illuminate more areas and get a clear view.

The classic standard variant LED is cylindrical and is a hemisphere at the end where the light is emitted.

A simple LED contains parts such as an LED chip, a reflector tray connected to the cathode, a gold wire connected to the anode, and a plastic lens to combine and hold the components.

Different types and designs are present in LEDs. The most important ones are leaded LEDs, Superflux, SMD, High power, and COB.

A Leaded LED consists of a cathode shorter than the anode. SuperFlux LEDs are more powerful than leaded LEDs, achieving broader beam angle, hood heat dissipation, and long service life.

SMD i.e Surface Mounted Device is a diode that is surface mounted. These are insensitive and shine intensively.

These LEDs usually consist of three to four chips with contacts soldered to the connection surface.

The advantages of LEDs are that they are energy efficient and produce very little heat, provide superior durability with a long-predicted lifetime of about 20000 hours which is almost 20 hours longer than halogen lights, provide an alternative method for daytime running lights, and provide a clear and effective view of the road at night.

Although the brightness is not as significant as HID, LEDs are around 2.75 times stronger and have brighter light than halogen.

These also have a fast switch on-off capability and require low operational voltage. The disadvantages of LEDs include the requirement of an extra cooling component for the small amount of heat emitted, difficulty in designing an optimum LED lamp, and incredibly expensive and complex design.

#5. Matrix Headlights

A matrix is an advanced form of LED light. These consist of many individual smaller LED lights working in unison to make a headlight. All of these smaller LEDs are controlled independently.

Termed “smart” lights, it is also called Adaptive LED or Pixel lighting. It has a camera mounted on the inside rearview mirror to detect the lights of oncoming vehicles.

An onboard computer detects and registers the lights from the incoming vehicle and sends the signal to the housing.

The system turns OFF the individual LEDs that affect the lighting of the oncoming vehicle while the remaining LEDs are ON.

As the vehicle approaches, the individual LEDs cover up the gap, lighting ahead.

The advantage of Matrix lights is that the driver can use the high beam lights without needing to switch between low beams, even when there is incoming traffic.

The disadvantage of such lights is that many components need to work in unison for the lighting system to work and as a result, if one of the components fails the whole system can fail.

#6. Laser

The use of lasers is the latest technology introduced in the automobile industry. The Laser headlights contain one or more solid-state laser diodes, mounted inside the headlight.

These emit blue lasers fired at a yellow phosphor, similar to that used in white LEDs. A powerful, vibrant white light that can then be bounced off reflectors and out of the headlights towards the road is produced.

The regular low-beam lamp LED is used with the laser to create an incredibly bright and focused spot which is used for high beams.

This provides illumination up to 600 meters ahead of the vehicle, double that of conventional LED high beams.

The lights use indium gallium nitride diode lasers with the layers above with power levels above worth 1 watt.

It is based on light from 3 sources that fall on a mirror inside the headlight housing.

The blue laser out of this is reflected from the mirror through a lens that contains yellow phosphorus and this yellow phosphorus is excited by the blue laser light and produces a white beam.

The reflected white light is reflected on the shiny reflective surface which throws the light through the lens on the road.

The advantages of Laser lights are that they are about 1000 times more intense than LED lights and consume nearly half the energy required (30% more efficient). This leads to less lead formation on batteries and better life. The size of the laser light source is smaller than that of LEDs.

The disadvantages to be mentioned are that these are the most expensive of options, almost three times the price of xenon lights, and are not as precise as the LEDs. Laser headlights are not available as dual beams and generate a considerable amount of heat.

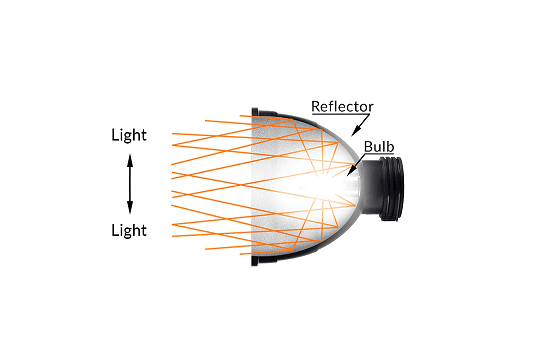

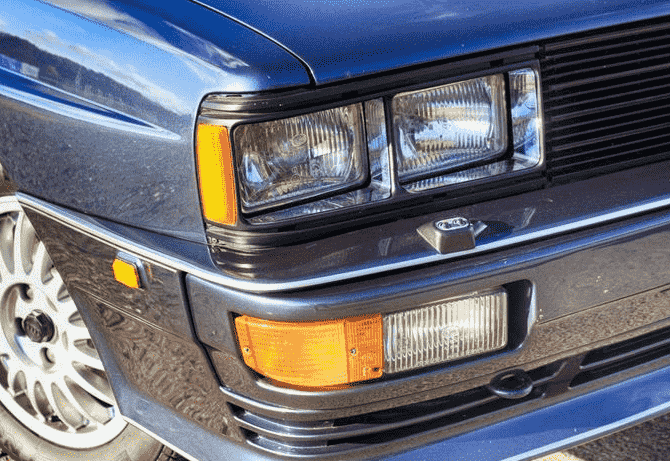

#7. Reflector headlights

Reflector headlights were the lighting standards until 1985. The design of reflector headlights involved a bowl-like casing that consisted of a reflective headlight and mirrors attached around the headlight to reflect the light.

These were called sealed beam headlights initially due to the lights having a fixed casing.

There was a lens in front of the headlight which determined the shape of the beam of light. Also, the bulb and lens were in a single housing and the whole housing was to be replaced in case of any damage.

Further improvements have led to the lens design being replaced by the reflective mirrored surface which guides the beam of light.

This advancement separated the single housing system and the bulb can be replaced individually in case of damage.

The Advantages of reflector headlights are that it takes up smaller space due to their compact size and has cheaper maintenance.

Disadvantages include non-compatibility to high output bulbs and low beam is often less distinct for the oncoming traffic. The beam of light produced is uneven with a lot of weak and intense spots.

#8. H4 Conversions

These are advanced forms of reflector headlights. Similar to modern reflectors, the bulb and housing assembly are separate in this type of light.

However, instead of a sealed case, H4 conversions use dual filament-type bulbs. These can adapt to HID and LED bulbs which is not the case with reflectors.

The bulbs can also be replaced in case of burnout and the entire assembly does not need to be replaced.

The advantages of these include an easy replacement and brighter illumination.

The drawbacks are that since these are reflector-type lights, the light produced is uneven with hot spotting, scattered, and can cause blinding of oncoming traffic.

#9. Projector Headlights

Projector lights are an advanced form of lights that were initially used in luxury cars only. Halogen and HID both have projector headlight versions.

The design of these headlights consists of a metal shield in front of the headlight that helps focus the light in a specific direction.

These also have mirrors, just like in the reflector headlights, to help reflect and increase the density of light. Moreover, it consists of a curved lens that works as a magnifying glass.

As a result, these have an increased brightness of the beam of light and provide better illumination.

The system also contains a cutoff shield, just in case to make sure that the angle of the light beam produced by projector headlights is correct and prevents the light from bleeding outside the intended radius.

The advantages of projector lights are that they are brighter than conventional reflector lights. The lens tilts the beam of light downwards onto the road so that it does not affect other vehicles or pedestrians on the road. The beam of light produced is a lot more even with no weak or intense spots.

The disadvantage of projector headlights is that they produce a different beam of light as compared to reflector headlights and it is difficult to adapt to the lighting.

#10. Quad Headlights

Quad headlights are commonly seen in modern cars and larger vehicles. It has wider housing and consists of two headlight bulbs per headlight. The two bulbs are for the high beam and low beam respectively.

As a result, these consist of two headlight connectors each and each connector has two wires connected to it.

The advantage of this high output system is that it provides stronger light than non-quad lights due to its dual working nature.

The drawbacks of the quad headlights are that they may result in high maintenance if the system fails. Also, a quad headlight cannot be switched to any non-quad type of light due to its unique dual wiring and it needs to be replaced with a quad headlight itself.

#11. Non-quad headlights

Non-quad lights are commonly seen in smaller cars. These consist of a smaller housing and a single headlight bulb inside the housing of each headlight.

The single headlight bulb works as the high beam and low beam. It consists of a single headlight bulb connector and has three wires connected to it.

The advantage of these headlights is that it requires a minimal amount of energy to work and maintenance is cheap.

The disadvantage is that it is not as bright as quad lights and as a result, does not provide clear visibility.

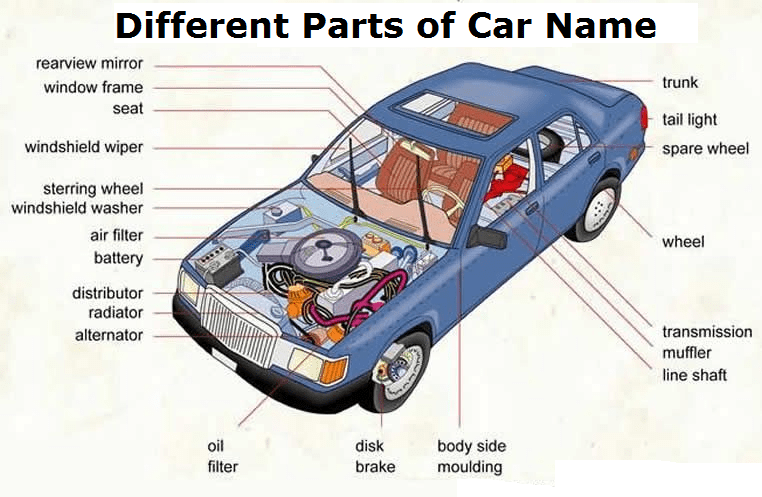

#12. Driving & Interior lamps

Driving and Interior lamps are located inside the car and these are used for the driver to locate the car parts inside and also help to view maps or directions.

We can also say the interior lamps include instrument panel lights, various warning indicator lights, and compartment lights. Other different types of keyhole lights, map lights, radio dial lights, and clock lights are also provided in some cars.

#13. Parking lights

As the name itself indicates Parking that means this light is being used when we are going to park the vehicle. This is low-intensity parking lights are usually provided in the front of the car.

The parking light helps to provide a signal for another object and therefore it avoids the accident.

#14. Direction-signal lights

This light helps in turning the vehicle. It gives signals to the vehicle coming from the front or rear. In addition, some special signal lights are also used.

#15. Blinker lights

Blinker light is also an important type of light and It is used when the car or other vehicle stop on the highway. This light is much more noticeable than any other steady light and provides a warning to other approaching vehicles or cars.

#16. Tail Light

The tail light helps at the night or you can say when the sunset. When the other vehicles coming from behind it are able to see it. The tail light is on all the time at night when the car is running.

#17. Brake Light

It is a very important type of light and is also known as a stop light. The brake light is located at the rear of the car and becomes on when brakes are applied.

When you press the brake light automatically gets on to give the signal to another vehicle behind it and thus it avoids the accident.

Discussion about this post